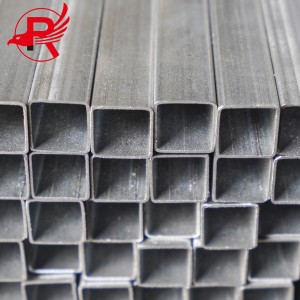

Ityhubhu yentsimbi ekhazimlisiweyo ye-Astm Standard St37 Hollow Tube Square 2.5 intshi

Umbhobho wesikwere ogqunyiweyo, eyaziwa ngokuba yipayipi yentsimbi egalelweyo, yahlulwe yaba yi-hot dip galvanized kunye ne-electric galvanized ezimbini, i-hot dip galvanized galvanized layer etyebileyo, ene-coating efanayo, i-adhesion enamandla, ubomi benkonzo ende kunye nezinye izibonelelo. Ixabiso le-electrogalvanizing liphantsi, umphezulu awugudi kakhulu, kwaye ukumelana kwayo nokugqwala kubi kakhulu kuneepayipi ze-hot-dip galvanized.

Umbhobho ogqunyiweyo obandayo: umbhobho ogqunyiweyo ogqunyiweyo obandayo ugqunyiwe ngombane, ubungakanani be-galvanized buncinci kakhulu, yi-10-50 grams kuphela ngemitha yesikwere, ukumelana kwayo nokugqwala kwahlukile kakhulu kumbhobho ogqunyiweyo oshushu. Izityalo zemveliso yemibhobho eqhelekileyo egqunyiweyo, ngokomgangatho, uninzi alusebenzisi i-electron galvanizing (cold plating). Kuphela ngamashishini amancinci anezixhobo eziphelelwe lixesha asebenzisa i-electron galvanizing, ewe, ixabiso liphantsi kakhulu.

Umbhobho we-galvanized oshushu

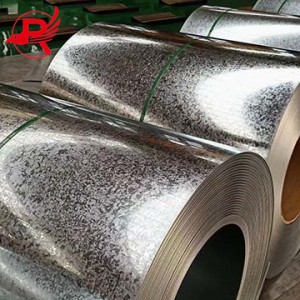

Isinyithi esinyibilikisiweyo sidibana ne-matrix yesinyithi ukuze sivelise umaleko we-alloy, ukuze i-matrix kunye ne-coating zidityaniswe. I-Hot dip galvanizing kukuqala ngokucola umbhobho wesinyithi, ukuze kususwe i-iron oxide kumphezulu wombhobho wesinyithi, emva kokucola, ngesisombululo samanzi se-ammonium chloride okanye i-zinc chloride okanye itanki yesisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride ukuze kucocwe, kuze kufakwe kwi-hot dip plating tank. I-Hot dip galvanizing ineengenelo zokucola okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende. Uninzi lweenkqubo ezikumntla zisebenzisa inkqubo yokuzalisa i-zinc yombhobho we-coil webhanti ekhatyulweyo.

Umbhobho obandayo ogqunyiweyo

I-cold galvaning ifakwa ngombane, ubungakanani be-galvaning buncinci kakhulu, yi-10-50g/m2 kuphela, ukumelana kwayo nokugqwala kwahlukile kakhulu kune-hot galvaning pipe. Abavelisi beepayipi ze-galvaning eziqhelekileyo, ukuqinisekisa umgangatho, uninzi alusebenzisi i-electric galvanizing (cold plating). Kuphela ngamashishini amancinci anezixhobo eziphelelwe lixesha asebenzisa i-electric galvanizing, ewe, amaxabiso awo aphantsi kakhulu. Kwixesha elizayo, iipayipi ze-cold galvaning azivumelekanga ukusetyenziswa njengeepayipi zamanzi negesi.

Umbhobho wentsimbi egqunywe ngesinyithi esishushu

Iimpendulo ezintsonkothileyo zomzimba nezeekhemikhali zenzeka phakathi kwe-substrate yetyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-alloy ye-zinc-iron eqinileyo enokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yepayipi yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

