Ixabiso Elihle ASTM A312 304 304L 316LS Umbhobho weNsimbi engenasici

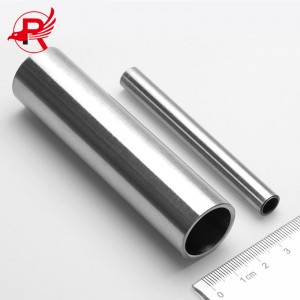

| Igama lemveliso | Ipayipi engqukuva yentsimbi engenasici |

| Umgangatho | I-ASTM AISI DIN, EN, GB, JIS |

| Ibanga lentsimbi

| Uthotho lwama-200: 201,202 |

| Uthotho lwe-300: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| Uthotho lwe-400: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Intsimbi yeDuplex: 904L, 2205, 2507, 2101, 2520, 2304 | |

| Ububanzi obungaphandle | 6-2500mm (njengoko kufuneka) |

| Ubukhulu | 0.3mm-150mm (njengoko kufuneka) |

| Ubude | 2000mm/2500mm/3000mm/6000mm/12000mm (njengoko kufuneka) |

| Ubuchule | Akukho mthungo |

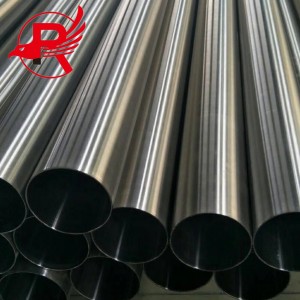

| Umphezulu | Inombolo 1 2B BA 6K 8K Isipili Inombolo 4 HL |

| Ukunyamezelana | ±1% |

| Imigaqo yeXabiso | I-FOB, i-CFR, i-CIF |

Umbhobho wentsimbi engagqwaliyo luhlobo lwentsimbi ende engqukuva engenanto, esetyenziswa kakhulu kwiipayipi zothutho lwemizi-mveliso ezifana nepetroleum, imboni yeekhemikhali, unyango lwezonyango, ukutya, imboni yokukhanya, izixhobo zoomatshini, njl.njl., kunye nezixhobo zesakhiwo soomatshini. Ukongeza, xa amandla okugoba kunye nokujika kwemithambo efana, ubunzima bulula, ngoko ke ikwasetyenziswa kakhulu ekwenziweni kweendawo zoomatshini kunye nezakhiwo zobunjineli. Ikwasetyenziswa njengefenitshala kunye nezixhobo zasekhitshini, njl.njl.

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Iinxalenye zeekhemikhali zePipe yentsimbi engagqwaliyo

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa iindlela ezahlukeneyo zokucubungula ukuqengqeleka okubandayo kunye nokuphinda kusetyenzwe umphezulu emva kokuqengqeleka, ukugqitywa komphezulu wentsimbi engagqwaliyoibhaii-s zinokuba neentlobo ezahlukeneyo.

Ukulungiswa komphezulu wombhobho wentsimbi engagqwaliyo kune-NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright kunye nezinye izinto ezigqityiweyo kumphezulu, njl.

NO.1: Umphezulu weNombolo 1 ubhekisa kumphezulu ofunyenwe ngonyango lobushushu kunye nokugalela emva kokugalela ngobushushu kombhobho wentsimbi engagqwaliyo. Kukususa isikali se-oxide emnyama esiveliswa ngexesha lokugalela ngobushushu kunye nonyango lobushushu ngokugalela okanye iindlela ezifanayo zonyango. Olu lulungiso lomphezulu weNombolo 1. Umphezulu weNombolo 1 umhlophe oluhlaza okwesibhakabhaka kwaye u-matt. Usetyenziswa kakhulu kumashishini angatshiyo nokumelana nokugqwala angadingi ukukhazimla komphezulu, njengeshishini lotywala, ishishini leekhemikhali kunye nezikhongozeli ezinkulu.

2B: Umphezulu we-2B wahlukile kumphezulu we-2D kuba uthanjiswe nge-roller egudileyo, ngoko ke ukhanya ngakumbi kunomphezulu we-2D. Uburhabaxa bomphezulu Ixabiso le-Ra elilinganiswa sisixhobo yi-0.1 ~ 0.5μm, olu lolona hlobo luqhelekileyo lokucubungula. Olu hlobo lomphezulu wentsimbi engagqwaliyo lolona luguquguqukayo, lufanelekile kwiinjongo eziqhelekileyo, olusetyenziswa kakhulu kumashishini eekhemikhali, ephepha, epetroleum, ezonyango nakwamanye amashishini, kwaye lungasetyenziswa njengodonga lwekhethini yesakhiwo.

