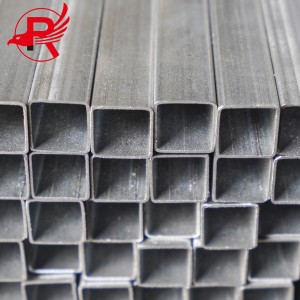

Umthengisi waseTshayina i-ASTM Ityhubhu yentsimbi engagqwaliyo engama-309 310 310S engangeni bushushu

| i-tem | Umbhobho wentsimbi engagqwaliyo we-309 310 310S |

| Umgangatho | I-JIS, i-AiSi, i-ASTM, i-GB, i-DIN, i-EN |

| Indawo yemvelaphi | iTshayina |

| Igama lebrand | UBUKHOSI |

| Uhlobo | Ayinamthungo / idityanisiwe |

| Isicelo | Ishishini leekhemikhali, izixhobo zoomatshini |

| Inkonzo Yokucubungula | Ukugoba, Ukuwelda, Ukuhombisa, Ukubethela, Ukusika, Ukubumba |

| Ubuchule | Iqengqiwe ngobushushu/iqengqiwe ngokubandayo |

| Immimiselo yokuhlawula | I-L/CT/T (30%IDEPOSIT) |

| Ixesha lexabiso | I-CIF CFR FOB EX-WORK |

Iimbonakalo

Ukumelana nobushushu obuphezulu: Inokuhlala izinzile kumaqondo obushushu aphezulu kakhulu kwaye ifanelekile kwiindawo ezinobushushu obuphezulu. Umzekelo, ezinye iipleyiti zentsimbi engagqwaliyo ezimelana nobushushu zinokumelana namaqondo obushushu angama-1035℃ nangaphezulu.

Ukumelana nokugqwala: Inokumelana nokugqwala okugqwesileyo kwaye ayiboli okanye yonakale lula kwii-asidi ezahlukeneyo ezinamandla, ii-alkalis ezinamandla kunye neendawo zokugqwala ezinobushushu obuphezulu. Ingasebenza ngokuzinzileyo kwiindawo zokugqwala ezifana neshishini leekhemikhali kunye namandla.

Amandla aphezulu oomatshini: Isenokugcina iipropati ezilungileyo zoomatshini kwiindawo ezinobushushu obuphezulu, ezinje ngamandla aphezulu, ubulukhuni obuphezulu, ukumelana nokuguguleka okuphezulu, njl.njl., kwaye inokumelana noxinzelelo kunye noxinzelelo phantsi kobushushu obuphezulu.

I-coefficient yokwandisa ubushushu obuphantsi: Ukuguquguquka okuncinci kwiindawo ezinobushushu obuphezulu, okuqinisekisa uzinzo lwesakhiwo kunye nokunciphisa ukuguquguquka kunye noxinzelelo olubangelwa kukutshintsha kobushushu.

Ukumelana kakuhle ne-oxidation: Akulula ukuyicola nokuyisusa xa kushushu kakhulu, kwaye ingasetyenziswa kwiindawo ezishushu kakhulu ixesha elide, nto leyo eyandisa ubomi benkonzo yesixhobo.

Ukusebenza kakuhle kokucubungula: Ingacutshungulwa ngeendlela ezahlukeneyo zokucubungula ezifana nokuwelda, ukusika, ukunyathela, ukwenza i-cold form kunye nokukhupha i-hot extrusion, kwaye kulula ukuyicubungula ibe ziimo ezahlukeneyo kunye nobukhulu ukuze kuhlangatyezwane neemfuno zokuvelisa kwiinkalo ezahlukeneyo.

Iimodeli eziqhelekileyo kunye nokusebenza

0Cr25Ni20 (310S): ekwaziwa ngokuba yi-2520, umxholo we-nickel uphakathi kwe-19%-22%, unokumelana nokufudumeza kwi-1035℃, sisixhobo se-SUS316 esiqinileyo se-liner yentsimbi engagqwaliyo, esisetyenziswa kakhulu kwizixhobo ze-oven, izixhobo zokucoca iimoto, njl.njl.

2Cr25Ni20: inokumelana nokufudumeza okuphindaphindiweyo ngaphantsi kwe-1035℃, yeyentsimbi engamelaniyo ne-oxidation, esetyenziselwa iindawo zesithando somlilo, imilomo, amagumbi okutsha, njl.njl.

1Cr16Ni35: ukumelana kakuhle ne-carburization kunye ne-nitriding, inokufudunyezwa ngokuphindaphindiweyo ngaphantsi kwe-1035℃, isetyenziselwa ikakhulu intsimbi yesithando somlilo.

