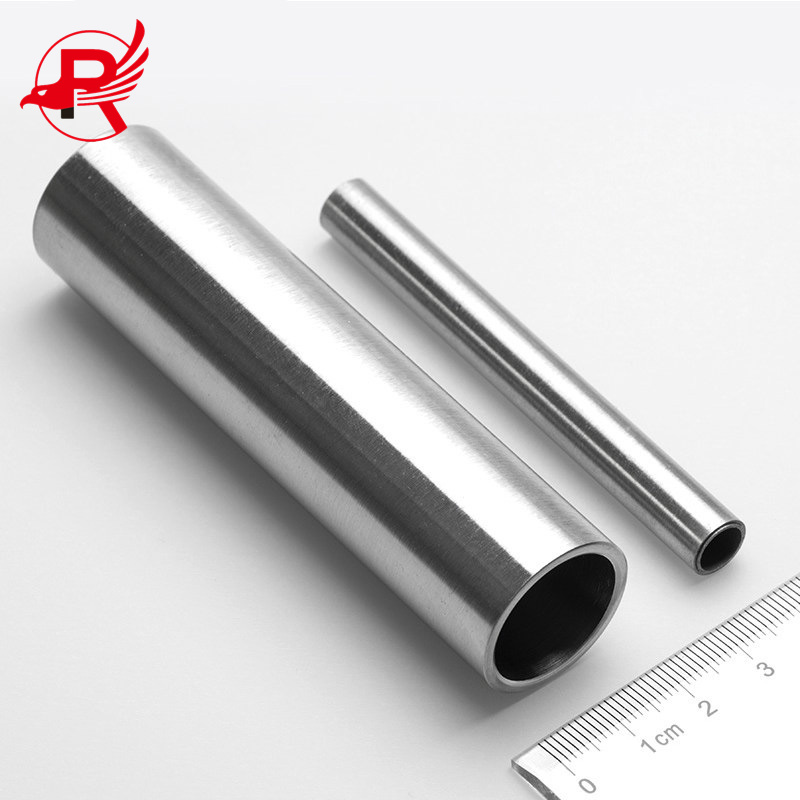

I-1mm 2mm Umgangatho oPhakamileyo 410 420 430 440 Ipayipi yentsimbi engagqwaliyo SS Tube

| i-tem | 410 420 430 440 Umbhobho weNtsimbi Engagqwaliyo |

| Umgangatho | I-JIS, i-AiSi, i-ASTM, i-GB, i-DIN, i-EN |

| Indawo yemvelaphi | iTshayina |

| Igama lebrand | UBUKHOSI |

| Uhlobo | Akukho mthungo / Ukuwelda |

| Ibanga lentsimbi | Uthotho lwe-200/300/400, 904L S32205 (2205),S32750(2507) |

| Isicelo | Ishishini leekhemikhali, izixhobo zoomatshini |

| Inkonzo Yokucubungula | Ukugoba, Ukuwelda, Ukuhombisa, Ukubethela, Ukusika, Ukubumba |

| Ubuchule | Iqengqiwe ngobushushu/iqengqiwe ngokubandayo |

| Immimiselo yokuhlawula | I-T/T (30%IDEPOSIT) |

| Ixesha lexabiso | I-CIF CFR FOB EX-WORK |

Umbhobho wentsimbi engagqwaliyo luhlobo lwentsimbi ende engqukuva engenanto, esetyenziswa kakhulu kwiipayipi zothutho lwemizi-mveliso ezifana nepetroleum, imboni yeekhemikhali, unyango lwezonyango, ukutya, imboni yokukhanya, izixhobo zoomatshini, njl.njl., kunye nezixhobo zesakhiwo soomatshini. Ukongeza, xa amandla okugoba kunye nokujika kwemithambo efana, ubunzima bulula, ngoko ke ikwasetyenziswa kakhulu ekwenziweni kweendawo zoomatshini kunye nezakhiwo zobunjineli. Ikwasetyenziswa njengefenitshala kunye nezixhobo zasekhitshini, njl.njl.

