Khuphela iinkcukacha kunye nobukhulu be-Angle Steel yamva nje.

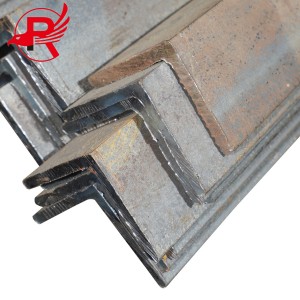

I-ASTM A36 Angle Steel | Iiprofayili zeZakhiwo zaseMelika zeZakhelo zeZakhiwo, iZakhiwo zeNkxaso, iiBridges kunye noKwakha izixhobo

| Igama lemveliso | Intsimbi ye-ASTM A36 Angle |

| Imigangatho | I-ASTM A36 / AISC |

| Uhlobo lwezinto | Intsimbi yoLwakhiwo lweKhabhoni ephantsi |

| Imilo | Intsimbi ye-Angle emile okwe-L |

| Ubude bemilenze (L) | 25 – 150 mm (1″ – 6″) |

| Ubukhulu (t) | 3 – 16 mm (0.12″ – 0.63″) |

| Ubude | 6 m / 12 m (ingenziwa ngokwezifiso) |

| Unikeze Amandla | ≥ 250 MPa |

| Tensile strength | 400 – 550 MPa |

| Isicelo | Izakhiwo zokwakha, ubunjineli beebhulorho, oomatshini nezixhobo, ishishini lezothutho, iziseko zophuhliso zikamasipala |

| Ixesha lokuzisa | Iintsuku ezisi-7-15 |

| Intlawulo | Ibhalansi ye-T/T30% Advance+70% |

Idatha yoBugcisa

Ulwakhiwo lweekhemikhali ze-ASTM A36 Angle Steel

| Ibanga lentsimbi | Ikhabhoni, ubuninzi,% | IManganese, % | iPhosphorus, ubuninzi,% | Isalfure, ubuninzi,% | I-silicon, % | |

| A36 | 0.26 | -- | 0.04 | 0.05 | ≤0.40 | |

| QAPHELA: Umxholo wobhedu uyafumaneka xa iodolo yakho ichaziwe. | ||||||

Ipropati yoMatshini ye-ASTM A36 Angle Steel

| Intsimbi Girade | Tensile strength, ksi[MPa] | Inqaku lemveliso elincinci, ksi[MPa] | Ukwandiswa kwi-8 in.[200] mm], ubuncinci,% | Ukwandiswa kwi-2 in.[50] mm], ubuncinci,% | |

| A36 | 58-80 [400-550] | 36[250] | 20.00 | 21 | |

Ubungakanani bentsimbi ye-ASTM A36 Angle Steel

| Ubude becala (mm) | Ubukhulu (mm) | Ubude (m) | Amanqaku |

| 25 × 25 | 3–5 | 6–12 | Intsimbi encinci, ekhaphukhaphu ye-engile |

| 30 × 30 | 3–6 | 6–12 | Ukusetyenziswa kwesakhiwo esilula |

| 40 × 40 | 4–6 | 6–12 | Izicelo ngokubanzi zesakhiwo |

| 50 × 50 | 4–8 | 6–12 | Ukusetyenziswa okuphakathi kwesakhiwo |

| 63 × 63 | 5–10 | 6–12 | Kwiibhulorho kunye neenkxaso zezakhiwo |

| 75 × 75 | 5–12 | 6–12 | Izicelo ezinzima zesakhiwo |

| 100 × 100 | 6–16 | 6–12 | Izakhiwo ezithwala imithwalo enzima |

Itheyibhile yokuthelekisa i-ASTM A36 Angle Steel Dimensions and Tolerances

| Imodeli (Ubungakanani be-Angle) | Umlenze A (mm) | Umlenze B (mm) | Ubukhulu t (mm) | Ubude L (m) | Ukunyamezela Ubude Bemilenze (mm) | Ukunyamezelana koButyebi (mm) | Ukunyamezelana kwe-Angle Squareness |

