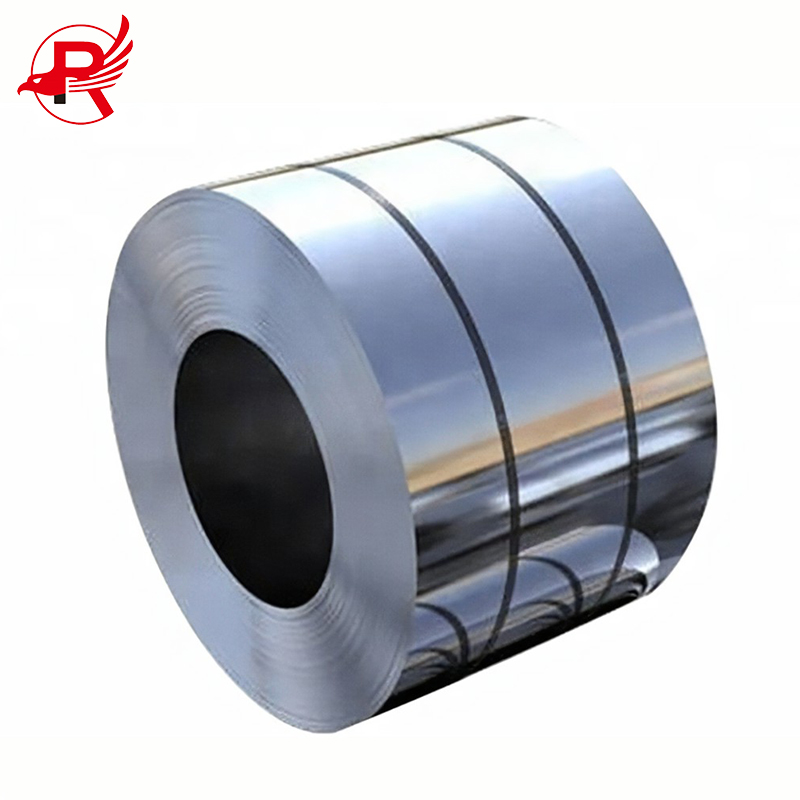

I-Aisi 1mm 2mm 3mm Cold Rolled 904 904L Stainless Steel Coil

| Igama lemveliso | Ikhoyili yentsimbi engagqwaliyo ye-904 904L |

| Ukuqina | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Umngxuma/Isigayo |

| Ukunyamezela Ubungakanani | ± 10% |

| Ububanzi bangaphakathi beCore yePhepha | Isiseko sephepha se-Ø500mm, isiseko esikhethekileyo sobubanzi bangaphakathi kwaye ngaphandle kwesiseko sephepha xa umthengi ecela |

| Umphezulu wokugqiba | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njl.njl. |

| Ukupakisha | Ipallet yomthi/Ityala lomthi |

| Immimiselo yokuhlawula | Idiphozithi ye-30% TT kunye nebhalansi ye-70% ngaphambi kokuthunyelwa, i-100% LC ibonwa |

| Ixesha lokuzisa | Iintsuku zokusebenza ezisi-7-15 |

| I-MOQ | 200Kgs |

| Izibuko lokuThumela | Izibuko laseShanghai/Ningbo |

| Isampulu | Isampulu yekhoyili yentsimbi engagqwali ye-904 904L iyafumaneka |

Intsimbi engenasici enekhabhoni ephantsi enika ukudityaniswa okuhle kakhulu, ukumelana nokugqwala okuhle kunye namandla aphezulu. Yinto efanelekileyo kwizicelo ezahlukeneyo kubandakanya izixhobo zokulungisa ukutya kunye nezixhobo zokulungisa iikhemikhali.

Olu luhlu lulandelayo lwezinye zezona zicelo zixhaphakileyo zeekhoyili zentsimbi engagqwaliyo ze-904 904L:

1. Izixhobo Zokucubungula Ukutya kunye Nezixhobo Zokucubungula Iikhemikhali

2. Amashishini eoyile negesi

3. Izicelo zaseLwandle

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Iinxalenye zeekhemikhali zekhoyili yentsimbi engagqwaliyo

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa iindlela ezahlukeneyo zokucubungula ukuqengqeleka okubandayo kunye nokuphinda kusetyenzwe umphezulu emva kokuqengqeleka, ukugqitywa komphezulu weekhoyili zentsimbi engagqwaliyo ezingama-904 904L kunokuba neentlobo ezahlukeneyo.

Ukucutshungulwa kweekhoyili zentsimbi engagqwali kubhekisa ekucutshungulweni nasekuphathweni komphezulu kweekhoyili zentsimbi engagqwali ukuhlangabezana neemfuno ezithile zokusetyenziswa. Iindlela eziqhelekileyo zokucubungula ziquka ukusika, ukupolisha, ukuzoba, njl. Ukusika kukusika ikhoyili yentsimbi engagqwali ngokobungakanani obufunekayo ngumthengi ukuze alungelelanise neziganeko ezahlukeneyo zemveliso. Ukupolisha kukusebenzisa iindlela zoomatshini okanye zeekhemikhali ukufezekisa isiphumo esikhanyayo kumphezulu weekhoyili zentsimbi engagqwali, ukuphucula ukuhombisa kwayo kunye nobuhle bayo. Ukubhrasha kukusebenzisa ukubhrasha ngoomatshini ukunika umphezulu weroli yentsimbi engagqwali ubume obuthile, ukwandisa ukumelana kwayo nokukrwela kunye nesiphumo sokuhombisa. Olu nyango lunokwenziwa ngokwezifiso ngokweemfuno ezithile zabathengi ukuqinisekisa ukuba ikhoyili yentsimbi engagqwali inokusebenza okufunekayo kunye nembonakalo kwindawo ethile yokusetyenziswa.

