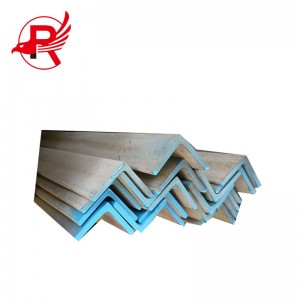

I-100x100x6 SS41B Slotted Angle Bar Line Structural Galvanized Steel Angle Bar yoYilo lweFence

Intsimbi ye-engile egayiweyoYahlulwe yaba yintsimbi ye-angle ekhanyisiweyo eshushu kunye nentsimbi ye-angle ekhanyisiweyo ebandayo. Intsimbi ye-angle ekhanyisiweyo eshushu ikwabizwa ngokuba yintsimbi ye-angle ekhanyisiweyo eshushu okanye intsimbi ye-angle ekhanyisiweyo eshushu. I-cold-dip galvanized coating ikakhulu iqinisekisa unxibelelwano olupheleleyo phakathi komgubo we-zinc kunye nentsimbi ngomgaqo we-electrochemical, kwaye ivelisa umahluko onokubakho we-electrode wokulwa nokugqwala.

Intsimbi ye-angle egqunyiweyo eshushu ikwabizwa ngokuba yi-hot-dip galvanized angle steel okanye i-hot-dip galvanized angle steel. Yenzelwe ukuntywilisela intsimbi ye-angle emva kokunyibilikisa i-zinc enyibilikisiweyo malunga nama-500 ℃, ukuze umphezulu wentsimbi ye-angle unamathele ngomaleko we-zinc, ukuze kufezekiswe injongo yokulwa nokugqwala, kwaye ifanelekile kwiindawo ezahlukeneyo ezinamandla okugqwala ezifana ne-acid enamandla kunye ne-alkali mist.

Inkqubo: intsimbi ye-angle edityiweyo eshushu Inkqubo: ukugalela intsimbi ye-angle → ukuhlamba ngamanzi → ukuntywiliselwa kwi-plating solvent → ukomisa kunye nokufudumeza kwangaphambili → ukuplata i-rack → ukupholisa → ukucoca → ukugaya → ukugawula i-hot-dip kugqityiwe.

IngqeleIbha yentsimbi ye-Angleisetyenziselwa ukukhusela iintsimbi ekungcoleni. Ngenxa yesi sizathu, kusetyenziswa ugqubuthelo lwe-zinc filler. Lusetyenziswa kumphezulu ukuze lukhuselwe nangayiphi na indlela yogqubuthelo. Emva kokomiswa, kwenziwa ugqubuthelo lwe-zinc filler. Kwigqubuthelo elomileyo. Inomxholo ophezulu we-zinc (ukuya kuthi ga kwi-95%). Ifanelekile kumsebenzi wokulungisa (oko kukuthi, ngexesha lomsebenzi wokulungisa, kuphela apho umphezulu wentsimbi okhuselweyo wonakele, unokuphinda usetyenziswe kwangoko emva kokuba umphezulu ulungisiwe). Inkqubo yokugaya i-cold isetyenziselwa ukuthintela ukungcola kweemveliso ezahlukeneyo zentsimbi kunye nezakhiwo.

Ibha ye-Angle yentsimbi yekhabhoniIntsimbi sisixhobo sokwakha esisetyenziswa kakhulu, esithandwa ngenxa yokuqina kwayo, ukomelela kwayo, kunye nokumelana nokugqwala nokugqwala. Yenziwe ngentsimbi egqunywe ngumaleko we-zinc, eyinika ukhuseleko oluhle kakhulu kwizinto ezibangela imozulu. Nantsi ingqwalasela esondeleyo yentsimbi ye-galvanized angle.

Ulwakhiwo kunye neempawu:

Ii-engile ze-galvanized zenziwe ngentsimbi ethambileyo, ethambileyo kakhulu kwaye kulula ukuyitshixa. Intsimbi idlula kwinkqubo ebizwa ngokuba yi-galvanizing, equka ukuyigquma ngomaleko we-zinc. Olu gquma lubonelela ngomaleko owongezelelweyo wokhuseleko ophucula ukuqina, amandla kunye nokumelana nokugqwala kwentsimbi.

Ibha ye-Angle yentsimbiZihlala ixesha elide kakhulu kwaye ziyamelana nokugqwala, nto leyo eyenza ukuba zilungele ukusetyenziswa kwiindawo ezinzima ezifana neendawo zaselwandle naselunxwemeni. Iingubo ze-zinc zikwanika intsimbi inkangeleko ekhazimlayo nenomtsalane, nto leyo eyenza ukuba zibe ntle kwiiprojekthi zokwakha nezoyilo.

isicelo:

Intsimbi ye-engile ye-galvanized sisixhobo sokwakha esisebenziseka ngeendlela ezahlukeneyo esinokusetyenziswa ngeendlela ezahlukeneyo. Sisetyenziswa kakhulu ekwenzeni imiqadi, izakhelo kunye nezibiyeli kwishishini lokwakha, kunye nasekuveliseni iinqaba zombane, ucingo kunye nezinye izinto zeziseko.