| 25×25×3–5 | 25 | 25 | 3–5 | 6/12 | ±2 | ± 0.5 | ≤ 3% yobude bomlenze |

| 30×30×3–6 | 30 | 30 | 3–6 | 6/12 | ±2 | ± 0.5 | ≤ 3% |

| 40×40×4–6 | 40 | 40 | 4–6 | 6/12 | ±2 | ± 0.5 | ≤ 3% |

| 50×50×4–8 | 50 | 50 | 4–8 | 6/12 | ±2 | ± 0.5 | ≤ 3% |

| 63×63×5–10 | 63 | 63 | 5–10 | 6/12 | ±3 | ± 0.5 | ≤ 3% |

| 75×75×5–12 | 75 | 75 | 5–12 | 6/12 | ±3 | ± 0.5 | ≤ 3% |

| 100×100×6–16 | 100 | 100 | 6–16 | 6/12 | ±3 | ± 0.5 | ≤ 3% |

Cofa iqhosha elisekunene

Umxholo owenziwe ngokwezifiso we-STM A36 Angle Steel

| Udidi Lokwenza Ngokwezifiso | Iinketho Ezifumanekayo | Inkcazo / Uluhlu | Ubungakanani obuncinci be-oda (MOQ) |

| Ukwenziwa ngokwezifiso kobukhulu | Ubungakanani bemilenze (A/B), Ubukhulu (t), Ubude (L) | Ubungakanani bomlenze: 25–150 mm; Ubukhulu: 3–16 mm; Ubude: 6–12 m (ubude obulungiselelwe wena buyafumaneka xa uceliwe) | iitoni ezingama-20 |

| Ukucwangcisa ngokwezifiso | Ukusika, Ukubhola, Ukufaka iiSlotting, Ukulungiselela ukuWelding | Imingxunya eyenziwe ngokwezifiso, imingxunya enemingxuma, ukusika i-bevel, ukusika i-mitre, kunye nokwenziwa kwezicelo zesakhiwo okanye zemizi-mveliso | iitoni ezingama-20 |

| Ukwenziwa ngokwezifiso koNyango lomphezulu | Umphezulu Omnyama, Upende/Ugqunywe nge-Epoxy, Ukutshisa nge-Hot-Dip Galvanizing | Ukugqitywa kokulwa nokugqwala ngokweemfuno zeprojekthi, ukuhlangabezana nemigangatho ye-ASTM A36 kunye ne-A123 | iitoni ezingama-20 |

| Ukumakisha kunye nokuPakisha ngokwezifiso | Ukumakisha Ngokwezifiso, Ukupakishwa Kwangaphandle | Iimpawu ziquka udidi, ubukhulu, inani lobushushu; ukubotshwa okulungele ukuthunyelwa ngaphandle ngeentambo zentsimbi, ukugquma, kunye nokukhuselwa kokufuma | iitoni ezingama-20 |

Ulwakhiwo lweZakhiwo

Isetyenziselwa ukwakha izakhelo, izixhaso, kunye nokuxhasa kwiiprojekthi zesakhiwo ngokubanzi.

Ukwenziwa kweNsimbi

Ilungele ukwenziwa kweefreyimu zoomatshini, izixhobo ezixhasayo, kunye neendibano zentsimbi ezidityanisiweyo.

Iiprojekthi zeShishini

Isetyenziswa kumaqonga, kwiindlela zokuhamba, kwizixhasi zemibhobho, kwiinkqubo zokuhambisa, nakwizakhiwo zokugcina izinto.

Ukusetyenziswa kweZiseko zoPhuhliso

Isetyenziswa kwiindawo zebhulorho, kwiindlela zokukhusela, nakwiindawo ezahlukeneyo zoluntu.

Ubunjineli Jikelele

Ifanelekile kwiibrakethi, iifreyimu, izixhobo, kunye nezixhobo zesinyithi ezenziwe ngokwezifiso kumsebenzi wokulungisa nokulungisa.

1) IOfisi yeSebe - inkxaso yabantu abathetha iSpanish, uncedo lokucoca impahla, njl.njl.

2) Ngaphezulu kweetoni ezingama-5,000 zesitokhwe esikhoyo, kunye nobukhulu obahlukeneyo

3) Ihlolwe yimibutho enegunya efana neCCIC, SGS, BV, kunye neTUV, kunye neepakethe ezisemgangathweni ezifanelekileyo elwandle

Ukhuseleko oluSisiseko: Ibhele nganye isongelwe nge-tarpaulin, kufakwa iipakethe ze-desiccant ezi-2-3 kwibhele nganye, emva koko ibhele igqunywe ngelaphu elingangeni manzi elivalwe ngobushushu.