Inkqubo yokuvelisa i-coil yentsimbi engagqwaliyo yile: ukulungiswa kwezinto eziluhlaza - ukuqhoboshela kunye nokuqhoboshela - (ukuqhoboshela okuphakathi) - ukuqengqeleka - ukuqhoboshela okuphakathi - ukuqhoboshela - ukuqhoboshela - ukuqhoboshela - ukulinganisa (ukuqhoboshela nokupholisha imveliso egqityiweyo) - ukusika, ukupakishwa kunye nokugcinwa.

upakisho oluqhelekileyo lolwandle lwekhoyili yentsimbi engagqwaliyo ye-904 904L

Ukupakisha okuqhelekileyo kolwandle oluthunyelwa ngaphandle:

Iphepha elingangeni manzi eliyi-Winding + i-PVC Film + i-Strap Banding + i-Wooden Pallet okanye i-Wooden Case;

Ukupakisha okwenziwe ngokwezifiso ngokwesicelo sakho (Ilogo okanye ezinye izinto eziqulathweyo ziyavunywa ukuba ziprintwe kwiphakheji);

Ezinye izinto ezikhethekileyo zokupakisha ziya kuyilwa ngokwesicelo somthengi;

Iphakheji:

Ukupakishwa kweekhoyili zentsimbi engagqwali kubalulekile ukuqinisekisa ukhuseleko lwazo ngexesha lokuthuthwa. Inkqubo yokupakishwa kufuneka iqwalasele ubungakanani kunye nobunzima beekhoyili ukuqinisekisa ukuba zifika ngokukhuselekileyo kwindawo eziya kuyo. Nazi ezinye zeendlela eziqhelekileyo zokupakishwa kweekhoyili zentsimbi engagqwali:

1. Ibhokisi yomthi: Olu lolona hlobo lokupakisha olusetyenziswa kakhulu kwiikhoyili zentsimbi engagqwaliyo. Ibhokisi yomthi iqinisekisa ukuba iikhoyili zikhuselekile ekonakaleni okufana nokukrweleka okanye ukuqhekeka ngexesha lokuthuthwa. Zibonelela ngenkxaso egqwesileyo kwiikhoyili kwaye ziyamelana nokuphathwa nokufakwa okunzima.

2. Ukwaleka okukhuselekileyo: Ukwaleka okukhuselekileyo okufana nokupakishwa kweoyile, iphepha okanye iplastiki nako kunokubonelela ngomaleko owongezelelweyo wokhuseleko ngexesha lokuthunyelwa. Ukwaleka kukhusela umphezulu wekhoyili yentsimbi engatyiwayo kumswakama okanye ukungcola kwaye kuthintela umhlwa okanye ukugqwala.

3. Ukubopha: Bopha iikhoyili zentsimbi ngeebhanti zentsimbi okanye iibhanti zentsimbi ukuqinisekisa ukuba azishukumi ngexesha lokuthuthwa. Ukubopha kukwathintela ikhoyili ukuba yonakaliswe ziimpembelelo ezivela kweminye imithwalo.

uthutho:

Ukuthuthwa kweekhoyili zentsimbi engagqwali kubaluleke kakhulu njengokupakishwa kwazo. Iindlela ezifanelekileyo zokuphatha, ukulayisha, ukukhulula kunye nokuthumela ziyafuneka ukuqinisekisa ukuba iikhoyili azonakalanga okanye azibolile. Nazi ezinye zeendlela eziqhelekileyo zokuthumela iikhoyili zentsimbi engagqwali:

1. Ukulayisha nokukhulula: Xa ulayisha nokukhulula iikhoyili zentsimbi engagqwaliyo, kufuneka kuthathwe unonophelo ukuthintela umonakalo. Iikhoyili kufuneka zihlale ziphakanyiswa, ziphathwa kwaye zithuthwe kusetyenziswa izixhobo ezikhethekileyo ezifana neekhreyini okanye iifolokhwe.

2. Ukukhusela umthwalo: Umthwalo kufuneka uvalwe ngaphakathi kwitreyila okanye kwisikhongozeli ngexesha lokuthuthwa ukuze ungashukumi okanye ungashukumi. Iikhoyili kufuneka zilayishwe ngendlela yokuba ziqine kwaye zingangqubani.

3. Khetha inkampani yokuthutha impahla efanelekileyo: Kubalulekile nokukhetha inkampani yokuthutha impahla efanelekileyo. Inkampani yokuthutha impahla kufuneka ibe namava nolwazi lokuthutha iikhoyili zentsimbi engagqwaliyo. Kufuneka ibe nezixhobo ezifanelekileyo kunye nabasebenzi bokuphatha impahla ngokukhuselekileyo nangokufanelekileyo.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.