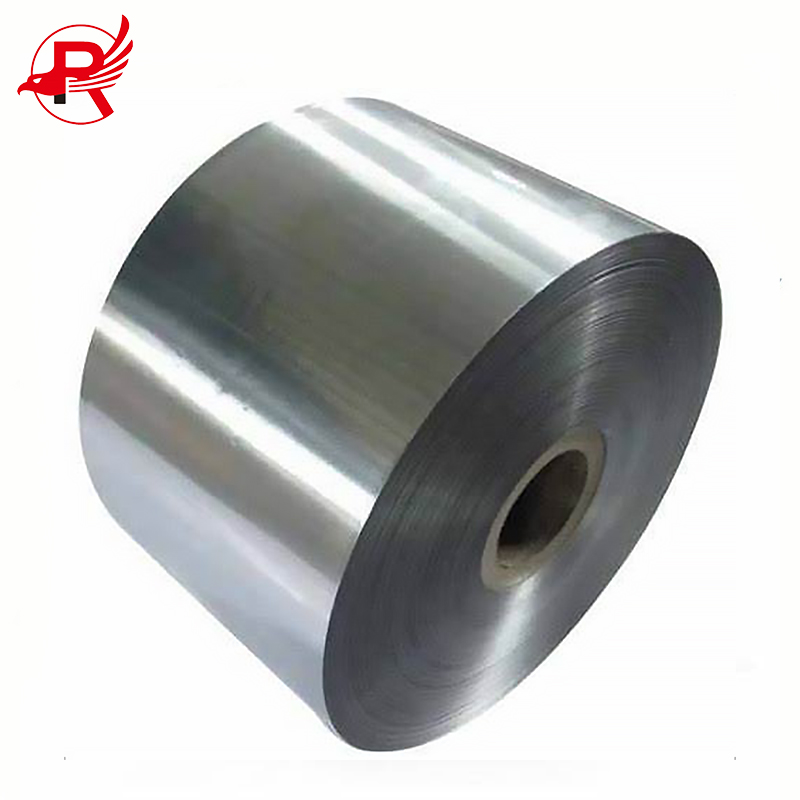

Ikhoyili ye-aluminium alloy ye-6061 yokwakhiwa kwezakhiwo esetyenzisiweyo

| 1) I-1000 Series Alloy (Ngokubanzi ibizwa ngokuba yi-aluminium ecocekileyo yorhwebo, Al> 99.0%) | |

| Ubunyulu | 1050 1050A 1060 1070 1100 |

| Umsindo | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/ H26/H36 H18/H28/H38 H114/H194, njl. |

| Inkcazo | Ubukhulu≤30mm; Ububanzi≤2600mm; Ubude≤16000mm OKANYE Ikhoyili (C) |

| Isicelo | Isivalo, Izixhobo zeMizi-mveliso, Indawo yokugcina izinto, Zonke iintlobo zeekhonteyina, njl. |

| Uphawu | Ukuqhuba kakuhle kwe-Lid Shigh, ukusebenza kakuhle okumelana nokugqwala, ubushushu obuphezulu obufihlakeleyo yokunyibilika, ukubonakalisa okuphezulu, ipropati yokuwelda imithombo, amandla aphantsi, kwaye hayi ifanelekile kunyango lobushushu. |

| 2) I-3000 Series Alloy (Ngokubanzi ibizwa ngokuba yi-Al-Mn Alloy, i-Mn isetyenziswa njengesixhobo esiphambili se-alloy) | |

| I-alloy | 3003 3004 3005 3102 3105 |

| Umsindo | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/ H36 H18/H28/H38 H114/H194, njl. |

| Inkcazo | Ubukhulu≤30mm; Ububanzi≤2200mm Ubude≤12000mm OKANYE Ikhoyili (C) |

| Isicelo | Umhombiso, isixhobo sesinki yobushushu, iindonga zangaphandle, indawo yokugcina izinto, amashiti okwakha, njl. |

| Uphawu | Ukumelana nokugqwala okuhle, akufanelekanga ukunyangwa ngobushushu, kwaye kumelana nokugqwala okuhle ukusebenza kakuhle, ipropati yokuwelda imithombo, iplastiki elungileyo, amandla aphantsi kodwa afanelekile yokuqinisa umsebenzi obandayo |

| 3) I-5000 Series Alloy (Ngokubanzi ibizwa ngokuba yi-Al-Mg Alloy, i-Mg isetyenziswa njengesixhobo esiphambili se-alloy) | |

| I-alloy | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Umsindo | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, njl. |