Ukuhlanganisa: Intambo yentsimbi eyi-12-16mm Φ, iitoni ezi-2-3 ngebhanti yezixhobo zokuphakamisa kwizibuko laseMelika.

Ukulebhelisha ngokuhambelanaIilebhile zeelwimi ezimbini (isiNgesi + iSpanish) zisetyenziswa ngophawu olucacileyo lwezinto ezisetyenzisiweyo, iinkcukacha ezithile, ikhowudi ye-HS, ibhetshi kunye nenombolo yengxelo yovavanyo.

Intsebenziswano ezinzileyo neenkampani zokuhambisa imithwalo ezifana ne-MSK, i-MSC, i-COSCO, uthotho lweenkonzo zothutho olusebenzayo, kunye nothotho lweenkonzo zothutho olusebenzayo, siya kukwanelisa.

Silandela imigangatho yenkqubo yolawulo lomgangatho ye-ISO9001 kuzo zonke iinkqubo, kwaye sinolawulo oluqinileyo ukusuka ekuthengweni kwezinto zokupakisha ukuya ekucwangcisweni kweenkqubo zokuthutha izithuthi.

1. Zeziphi iisayizi ezikhoyo zee-engile ze-A36?

Ii-A36 Angle Bars ezithengiswayo zihlala zinobukhulu obuqala kwi-20×20mm ukuya kwi-200×200mm kububanzi obuqala kwi-3mm ukuya kwi-20mm. Ubukhulu obukhethekileyo bunokwenziwa ngokwezifiso ukuze buhambelane neemfuno zeprojekthi yakho.

2. Ngaba ndingazitshixa ii-ASTM A36 Angle Bars?

Ngokuqinisekileyo. Kukho iintlobo ngeentlobo ezahlukeneyo zolwelo lokuwelda kwaye izixhobo zingasetyenziswa kunye neebha ze-angle ze-A36 ezifana ne-TIG, i-MIG okanye i-arc welding.

3. Ndingayisebenzisa i-ASTM A36 kwimisebenzi yangaphandle?

Ewe, i-A36 bar ingasetyenziswa ngaphandle, nangona kunjalo unyango lomphezulu olufana nokupeyinta, ukuqinisa i-galvanizing okanye ukukhuselwa komhlwa luyafuneka ukuze lusetyenziswe ixesha elide.

4. Ngaba unemivalo ye-angle ye-A36 ekhazimlisiweyo?

Ewe. I-A36 Angle inokuba yi-hot dip galvanised okanye i-zinc coating ukuze inike ukhuselo oluhle kakhulu lokugqwala ukusetyenziswa ngaphandle okanye kwimizi-mveliso.

5. Ngaba kunokwenzeka ukusika okanye ukwenza ngokwezifiso ii-A36 Angle Bars?

Ngokuqinisekileyo. Sinikezela ngeenkonzo zokwenza ngokwezifiso kuquka ukusika ngobude, ukubhola, ukubhoboza kunye nezinye iinkonzo zokucubungula ngokusekelwe kwimizobo yakho okanye iinkcukacha zeprojekthi.

6. Ingakanani ubude obuqhelekileyo bebha ye-angle ye-ASTM A36?

Ubude obuqhelekileyo buyi-6m kunye ne-12m, kodwa ubude obulungiselelwe wena (umz. 8m okanye 10m) bunokwenziwa xa buceliwe ukuze buhambelane neemfuno zeprojekthi yakho.

7. Ndingazifumana na izatifikethi zovavanyo lwe-mill (MTC)?

Ewe, singazisa i-MTC ngokwe-EN 10204 3.1 okanye ngokwemfuno yakho ethile ukuqinisekisa ukulandeleka ngokupheleleyo kunye nokuqinisekiswa komgangatho.

Iinkcukacha zoqhakamshelo

Idilesi

Indawo yophuhliso lweshishini laseKangsheng,

Isithili saseWuqing, isixeko saseTianjin, eTshayina.

I-imeyile

Ifowuni

Amaxesha okusebenza

UMvulo-NgeCawa: Inkonzo yeeyure ezingama-24