Ukugqitywa Okuqinileyo kwe-TR: Intsimbi engagqwaliyo ye-TR ikwabizwa ngokuba yintsimbi eqinileyo. Amanqanaba ayo entsimbi angama-304 kunye nama-301, asetyenziselwa iimveliso ezifuna amandla aphezulu kunye nobunzima, njengezithuthi zikaloliwe, iibhanti zokuhambisa, izipringi kunye neegasket. Umgaqo kukusebenzisa iimpawu zokuqina komsebenzi zentsimbi engagqwaliyo ye-austenitic ukwandisa amandla kunye nobunzima bepleyiti yentsimbi ngeendlela zokusebenza ezibandayo ezifana nokuqengqeleka. Izinto eziqinileyo zisebenzisa iipesenti ezimbalwa ukuya kumashumi ambalwa eepesenti zokuqengqeleka okuthambileyo ukuze kuthathelwe indawo ukuthamba okuthambileyo komphezulu wesiseko se-2B, kwaye akukho kuqhoboshelwa okwenziwayo emva kokuqengqeleka. Ke ngoko, umphezulu oqinileyo we-TR wezinto eziqinileyo ngumphezulu oqengqelekayo emva kokuqhaqheka okubandayo.

I-Rerolled Bright 2H: Emva kwenkqubo yokuqengqeleka, umbhobho wentsimbi engagqwali uza kucutshungulwa i-bright annealing. Umbhobho ungapholiswa ngokukhawuleza ngumgca we-continuous annealing. Isantya sokuhamba kombhobho wentsimbi engagqwali kumgca simalunga ne-60m ~ 80m/min. Emva kweli nyathelo, umphezulu uza kuqengqeleka kwakhona nge-2H.

Inombolo 4: Umphezulu weNombolo 4 ngumphezulu ocoliweyo ocwebezelayo okhanyayo kunomphezulu weNombolo 3. Ukwafunyanwa ngokupolisha umbhobho wentsimbi engagqwaliyo eqhotsiweyo yentsimbi engagqwaliyo enomphezulu we-2 D okanye we-2 B njengesiseko kwaye upolise ngebhanti erhabaxa enobukhulu beenkozo ze-150-180# Umphezulu ochwetheziweyo. Uburhabaxa bomphezulu Ixabiso le-Ra elilinganiswa sisixhobo yi-0.2 ~1.5μm. Umphezulu we-NO.4 usetyenziswa kakhulu kwizixhobo zokutyela nekhitshi, izixhobo zonyango, imihombiso yezakhiwo, izikhongozeli, njl.njl.

I-HL: Umphezulu we-HL udla ngokubizwa ngokuba yi-hairline finish. Umgangatho we-JIS waseJapan uthi ibhanti ye-abrasive eyi-150-240# isetyenziselwa ukupolisha umphezulu we-abrasive oqhubekayo ofana nomgca weenwele ofunyenweyo. Kwimigangatho ye-GB3280 yaseTshayina, le migaqo ayicacanga kangako. Umgangatho we-HL usetyenziswa kakhulu ekuhombiseni izakhiwo ezifana nee-elevator, ii-escalators, kunye nee-facade.

Inombolo 6: Umphezulu weNombolo 6 usekwe kumphezulu weNombolo 4 kwaye upholishwa ngakumbi ngebrashi yeTampico okanye izinto ezirhabaxa ezinobukhulu besuntswana ye-W63 echazwe ngumgangatho we-GB2477. Lo mphezulu unokukhanya okuhle kwesinyithi kunye nokusebenza okuthambileyo. Ukukhanya kubuthathaka kwaye akubonisi mfanekiso. Ngenxa yale propati ilungileyo, ifanelekile kakhulu ekwenzeni iindonga zamakhethini ezakhiwo kunye nemihombiso yemiphetho yezakhiwo, kwaye ikwasetyenziswa kakhulu njengezixhobo zasekhitshini.

I-BA: I-BA ngumphezulu ofunyenwe ngonyango lobushushu olukhanyayo emva kokuqengqeleka okubandayo. Unyango lobushushu olukhanyayo lugquma phantsi komoya okhuselayo oqinisekisa ukuba umphezulu awungcoliswanga ukuze kugcinwe ukukhanya komphezulu oqengqeleka okubandayo, uze usebenzise i-roll ethambileyo echanekileyo yokulinganisa ukukhanya ukuphucula ukukhanya komphezulu. Lo mphezulu usondele kwisiphelo sesipili, kwaye uburhabaxa bomphezulu Ixabiso le-Ra elilinganiswa sisixhobo yi-0.05-0.1μm. Umphezulu we-BA unoluhlu olubanzi lokusetyenziswa kwaye ungasetyenziswa njengezixhobo zasekhitshini, izixhobo zasekhaya, izixhobo zonyango, iinxalenye zeemoto kunye nemihombiso.