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Iinxalenye zeekhemikhali zePipe yentsimbi engagqwaliyo

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa iindlela ezahlukeneyo zokucubungula ukuqengqeleka okubandayo kunye nokuphinda kusetyenzwe umphezulu emva kokuqengqeleka, ukugqitywa komphezulu wentsimbi engagqwaliyoibhaii-s zinokuba neentlobo ezahlukeneyo.

Kukho iintlobo ezininzi zonyango lomphezulu wepayipi yentsimbi engagqwaliyo, nganye ineempawu zayo ezikhethekileyo kunye neenzuzo zayo.

Enye yezona ndlela zixhaphakileyo zonyango lomphezulu kwipayipi yentsimbi engagqwaliyo lunyango lwe-2B. Olu nyango lomphezulu lufezekiswa ngokuqengqa ishiti yentsimbi engagqwaliyo ngokubandayo uze uyifake. Umphezulu ophumayo unomphetho ogudileyo, ongacwebezeliyo, ofanelekileyo ukusetyenziswa apho ubuhle bungengombandela ophambili.

Esinye isiphetho esidumileyo sepayipi yentsimbi engagqwaliyo kukugqitywa okuxutyiweyo. Esi siphetho sifezekiswa ngokusebenzisa ibrashi yocingo ukwenza imigca ethe nkqo okanye ethe tye kumphezulu wepayipi yentsimbi engagqwaliyo. Ukugqitywa okuxutyiweyo kudla ngokusetyenziswa kwiindawo apho ubuhle buyinto ebalulekileyo, njengokusetyenziswa kwezakhiwo okanye ukuhombisa. Ukongeza kwi-2B kunye nonyango lomphezulu oxutyiweyo, iipayipi zentsimbi engagqwaliyo nazo zinezinye iintlobo zonyango lomphezulu, njengonyango lomphezulu we-BA kunye nonyango lomphezulu wesibuko.

Ukugqitywa kwe-BA kufezekiswa ngokufaka intsimbi engagqwaliyo ngokukhanyayo, okubangela ukuba umphezulu ukhanye kakhulu. Isiphumo sesipili sifezekiswa ngokupolisha umphezulu wentsimbi engagqwaliyo ube mhlophe kakhulu, nto leyo ebangela ukuba ubonakale ngathi sisipili.

Ukukhethwa kokugqitywa komphezulu wepayipi yentsimbi engagqwaliyo kuxhomekeke kwizinto ezininzi ezifana nokusetyenziswa, indawo engqongileyo, kunye nobuhle obufunekayo. Umzekelo, ukugqitywa kwe-2B kunokufaneleka kwiimveliso zoshishino apho ubuhle bungengombandela ubalulekileyo, ngelixa ukugqitywa okuxutywe okanye okubonisiweyo kunokufaneleka kwiimveliso zokwakha okanye zokuhombisa. Ukuqukumbela, ukugqitywa komphezulu wepayipi yentsimbi engagqwaliyo yinto ebalulekileyo echaphazela ukusebenza kwayo kunye nokuqina kwayo.

Unyango olwahlukeneyo lomphezulu lubonelela ngeempawu ezahlukeneyo kunye neenzuzo ngokuxhomekeke kwisicelo kunye nobuhle obufunekayo. Iityhubhu zentsimbi engagqwaliyo zihlala ziyinto ethandwayo kumashishini ahlukeneyo, kwaye ukugqitywa komphezulu wazo kudlala indima ebalulekileyo kwimpumelelo yazo.

Inkqubo ephambili yemveliso: intsimbi engqukuva → ukuhlolwa kwakhona → ukuxobuka → ukugquma → ukubethelela → ukufudumeza → ukugqobhoza → intloko ethe tyaba → ukuhlolwa nokusila → ukuqengqeleka okubandayo (umzobo obandayo) → ukususa amafutha → unyango lobushushu → ukulula → ukusika umbhobho (okumiselweyo ubude) ) → ukuphola/ukudlulisa amanzi → ukuhlolwa kwemveliso egqityiweyo (umbane we-eddy, i-ultrasonic, uxinzelelo lwamanzi) → ukupakishwa kunye nokugcinwa.