| Inkcazo | Ubukhulu≤170mm; Ububanzi≤2200mm; Ubude≤12000mm |

| Isicelo | Ipleyiti yeBanga loLwandle, iRing-Pull Can End Stock, iRing-Pull Stock, iiMoto Iishiti zomzimba, iBhodi yangaphakathi yeMoto, isiciko esikhuselayo kwinjini. |

| Uphawu | Zonke iingenelo ze-aluminium alloy eqhelekileyo, amandla aphezulu okuxinana kunye namandla okuvelisa, ukusebenza kakuhle okumelana nokugqwala, ipropati yokuwelda kwimithombo, amandla okudinwa kwemithombo, kwaye ifanelekile kwi-anodic oxidation. |

| 4) I-6000 Series Alloy (Ngokubanzi ibizwa ngokuba yi-Al-Mg-Si Alloy, i-Mg kunye ne-Si zisetyenziswa njengezinto eziphambili ze-alloy) | |

| I-alloy | 6061 6063 6082 |

| Umsindo | KA, njl. njl. |

| Inkcazo | Ubukhulu≤170mm; Ububanzi≤2200mm; Ubude≤12000mm |

| Isicelo | Iimoto, iAluminiyam yeenqwelo moya, iMbumbi yezeMizi-mveliso, iiComponents zeMechanical, Iinqanawa zoThutho, Izixhobo zeSemiconductor, njl.njl. |

| Uphawu | Ukusebenza kakuhle okumelana nokugqwala, ipropati yokuwelda imithombo, ukukwazi ukunyibilika kakuhle, kulula ukutshiza, ukufaka umbala kwi-oxidation yemithombo, ukusebenza kakuhle komatshini. |

Njengezinto ezisebenza ngeendlela ezininzi, iikhoyili ze-aluminium zinokusetyenziswa ngeendlela ezahlukeneyo kwiindawo ezahlukeneyo.

Okokuqala, kwicandelo lokwakha, iikhoyili ze-aluminium zihlala zisetyenziswa ekwakheni udonga lwangaphandle, uphahla, iisilingi, izakhelo zeefestile, njl. Ngenxa yokuba iikhoyili ze-aluminium zinokumelana kakuhle nemozulu kunye neempawu zokuhombisa, zinokuhlangabezana neemfuno zenkangeleko kunye nokuqina kwezakhiwo.

Okwesibini, kwicandelo lezothutho, iikhoyili ze-aluminium zihlala zisetyenziselwa ukwenza amaqokobhe, iiphaneli zomzimba, iindawo zangaphakathi, njl.njl. zezithuthi ezifana neemoto, oololiwe, kunye neenqwelo moya. Ubunzima beekhoyili ze-aluminium buyanceda ekunciphiseni ubunzima besithuthi kunye nokuphucula ukusebenza kakuhle kwepetroli.

Ukongeza, kwicandelo lezixhobo ze-elektroniki nezombane, iikhoyili ze-aluminium zihlala zisetyenziselwa ukwenza iibhokisi zebhetri, ii-radiator, ii-casing zemveliso ze-elektroniki, njl. Iipropati zokuqhuba umbane kunye nokusasazwa kobushushu kweekhoyili ze-aluminium zenza ukuba ibe yinto ebalulekileyo kwishishini le-elektroniki nelombane.

Ukongeza, kwicandelo lokupakisha, iikhoyili ze-aluminium zisetyenziswa kakhulu ekupakisheni ukutya, ekupakisheni amayeza, njl. Ngenxa yokuba iikhoyili ze-aluminium zinokumelana okuhle nokutywinwa kunye nokuxinana, zinokukhusela ngokufanelekileyo umgangatho kunye nokhuseleko lwezinto ezipakishiweyo.

Ngokubanzi, iikhoyili ze-aluminium zinezicelo ezibalulekileyo kulwakhiwo, uthutho, izixhobo ze-elektroniki, ukupakisha kunye nezinye iinkalo. Ubunzima bayo obulula, ukumelana nokugqwala, kunye nokulula ukuyilungisa kuyenza ibe yenye yezinto eziyimfuneko kakhulu kumashishini ahlukeneyo.