Inombolo 8: Inombolo 8 ngumphezulu ogqityiweyo kwisibuko onokukhanya okuphezulu ngaphandle kweenkozo ezirhabaxa. Ishishini lokucubungula intsimbi engagqwaliyo likwabiza iipleyiti ze-8K. Ngokubanzi, izinto ze-BA zisetyenziswa njengezinto eziluhlaza zokugqiba isibuko kuphela ngokusila nokupolisha. Emva kokugqiba isibuko, umphezulu ungowobugcisa, ngoko ke usetyenziswa kakhulu ekuhombiseni umnyango wesakhiwo kunye nokuhombisa ngaphakathi.

Inkqubo ephambili yemveliso: intsimbi engqukuva → ukuhlolwa kwakhona → ukuxobuka → ukugquma → ukubethelela → ukufudumeza → ukugqobhoza → intloko ethe tyaba → ukuhlolwa nokusila → ukuqengqeleka okubandayo (umzobo obandayo) → ukususa amafutha → unyango lobushushu → ukulula → ukusika umbhobho (okumiselweyo ubude) ) → ukuphola/ukudlulisa amanzi → ukuhlolwa kwemveliso egqityiweyo (umbane we-eddy, i-ultrasonic, uxinzelelo lwamanzi) → ukupakishwa kunye nokugcinwa.

1. Ukusika intsimbi engqukuva: Emva kokufumana intsimbi engqukuva kwindawo yokugcina izinto eziluhlaza, bala ubude bokusika bentsimbi engqukuva ngokweemfuno zenkqubo, uze uzobe umgca kwintsimbi engqukuva. Iintsimbi zibekwe ngokwemigangatho yentsimbi, amanani obushushu, amanani ebhetshi yemveliso kunye neenkcukacha, kwaye iziphelo zahlulwe ngeepeyinti zemibala eyahlukeneyo.

2. Ukubeka embindini: Xa ubeka embindini umatshini wokubhola iingalo ezinqamlezileyo, qala ufumane indawo ephakathi kwicandelo lentsimbi engqukuva, ukhuphe umngxuma wesampulu, uze uwulungise ngokuthe nkqo kwitafile yomatshini wokubhola ukuze ubekwe embindini. Iibhari ezingqukuva emva kokubeka embindini zibekwe ngokwenqanaba lentsimbi, inombolo yobushushu, iinkcukacha kunye nenombolo yebhetshi yemveliso.

3. Ukuxobula: ukuxobula kwenziwa emva kokuhlolwa kwezinto ezingenayo. Ukuxobula kuquka ukuxobula nge-lathe kunye nokusika nge-windmill. Ukuxobula nge-lathe kwenziwa kwi-lathe ngendlela yokucubungula nge-clamp enye kunye ne-top enye, kwaye ukusika nge-windmill kukuxhoma intsimbi engqukuva kwisixhobo somatshini. Yenza i-whirling.

4. Ukuhlolwa komphezulu: Ukuhlolwa komgangatho wentsimbi engqukuva exotyulweyo kuyenziwa, kwaye iziphene zomphezulu ezikhoyo ziyaphawulwa, kwaye abasebenzi bokugaya baya kuzigaya de zifaneleke. Iibhari ezingqukuva eziphumelele uhlolo ziqokelelwa ngokwahlukeneyo ngokwenqanaba lentsimbi, inombolo yobushushu, iinkcukacha kunye nenombolo yebhetshi yemveliso.

5. Ukufudumeza ngentsimbi engqukuva: Izixhobo zokufudumeza ngentsimbi engqukuva ziquka isithando somlilo esifakwe igesi kunye nesithando somlilo esifakwe igesi. Isithando somlilo esifakwe igesi sisetyenziselwa ukufudumeza kwiibhetshi ezinkulu, kwaye isithando somlilo esifakwe igesi sisetyenziselwa ukufudumeza kwiibhetshi ezincinci. Xa ungena kwisithando somlilo, iibhetshi ezingqukuva zeentlobo ezahlukeneyo zentsimbi, amanani obushushu kunye neenkcukacha zahlulwe yifilimu yangaphandle endala. Xa iibhetshi ezingqukuva zifudunyezwa, ii-turners zisebenzisa izixhobo ezikhethekileyo ukujika iibhetshi ukuqinisekisa ukuba iibhetshi ezingqukuva zifudunyezwa ngokulinganayo.