Inyathelo lokuqala ekuvelisweniimibhobho yentsimbi engagqwaliyolukhetho lwezinto ezikrwada. Intsimbi engatyiwayo yenziwe ngentsimbi, i-chromium, kunye nezinye izixa ezahlukeneyo zezinye izinyithi ezifana ne-nickel, i-molybdenum, okanye i-titanium. Kubalulekile ukukhetha izinto ezikrwada ezikumgangatho ophezulu ukuqinisekisa umgangatho kunye neempawu zemveliso egqityiweyo.

Nje ukuba izinto eziluhlaza zikhethiwe, inyathelo elilandelayo kwinkqubo yemveliso kukunyibilikisa intsimbi esitovini. Emva koko intsimbi enyibilikisiweyo igalelwa kwisikhunta ukuze kwenziwe i-billet eqinileyo.

Emva koko i-billet ithunyelwa kwindawo yokusila eshushu apho ibunjwa khona ibe yimo efunekayo. Intsimbi eshushu egobileyo emva koko inyangwa ngobushushu obungaphezulu, njengokuqhoboshela okanye ukucima, ukuphucula iimpawu zayo. Ukuqhoboshela kubandakanya ukufudumeza intsimbi kumaqondo obushushu aphezulu uze uyipholise kancinci ukuze ithambe kwaye iqine ngakumbi. Ukuqhoboshela kubandakanya ukupholisa intsimbi ngokukhawuleza ukuze ithambe kwaye iqine ngakumbi.

Inyathelo elilandelayo kwimveliso kukusebenza ngomatshini.Iityhubhu zentsimbi engatyiwayoyenziwe ngomatshini ngokwemilo yayo yokugqibela, ubukhulu kunye nobude kusetyenziswa izixhobo ezahlukeneyo kuquka iilathe, oomatshini bokugaya kunye needrill.

Inkqubo yokugaya ingabandakanya nokususa naziphi na iziphene zomphezulu ezifana noburhabaxa okanye ii-burrs. Emva kwenkqubo yokugaya, imibhobho yentsimbi engagqwaliyo iyacocwa ukuze kususwe naluphi na ungcoliseko ngaphambi kokuba ithunyelwe ukuze ihlolwe. Eli linyathelo elibalulekileyo ekuqinisekiseni ukuba imveliso egqityiweyo iyahlangabezana neemfuno ezifunekayo kunye nemigangatho yomgangatho.

Inkqubo yovavanyo ibandakanya uvavanyo loxinzelelo, uvavanyo lwe-magnetic particles, uvavanyo lwe-ultrasound kunye nolunye uvavanyo. Okokugqibela, umbhobho wentsimbi engagqwaliyo ugqityiwe kwaye ulungele ukuthunyelwa okanye ukufakwa.

Iipayipi zinokunikwa unyango oluhlukeneyo lomphezulu olufana nokupholisha, ukugaya okanye ukupholisha nge-electro ukuze kuphuculwe inkangeleko yazo kunye nokumelana nokugqwala.

Ukuqukumbela, inkqubo yokuvelisa umbhobho wentsimbi engagqwaliyo iyinkimbinkimbi kwaye ifuna ubuchule kunye nengqalelo kwiinkcukacha. Nangona kunjalo, iingenelo zombhobho wentsimbi engagqwaliyo zenza ukuba ube yinto ethandwayo kumashishini ahlukeneyo. Inkqubo yokukhetha izinto ezisemgangathweni, ukunyibilikisa, ukuphosa, ukuqengqeleka, ukunyanga ubushushu, ukwenza i-machining, ukuhlola kunye nokugqiba iphumela kwimveliso eqinileyo, engagqwaliyo enokumelana neemeko ezinzima kwaye inikezele ngeminyaka yenkonzo ethembekileyo.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Umthengi wethu

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.