Emva kokuphuhliswa kombhobho wentsimbi eshushu eyenziwe nge-galvanized ngeminyaka yoo-1960 ukuya kowe-1970, umgangatho wemveliso uphuculwe kakhulu, ukususela ngo-1981 ukuya kowe-1989 yanikwa iSebe leMicimbi yezeMetallurgical yeemveliso ezikumgangatho ophezulu kunye nebhaso lesizwe lesilivere, imveliso nayo yanda kangangeminyaka emininzi, ukususela ngo-1993 imveliso engaphezulu kweetoni ezingama-400,000, ukususela ngo-1999 imveliso engaphezulu kweetoni ezingama-600,000, yaze yathunyelwa kuMzantsi-mpuma Asia, eAfrika, eMelika, eJapan, eJamani kumazwe nakwiindawo. Imibhobho ye-galvanized eshushu isetyenziswa kakhulu njengemibhobho yamanzi kunye nemibhobho yegesi, kwaye iinkcukacha eziqhelekileyo ziyi +12.5 ~ + 102 mm. Emva kweminyaka yoo-1990, ngenxa yokuba urhulumente wayegxile ekukhuseleni okusingqongileyo, ulawulo lwamashishini angcolisekileyo kakhulu luya lusiba ngqongqo ngakumbi, "inkunkuma emithathu" eveliswa ekuvelisweni kwemibhobho eshushu ediphiniweyo kunzima ukuyisombulula, kunye nophuhliso olukhawulezayo lwemibhobho edibeneyo yentsimbi engagqwaliyo, imibhobho yePVC kunye nemibhobho edibeneyo, kunye norhulumente ukukhuthaza ukusetyenziswa kwezixhobo zokwakha iikhemikhali, ukusetyenziswa kwemibhobho yentsimbi ediphiniweyo kuthintelwe, okwenza uphuhliso lwemibhobho edibeneyo eshushu ediphiniweyo luye lwachaphazeleka kakhulu. Umqadi kunye nomda, umbhobho odibeneyo oshushu odiphiniweyo kamva waphuhliswa kancinci.

Umbhobho wentsimbi ebandayo egalelweyo

Umaleko we-zinc ngumgqumo wombane, kwaye umaleko we-zinc ubekwe ngokwahlukeneyo nge-matrix yepayipi yentsimbi. Umaleko we-zinc ubhityile, kwaye umaleko we-zinc unamathele nje kwi-matrix yetyhubhu yentsimbi kwaye kulula ukuwa. Ngenxa yoko, ukumelana kwawo nokugqwala kuphantsi. Kwizakhiwo ezintsha zokuhlala, akuvumelekanga ukusebenzisa imibhobho yentsimbi ebandayo njengemibhobho yokuhambisa amanzi.

Isicelo

Ngenxa yokuba umbhobho wesikwere ogqunyiweyo ugqunyiwe kumbhobho wesikwere, ngoko ke uluhlu lokusetyenziswa kombhobho wesikwere ogqunyiweyo lwandisiwe kakhulu kunombhobho wesikwere. Usetyenziswa kakhulu eludongeni lwekhethini, ulwakhiwo, ukwenziwa koomatshini, iiprojekthi zokwakha intsimbi, ukwakhiwa kweenqanawa, isibiyeli sokuvelisa umbane welanga, ubunjineli besakhiwo sentsimbi, ubunjineli bamandla, isikhululo samandla, ezolimo kunye noomatshini beekhemikhali, udonga lwekhethini yeglasi, itshasi yeemoto, isikhululo seenqwelo-moya njalo njalo.

| Igama lemveliso | Umbhobho weNtsimbi yesikwere ogalelweyo | |||

| Ukwaleka kweZinc | 35μm-200μm | |||

| Ubukhulu bodonga | 1-5MM | |||

| Umphezulu | I-galvanized esele igqityiwe, I-galvanized eshushu edityiweyo, I-electro galvanized, Imnyama, Ipeyintiwe, Ifakwe imisonto, Iqoshwe, Isokhethi. | |||

| Ibanga | Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.BD | |||

| Ukunyamezelana | ±1% | |||

| Ioyile okanye Ayinaoyile | Ayinawoyela | |||

| Ixesha lokuzisa | Iintsuku ezi-3-15 (ngokweetoni zokwenyani) | |||

| Ukusetyenziswa | Ubunjineli bokwakha, uyilo lwezakhiwo, iinqaba zentsimbi, indawo yokuthutha iinqanawa, iiscaffolding, iistruts, iinqwaba zokuthintela ukudilika komhlaba kunye nezinye izinto izakhiwo | |||

| Iphakheji | Zifakwe kwiipakethe ezinemicu yentsimbi okanye kwiipakethe zelaphu ezikhululekileyo, ezingalukwanga okanye ngokwesicelo sabathengi | |||

| I-MOQ | Itoni e-1 | |||

| Ixesha lokuhlawula | T/T | |||

| Ixesha loRhwebo | I-FOB, i-CFR, i-CIF, i-DDP, i-EXW | |||

Iinkcukacha

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.