6. Ukubhoboza okujijekileyo okushushu: sebenzisa iyunithi yokubhoboza kunye necompressor yomoya. Ngokweenkcazo zentsimbi ejikelezileyo enezimbobo, kukhethwa iipleyiti zesikhokelo ezifanelekileyo kunye neeplagi ze-molybdenum, kwaye intsimbi ejikelezileyo eshushu ibhobozwa nge-perforator, kwaye imibhobho yenkunkuma ebhoboziweyo ifakwa ngokungacwangciswanga edamini ukuze iphole ngokupheleleyo.

7. Ukuhlolwa nokusila: Jonga ukuba umphezulu wangaphakathi nowangaphandle wombhobho wenkunkuma uthambile kwaye uthambile, kwaye akufuneki kubekho ulusu lweentyatyambo, imifantu, iileya ezidibeneyo, imingxunya enzulu, iimpawu zemisonto ezinzulu, intsimbi yetower, iifritters, iiBaotou kunye neentloko zesikele. Iziphene zomphezulu wombhobho wenkunkuma zinokususwa ngendlela yokusila yasekuhlaleni. Iipayipi zenkunkuma eziphumelele uhlolo okanye ezo ziphumelele uhlolo emva kokulungiswa nokusila ezineziphene ezincinci ziya kudityaniswa zii-bundlers zeworkshop ngokweemfuno, kwaye zibekwe ngokwenqanaba lentsimbi, inombolo yesithando somlilo, iinkcukacha kunye nenani lebhetshi yokuvelisa yombhobho wenkunkuma.

8. Ukulungisa: Imibhobho yenkunkuma engenayo kwindawo yokusebenzela egqobhozayo ipakishwe ngamaqoqo. Imilo yombhobho wenkunkuma engenayo igobile kwaye kufuneka ilungiswe. Izixhobo zokulungisa zingumatshini wokulungisa ngokuthe nkqo, umatshini wokulungisa ngokuthe nkqo kunye nomatshini we-hydraulic press othe nkqo (osetyenziselwa ukulungisa kwangaphambili xa umbhobho wentsimbi unomphetho omkhulu). Ukuze kuthintelwe umbhobho wentsimbi ukuba ungatsibi ngexesha lokulungisa, kusetyenziswa isikhongozeli se-nylon ukunciphisa umbhobho wentsimbi.

9. Ukusikwa kwemibhobho: Ngokwesicwangciso semveliso, umbhobho wenkunkuma othe tye kufuneka unqunyulwe intloko nomsila, kwaye izixhobo ezisetyenziswayo ngumatshini wokusika amavili okugaya.

10. Ukugalela: Umbhobho wentsimbi othe tye kufuneka ugaleleke ukuze kususwe isikali se-oxide kunye nokungcola okuphezu kombhobho wenkunkuma. Umbhobho wentsimbi ugaleleke kwindawo yokusebenzela yokugalela, kwaye umbhobho wentsimbi uphakanyiswa kancinci kancinci ungene kwitanki yokugalela ukuze ugaleleke ngokuqhuba.

11. Ukusila, ukuhlolwa kwe-endoscopy kunye nokupolisha ngaphakathi: imibhobho yentsimbi efanelekileyo yokugaya ingena kwinkqubo yokusila yangaphandle, imibhobho yentsimbi epholisiweyo ijongwa nge-endoscopic, kwaye iimveliso okanye iinkqubo ezingafanelekanga ezineemfuno ezikhethekileyo kufuneka zipoliselwe ngaphakathi.

12. Inkqubo yokuqengqeleka ebandayo/inkqubo yokuzoba ebandayo

Ukuqengqeleka okubandayo: Umbhobho wentsimbi uqengqeleka ngeeroli zomatshini wokuqengqeleka obandayo, kwaye ubukhulu kunye nobude bombhobho wentsimbi butshintshwa kukuguquka okubandayo okuqhubekayo.

Umzobo obandayo: Umbhobho wentsimbi uyavutha kwaye uncitshiswa eludongeni ngomatshini wokudweba obandayo ngaphandle kokufudumeza ukutshintsha ubungakanani kunye nobude bombhobho wentsimbi. Umbhobho wentsimbi otsalwa ebandayo unobuchane obuphezulu kunye nokugqitywa okuhle komphezulu. Ingxaki kukuba uxinzelelo oluseleyo lukhulu, kwaye imibhobho emikhulu etsalwa ebandayo isetyenziswa rhoqo, kwaye isantya sokwenza imveliso egqityiweyo sicotha. Inkqubo ethile yokudweba ebandayo ibandakanya:

① Intloko yokuwelda yentloko: Ngaphambi kokuba kutsalwe ngokubandayo, kufuneka kufakwe isiphelo esinye sombhobho wentsimbi (umbhobho wentsimbi omncinci) okanye intloko yokuwelda (umbhobho wentsimbi omkhulu) ukulungiselela inkqubo yokudweba, kwaye kufuneka kufudunyezwe umbhobho wentsimbi okhethekileyo uze utsalwe.