| UBUBALA(MM) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1000 | 1 | 2 | 3 | 4 | Okunye |

| 1219 | 1 | 2 | 3 | 4 | Okunye |

| 1220 | 1 | 2 | 3 | 4 | Okunye |

| 1500 | 1 | 2 | 3 | 4 | Okunye |

| 2000 | 1 | 2 | 3 | 4 | Okunye |

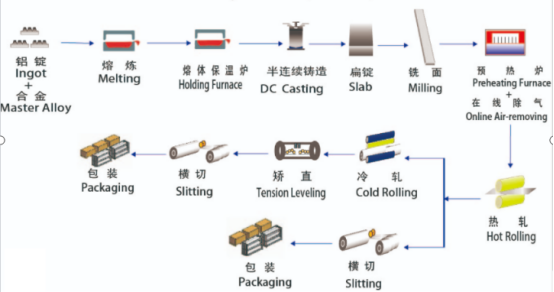

Imveliso yeintsimbi yealuminiyamidla ngokuhamba ngamanyathelo amaninzi. Okokuqala, ukuqala kwii-ingots ze-aluminium, ngokunyibilikisa kunye nokuphoswa okungapheliyo, kufunyanwa i-aluminium engamanzi ehlangabezana neemfuno. Okulandelayo, i-aluminium enyibilikisiweyo iphoswa kwi-slab ye-aluminium ngenkqubo yokuphoswa nokuphoswa okuqhubekayo, kwaye emva koko ubukhulu buncitshiswa kancinci ngomatshini wokuphoswa okuqhubekayo ukwenza ikhoyili ye-aluminium efunekayo. Emva koko, ikhoyili ye-aluminium iyacinywa kwaye i-annealed ukuze kulungiswe ulwakhiwo lwayo kunye neempawu kunye nokuphucula amandla ayo kunye ne-plasticity. Okokugqibela, iikhoyili ze-aluminium zinokugqunywa ukuze kwandiswe ukumelana nokugqwala okanye iimpawu zokuhombisa kwiindawo zazo. Inkqubo yonke yemveliso ifuna ulawulo oluqinileyo ukuqinisekisa ukuba umgangatho wemveliso kunye nokusebenza kuyahlangabezana neemfuno ezisemgangathweni. Kwangaxeshanye, ukhuseleko lokusingqongileyo, ukusetyenziswa kwamandla kunye nezinye izinto nazo ziingxaki ekufuneka ziqwalaselwe ngexesha lenkqubo yemveliso.

Nazi ezinye izinto ezibalulekileyo ekufuneka uziqwalasele xa uhlolaikhoyili yealuminiyam:

1. Ubungakanani: Jonga ubungakanani beikhoyili ye-aluminium alloyngokuchasene nemigaqo enikwe ngumenzi. Qinisekisa ukuba zinobukhulu, ububanzi kunye nobude obuchanekileyo.

2. Umgangatho womphezulu: Jonga umphezulu wekhoyili ukuba awunamikrwelo, uqhekeko okanye ezinye iziphene. Umphezulu kufuneka uthambe ngaphandle komonakalo obonakalayo.

3. Ukuhambelana kombala: umbala wekhoyili kufuneka uhambelane kuyo yonke ikhoyili. Naluphi na utshintsho kumbala lunokubonisa ingxaki kwinkqubo yokuvelisa.

4. Ubukhulu bokugquma: Ukuba ikhoyili inesigqumathelo, ubukhulu bokugqumathelo kufuneka buhlolwe ukuqinisekisa ukuba iyahlangabezana neemfuno ezichaziweyo. Ubukhulu bokugqumathelo obuncinci kakhulu okanye obukhulu kakhulu bunokuchaphazela ukuqina nokusebenza kwemveliso.

5. Ukwakhiwa kweekhemikhali: hlalutya ukwakheka kweekhemikhali ze-aluminium ukuqinisekisa ukuba iyahlangabezana nemigangatho efunekayo. Oku kuquka ukujonga ukungcola okanye ezinye izinto ezinokuchaphazela umgangatho wemveliso.

6. Ukupakishwa kunye nokulebhelishwa: Qinisekisa ukuba imiqulu ipakishwe kakuhle kwaye ilebhelishwe ukuze ithunyelwe kwaye igcinwe. Ukupakishwa kufuneka komelele kwaye kuyilwe ukukhusela ikhoyili ngexesha lokuthuthwa.

7. Inkqubo yokuvelisa: Inkqubo yokuvelisa iyahlolwa ukuqinisekisa ukuba iyahlangabezana nemigangatho efunekayo kwaye zonke izixhobo zigcinwa kakuhle kwaye zisebenza kakuhle.

Inkqubo yokuhlola esebenzayo iya kunceda ekuchongeni naziphi na iingxaki ezinokubakho ngemveliso kwaye iqinisekise ukuba iyahlangabezana nemigangatho yomgangatho efunekayo.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.