Ii-engile zentsimbi ezigayiweyo zikwasetyenziswa kushishino ekwenzeni oomatshini, izixhobo kunye nezinto ezisetyenziswayo. Amandla ayo aphezulu kunye nokumelana nokugqwala kwenza ukuba ilungele ukusetyenziswa kwiindawo zoshishino ezinzima ezichatshazelwa ziikhemikhali, umswakama, kunye nezinye izinto ezibangela ukugqwala.

Ukongeza, ii-engile zentsimbi ezirhangqiweyo zisetyenziswa ekwenzeni izixhobo zasekhaya, izixhobo kunye nezixhobo. Inkangeleko yayo ekhangayo kunye nokuqina kwayo kwenza ukuba ilungele ukusetyenziswa kwiimveliso ezifana neeyunithi zeeshelufu, iibrakethi kunye nezixhobo zasekhaya.

inzuzo:

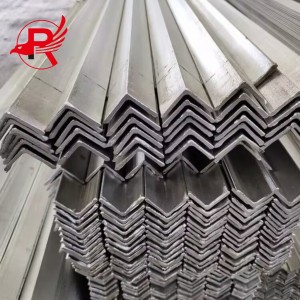

Xa kuthelekiswa nezinye izinto zokwakha, intsimbi ye-galvanized angle ineengenelo ezininzi. Ihlala ixesha elide kakhulu, ayidli mhlwa kwaye inokumelana neemeko ezinzima ngaphandle kokuwohloka. Ikwanomtsalane kwaye kulula ukuyisebenzisa, nto leyo eyenza ukuba ibe lukhetho oludumileyo kubayili bezakhiwo, abayili kunye nabakhi.

Ukongeza, ii-engile zentsimbi ezigayiweyo zibiza kakhulu kwaye azidingi ukugcinwa kakhulu, nto leyo eyenza ukuba zibe lukhetho oluthandwayo kwiintlobo ngeentlobo zezicelo zokwakha. Ukuxhathisa kwayo umhlwa kunye nokugqwala kuthetha ukuba ihlala ixesha elide kunentsimbi yendabuko, oko konga imali ngokuhamba kwexesha.

1. Iindleko zokucubungula eziphantsi: iindleko zokufaka i-hot-dip galvanizing kunye ne-anti-rust ziphantsi kunezo zezinye iingubo zokupenda;

2. Ihlala ixesha elide kwaye ihlala ixesha elide: intsimbi ye-angle ye-galvanized angle ene-hot-dip ineempawu zokukhazimla komphezulu, umaleko we-zinc ofanayo, akukho plating ilahlekileyo, akukho dripping, i-adhesion enamandla kunye nokumelana nokugqwala okunamandla. Kwimeko-bume yasezidolophini, ubukhulu obuqhelekileyo be-hot-dip galvanized anti-rust bunokugcinwa Ngaphezulu kweminyaka engama-50 ngaphandle kokulungiswa; kwiindawo zasezidolophini okanye kwiindawo ezikude nolwandle, umaleko oqhelekileyo we-hot-dip galvanized anti-rust unokugcinwa iminyaka engama-20 ngaphandle kokulungiswa;

3. Ukuthembeka okulungileyo: ikhonkco lesinyithi phakathi komaleko we-galvanized kunye nezinto zentsimbi liba yinxalenye yomphezulu wentsimbi, ngoko ke ukuqina kwengubo kuthembeke ngakumbi;

4. Ukuqina kwengubo kuqinile: umaleko we-galvanized wenza isakhiwo esikhethekileyo se-metallurgical, esinokumelana nomonakalo woomatshini ngexesha lokuthuthwa nokusetyenziswa;

5. Ukhuseleko olupheleleyo: yonke indawo yeendawo ezifakwe iplastiki inokugqunywa nge-zinc, nokuba kusezingxondorheni, iikona ezibukhali kunye neendawo ezifihlakeleyo zinokukhuseleka ngokupheleleyo;

6. Gcina ixesha kunye nomgudu: inkqubo yokufaka i-galvanizing ikhawuleza kunezinye iindlela zokwakha i-coating, kwaye ingathintela ixesha elifunekayo lokupeyinta kwindawo yokwakha emva kokufakwa.

Intsimbi ye-engile ye-galvanized isetyenziswa kakhulu kwiinqaba zamandla, iinqaba zonxibelelwano, izixhobo zodonga lwekhethini, ukwakhiwa kweeshelufu, oololiwe, ukhuseleko lwendlela, iipali zezibane zesitalato, izinto zaselwandle, izinto zesakhiwo sentsimbi, izibonelelo ezincedisayo zesitishi esingaphantsi, ishishini lokukhanya, njl.

| Igama lemveliso | AiBhari ye-ngle |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njl. |

| Uhlobo | Umgangatho we-GB, Umgangatho waseYurophu |

| Ubude | I-Standard 6m kunye ne-12m okanye ngokweemfuno zomthengi |

| Ubuchule | Ishushu Eqengqelekayo |

| Isicelo | Isetyenziswa kakhulu kwizinto zodonga lwekhethini, ulwakhiwo lweeshelufu, oololiwe njl.njl. |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.