② Ukuthambisa nokubhaka: Ngaphambi kokuba umbhobho wentsimbi utsalwe ngokubandayo emva kwentloko (intloko yokuwelda), umngxuma wangaphakathi kunye nomphezulu wangaphandle wombhobho wentsimbi kufuneka uthanjiswe, kwaye umbhobho wentsimbi ogqunywe nge-lubricant womiswe ngaphambi kokuba utsalwe ngokubandayo.

③ Umzobo obandayo: Umbhobho wentsimbi emva kokuba i-lubricant yomile ungena kwinkqubo yokuzoba ebandayo, kwaye izixhobo ezisetyenziselwa ukuzoba ebandayo ngumatshini wokuzoba obandayo wetyathanga kunye nomatshini wokuzoba obandayo we-hydraulic.

13. Ukususa amafutha: Injongo yokususa amafutha kukususa ioyile eqengqelekayo enamathele eludongeni lwangaphakathi nangaphandle kombhobho wentsimbi emva kokuyiqengqa ngokuyihlamba, ukuze kuthintelwe ukungcolisa umphezulu wentsimbi ngexesha lokuyigquma nokuthintela ukwanda kwekhabhoni.

14. Unyango lobushushu: Unyango lobushushu lubuyisela imo yezinto ngokusebenzisa i-recrystallization kwaye lunciphisa ukumelana nokuguqulwa kwesinyithi. Izixhobo zonyango lobushushu sisithando sonyango lobushushu sesisombululo segesi yendalo.

15. Ukucolwa kweemveliso ezigqityiweyo: Iipayipi zentsimbi emva kokusikwa zifakwa ekucolweni okugqityiweyo ngenjongo yokungashukumi komphezulu, ukuze kwenziwe ifilimu ekhusela i-oxide kumphezulu weepayipi zentsimbi kwaye kuphuculwe ukusebenza kakuhle kweepayipi zentsimbi.

16. Ukuhlolwa kwemveliso egqityiweyo: Inkqubo ephambili yokuhlolwa kwemveliso egqityiweyo kunye novavanyo kukuhlolwa kwemitha → i-eddy probe → i-super probe → uxinzelelo lwamanzi → uxinzelelo lomoya. Ukuhlolwa komphezulu ikakhulu kukujonga ngesandla ukuba kukho iziphene kumphezulu wombhobho wentsimbi, nokuba ubude bombhobho wentsimbi kunye nobukhulu bodonga lwangaphandle ziyafaneleka na; ukufunyanwa kwe-eddy kusebenzisa ikakhulu i-eddy current flaw detector ukujonga ukuba kukho iingozi kumbhobho wentsimbi; ukufunyanwa okuphezulu kusebenzisa ikakhulu i-ultrasonic flaw detector ukujonga ukuba umbhobho wentsimbi uqhekekile ngaphakathi okanye ngaphandle; uxinzelelo lwamanzi, uxinzelelo lomoya kukusebenzisa umatshini we-hydraulic kunye nomatshini woxinzelelo lomoya ukubona ukuba umbhobho wentsimbi uvuza amanzi okanye umoya, ukuqinisekisa ukuba umbhobho wentsimbi ukwimeko elungileyo.

17. Ukupakisha kunye nokugcina impahla: Iipayipi zentsimbi eziphumelele uhlolo zingena kwindawo yokupakisha imveliso egqityiweyo ukuze zipakishwe. Izinto ezisetyenziselwa ukupakisha ziquka izivatho zemingxuma, iingxowa zeplastiki, ilaphu lesikhumba senyoka, iibhodi zomthi, iibhanti zentsimbi engatyiwayo, njl. Umphezulu wangaphandle wazo zombini iziphelo zombhobho wentsimbi osongelweyo ugqunywe ngamabhodi amancinci omthi, kwaye umphezulu wangaphandle ubotshelelwe ngamabhanti entsimbi engatyiwayo ukuthintela ukudibana phakathi kweepayipi zentsimbi ngexesha lokuthuthwa kwaye kubangele ukungqubana. Iipayipi zentsimbi ezipakishiweyo zingena kwindawo yokubeka imveliso egqityiweyo.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Umthengi wethu

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.