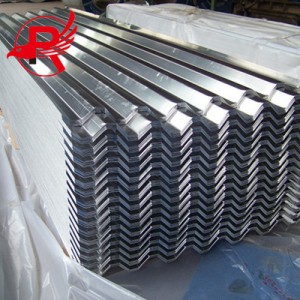

Ishiti yentsimbi eshushu eqinisiweyo ye-Astm A36 S335 3mm

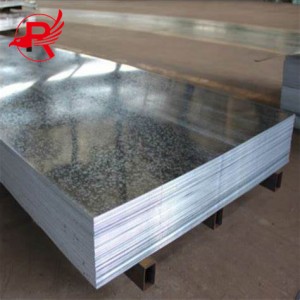

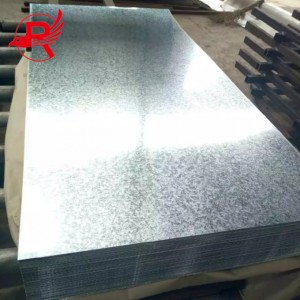

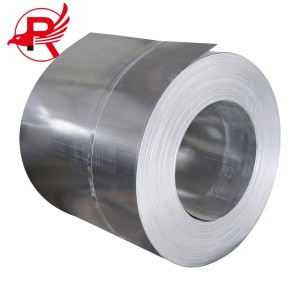

Ishidi lesinyithiIbhekisa kwishiti yentsimbi egqunywe ngomaleko we-zinc phezu komphezulu. I-Galvanizing yindlela yokuthintela umhlwa engabizi kakhulu nesebenzayo esetyenziswa rhoqo, kwaye malunga nesiqingatha semveliso ye-zinc ehlabathini isetyenziswa kule nkqubo.

Ngokweendlela zokuvelisa kunye nokucubungula, ingahlulwahlulwa ibe ziindidi ezilandelayo:

Ukuntywila okushushuIpleyiti yentsimbi egalelweyo. Nciphisa ipleyiti yesinyithi ebhityileyo kwi-zinc tank etyhidiweyo ukuze wenze ipleyiti yesinyithi ebhityileyo enomaleko we-zinc enamathele kumphezulu wayo. Okwangoku, inkqubo eqhubekayo yokwenza i-galvanizing isetyenziselwa kakhulu ukuvelisa, oko kukuthi, ipleyiti yesinyithi ebhityileyo iqhubeka intywiliselwa kwi-galvanizing tank ene-zinc etyhidiweyo ukwenza ipleyiti yesinyithi etyhidiweyo;

I-alloyedIphepha leNtsimbi elisegadiniOlu hlobo lwephaneli yentsimbi lwenziwa ngendlela yokuntywila eshushu, kodwa ifudunyezwa ibe malunga nama-500℃ emva nje kokuba iphumile etankini, ukuze yenze ifilimu ye-alloy ye-zinc kunye ne-iron. Eli phepha le-galvanized linamathele kakuhle kwipeyinti kwaye liyakwazi ukuwelda;

Ipleyiti yentsimbi egalelwe nge-electro-galvanized. Iphaneli yentsimbi egalelwe nge-electroplating inokulungiswa kakuhle. Nangona kunjalo, ulusu luncinci kwaye ukumelana nokugqwala kwalo akulunganga njengolu lweshiti zegalvini ezishushu

Amashiti e-galvanized aneempawu ezahlukeneyo ezenza ukuba asetyenziswe kakhulu kwiindawo ezahlukeneyo. Okokuqala, amashiti e-galvanized anokumelana nokugqwala okuhle kakhulu. Umaleko we-galvanized unokuthintela ngempumelelo umphezulu wentsimbi ukuba ungagqwali ngumoya, amanzi kunye nezinto zeekhemikhali, ngaloo ndlela wandise ubomi benkonzo yentsimbi. Okwesibini, amashiti e-galvanized anokumelana nokugqwala okuhle kwaye afanelekile kwiindawo ezifuna ukumelana nokungqubana nokugqwala, njengezakhiwo zokwakha, izixhobo zoomatshini kunye nezinye iindawo. Ukongeza, amashiti e-galvanized nawo aneempawu ezilungileyo zokucubungula kwaye anokucutshungulwa ngokugoba, ukunyathela, ukuwelda, njl.njl., kwaye afanelekile ukuvelisa iimilo ezahlukeneyo ezintsonkothileyo. Ukongeza, umphezulu wamashiti e-galvanized uthambile kwaye muhle, kwaye ungasetyenziswa ngokuthe ngqo njengezinto zokuhombisa. Ukongeza, amashiti e-galvanized nawo anokuqhuba kakuhle kombane kwaye afanelekile kumandla ombane, unxibelelwano kunye nezinye iindawo. Ngokubanzi, amashiti e-galvanized abe yenye yezinto ezibalulekileyo ekwakheni, koomatshini, kumbane, kunxibelelwano nakwezinye iindawo ngenxa yokumelana nokugqwala kwawo, ukumelana nokugqwala kunye nokusebenza kakuhle kokucubungula.

Njengesixhobo esinokumelana nokugqwala okugqwesileyo, iphepha le-galvanized lisetyenziswa kakhulu kwiindawo ezahlukeneyo.

Okokuqala, kwicandelo lokwakha,Ipleyiti yentsimbi eshushu egalelweyoZisetyenziswa rhoqo kwiinkqubo zokuxhasa kunye nokukhupha amanzi kwizakhiwo zezakhiwo. Zingasetyenziswa kwizakhelo zokwakha, ii-handrails zezitebhisi, ii-railings kunye nezinye izinto, kwaye zingasetyenziswa njengezinto eziphambili zemibhobho yokukhupha amanzi kuba ukumelana kwayo nokugqwala kunokwandisa ubomi bayo benkonzo.

Okwesibini, kwicandelo lemizi-mveliso, amaphepha e-galvanized adla ngokusetyenziswa ukwenza izixhobo ezahlukeneyo kunye nezinto ezinje ngeetanki zokugcina, iipayipi, iifeni, izixhobo zokuhambisa, njl. Ukumelana nokugqwala kwamaphepha e-galvanized kwenza ukuba asetyenziswe ixesha elide kwiindawo zoshishino ezinzima, okuqinisekisa ukusebenza ngokukhuselekileyo kwezixhobo.

Ukongeza, kwicandelo lezolimo, amaphepha e-galvanized nawo anezicelo ezibalulekileyo. Angasetyenziswa kwiinkqubo zokunkcenkceshela iifama, izakhiwo zokuxhasa oomatshini bezolimo, njl. kuba ukumelana kwawo nokugqwala kunokumelana nokukhukuliseka kwezixhobo ziikhemikhali emhlabeni.

Ukongeza, kwicandelo lezothutho, amaphepha e-galvanized asetyenziswa rhoqo ekwenzeni iinxalenye zeemoto, izinto zeenqanawa, njl.njl., kuba ukumelana nokugqwala kwazo kunokwandisa ubomi benkonzo yezithuthi zothutho.

Ngokubanzi, amaphepha e-galvanized anezicelo ezibalulekileyo kulwakhiwo, kushishino, kwezolimo, kwezothutho nakwezinye iindawo, kwaye ukumelana kwawo nokugqwala kuwenza abe yenye yezona zinto zifanelekileyo kwizixhobo ezahlukeneyo kunye nezakhiwo.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.