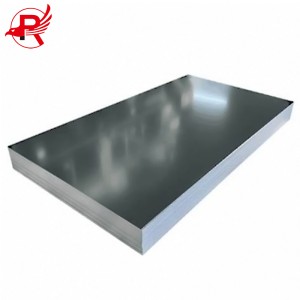

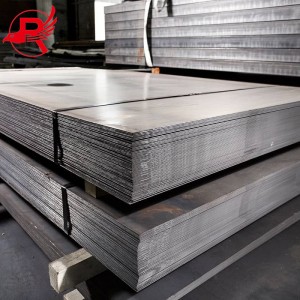

Ixabiso Eliphezulu Eliphezulu Eliyi-0.27mm Elishushu Elidityiweyo le-ASTM A653M-06a Iphepha Lentsimbi Eligayiweyo

Kukho iingenelo ezininzi zokusebenzisa ishiti yentsimbi egalelwe nge-galvanized:

1. Ukumelana nokugqwala: Ishidi lentsimbi eligayiweyo ligqunywe ngomaleko we-zinc, nto leyo eyenza ukuba likwazi ukumelana nokugqwala kakhulu.

2. Ukuqina:Ipleyiti yentsimbi egalelweyoihlala ixesha elide kwaye inokumelana neemeko zemozulu ezigqithisileyo, nto leyo eyenza ukuba ibe lukhetho oluhle kakhulu kwiindlela zangaphandle.

3. Ukusebenza kakuhle kweendleko: Ishidi lesinyithi eligayiweyo lingabizi kakhulu xa lithelekiswa nezinye iintsimbi, nto leyo eyenza ukuba libe lukhetho oluthandwayo kwiindlela ezahlukeneyo zokusetyenziswa.

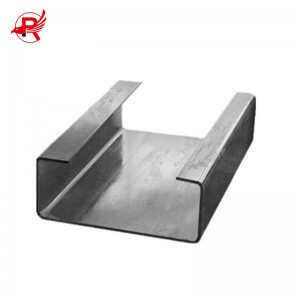

4. Kulula ukusebenza ngayo: Ishiti yentsimbi egayiweyo kulula ukuyisebenzisa kwaye inokwakheka ngokulula ibe ziimo ezahlukeneyo kunye nobukhulu obahlukeneyo.

5. Ulondolozo oluphantsi: Ishidi lentsimbi eligayiweyo alifuni ulondolozo oluncinci, nto leyo eyenza ukuba libe yinto engenangxaki kwiintlobo ngeentlobo zezicelo.

6. Ukumelana nomlilo: Ishidi lentsimbi eligayiweyo alitshi, nto leyo eyenza ukuba lilungele ukusetyenziswa kulwakhiwo nakwimisebenzi yemizi-mveliso.

1. Ukumelana nokugqwala, ukupeyinta, ukwakheka kakuhle kunye nokudityaniswa kwamabala.

2. Inoluhlu olubanzi lokusetyenziswa, ikakhulu isetyenziselwa izixhobo zasekhaya ezincinci ezifuna inkangeleko entle, kodwa ibiza kakhulu kune-SECC, ngoko ke abavelisi abaninzi batshintshela kwi-SECC ukuze bonge iindleko.

3. Yahlulwe yizinc: ubungakanani be-span kunye nobukhulu bomaleko wezinc bunokubonisa umgangatho we-galvanizing, okukhona incinci kwaye ityebile kokukhona ingcono. Abavelisi banokongeza unyango oluchasene nokuprintwa kweminwe. Ukongeza, inokwahlulwa ngokugqunywa kwayo, njenge-Z12, oko kuthetha ukuba isixa sisonke sokugqunywa kumacala omabini yi-120g/mm.

Iphepha leNtsimbi elisegadini, ekwaziwa ngokuba yi-galvanized steel sheet okanye i-zinc-coated sheet, luhlobo lwe-steel sheet egqunywe ngomaleko we-zinc ukuthintela ukuba ingagqwali. Ukusetyenziswa kwe-galvanized sheet kuxhaphake kakhulu ngenxa yokuqina kwayo okuhle kunye nokumelana nokugqwala. Eli nqaku liphonononga ukusetyenziswa kwayo kwiindlela ezahlukeneyo zokusebenza kumashishini ahlukeneyo.

Ishishini Lokwakha: Kwishishini lokwakha, amashiti e-galvanized adla ngokusetyenziswa ekufakeni uphahla kunye nokufakwa kwe-cladding. Ngenxa yokuqina kwawo kunye nokukwazi kwawo ukumelana neemeko zemozulu ezinzima, aye aba lukhetho oludumileyo lophahla lwezindlu, lwezorhwebo, nolwemizi-mveliso. Amashiti e-galvanized asetyenziswa kakhulu ekwakhiweni kwezakhiwo ezenziwe ngesakhelo sentsimbi, iibhulorho, kunye neendlela ezinkulu ngenxa yokuqina nokuthembeka kwawo.

Ishishini leeMoto:Ipleyiti yentsimbi eshushu egalelweyozisetyenziswa kakhulu kwishishini leemoto. Zisetyenziswa ekuveliseni imizimba yeemoto, itshasi, kunye nezinye iindawo ngenxa yokuxhathisa kwazo ukugqwala kunye nokukwazi ukumelana namaqondo obushushu aphezulu kunye nokufuma okuphezulu. Amaphepha e-galvanized akwasetyenziswa njengesithinteli sokugqwala ukwandisa ubomi beendawo zeemoto.

Ishishini lezoLimo: Ishishini lezolimo lisebenzisa amashiti e-galvanized kwiintlobo ngeentlobo zezinto ezifana nokwenza iishedi, ii-silos, izindlu zezilwanyana, kunye nocingo. Oku kungenxa yokukwazi kwawo ukumelana neemeko zemozulu ezahlukeneyo kunye nokumelana nokugqwala, okuqinisekisa ukuqina okuhlala ixesha elide kwezi zakhiwo.

Ishishini Lombane: Amaphepha e-galvanized asetyenziswa kakhulu kwishishini lombane ukwenza izakhiwo kunye nezinto ezihlala ixesha elide nezihlala ixesha elide ezifana neekheyiji zezixhobo zombane, ii-conduit zesinyithi, izixhobo zokukhanyisa, kunye nezixhobo zocingo.

Ishishini lezixhobo: Amashiti e-galvanized asetyenziswa kakhulu ekuveliseni izixhobo ezahlukeneyo zasekhaya ezifana neeyunithi zomoya opholileyo, iifriji, kunye noomatshini bokuhlamba. Ezi zixhobo zifuna izinto eziqinileyo nezihlala ixesha elide ezinokumelana neempembelelo zeekhemikhali ezibangelwa kukuvezwa kwizinto ezahlukeneyo, okwenza amashiti e-galvanized abe lukhetho olufanelekileyo.

Izicelo Zemizi-mveliso: Amaphepha e-galvanized asetyenziswa kwizicelo ezahlukeneyo zemizi-mveliso ezifana neetanki zokugcina, iipayipi, kunye nezixhobo zokucubungula. Asetyenziswa kwezi zicelo kuba anokumelana neemeko ezinzima zendalo kunye neekhemikhali ezirhabaxa ezinokubandakanyeka kwiinkqubo zoshishino.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.