2Cr25N: ukumelana okunamandla nokugqwala kobushushu obuphezulu, akukho sikali se-oxide esilula ukusixobula ngaphantsi kwe-1082℃, esisetyenziswa rhoqo kumagumbi okutsha

Intsimbi engagqwaliyo yeFerritic. Iqulethe i-12% ukuya kwi-30% ye-chromium. Ukumelana kwayo nokugqwala, ukuqina kwayo kunye nokudityaniswa kwayo kuyanda ngokwanda komxholo we-chromium, kwaye ukumelana kwayo nokugqwala kungaphezulu kunezinye iintlobo zentsimbi engagqwaliyo.

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Umbhobho weNtsimbi engagqwaliyo waseTshayinaIzinto ezidityanisiweyo zeekhemikhali

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Uphuhliso lwemizi-mveliso lutshintsha ngokukhawuleza, kwaye imibhobho yentsimbi engagqwaliyo ilandela uphuhliso lwemizi-mveliso ukuhlangabezana neemfuno zophuhliso lwemizi-mveliso eyahlukeneyo. Nazi iindlela ezibanzi zokusetyenziswaimibhobho engqukuva yentsimbi engagqwaliyokumashishini ahlukeneyo:

Ukunikezelwa kwamanzi kunye nemibhobho yokukhupha amanzi, iinkqubo zokunkcenkceshela

Ubunjineli bokuhambisa amanzi kunye nemibhobho yokuhambisa amanzi bujoliswe kushishino lothutho kunye nokusasazwa kwamanzi. Ukusela kunye nokuqokelelwa kwamanzi. Ukuthuthwa kunye nokukhutshwa kwamanzi amdaka kwimizi-mveliso. Ubunjineli benkqubo yelindle yasekhaya kunye nemibhobho yamanzi emvula (itshaneli).

Utyalo-mali lobunjineli lubangela uninzi lotyalo-mali olupheleleyo lobunjineli. Iinkqubo zokunkcenkceshela ezifafazwayo ziyinxalenye ebalulekileyo yokusetyenziswa kwamanzi kwezolimo. Iimpawu zomzimba nezekhemikhali zemibhobho yamanzi yentsimbi engagqwaliyo ziyahlangabezana neemfuno zokucoca amanzi kwezolimo kwanamhlanje.

Ezi ndlela zoqhagamshelo zineendawo ezahlukeneyo zokusetyenziswa ngokwemigaqo yazo eyahlukeneyo, kodwa uninzi lwazo kulula ukuzifaka, zomelele kwaye zithembekile. Indandatho yokutywina okanye izinto zegasket ezisetyenziselwa uqhagamshelo zenziwe kakhulu ngerabha ye-silicone, irabha ye-nitrile kunye nerabha ye-EPDM ezihlangabezana nemigangatho yesizwe, nto leyo ekhulula abasebenzisi kwiingxaki.

1. Ukupakishwa kwephepha leplastiki

Ngexesha lokuthuthwa kwemibhobho yentsimbi engagqwaliyo, amaphepha eplastiki adla ngokusetyenziswa ukupakisha imibhobho. Le ndlela yokupakisha iluncedo ekukhuseleni umphezulu wombhobho wentsimbi engagqwaliyo ekugugeni, ekukrweleni nasekungcoleni, kwaye ikwadlala indima ekukhuseleni ukufuma, uthuli kunye nokungagqwali.

2. Ukupakisha iteyiphu

Ukupakishwa kwetheyiphu yindlela efikelelekayo, elula nelula yokupakisha imibhobho yentsimbi engagqwaliyo, ngokuqhelekileyo kusetyenziswa iteyiphu ecacileyo okanye emhlophe. Ukusetyenziswa kokupakishwa kwetheyiphu akunakukhusela kuphela umphezulu wombhobho, kodwa kukwaqinisa amandla ombhobho kwaye kunciphise amathuba okushenxa okanye ukujika kombhobho ngexesha lokuthuthwa.

3. Ukupakishwa kwepalethi yomthi

Ekuthuthweni nasekugcinweni kwemibhobho emikhulu yentsimbi engagqwaliyo, ukupakishwa kwepallet yomthi yindlela eluncedo kakhulu. Imibhobho yentsimbi engagqwaliyo inamathele kwipallet ngeemicu zentsimbi, ezinokubonelela ngokhuseleko oluhle kakhulu kwaye zithintele ukuba imibhobho ingangqubani, igobeke, ingasebenzi kakuhle, njl.njl. ngexesha lokuthuthwa.

4. Ukupakisha ibhokisi

Kwiipayipi ezincinci zentsimbi engagqwaliyo, ukupakisha iibhokisi yindlela eqhelekileyo. Inzuzo yokupakisha iibhokisi kukuba ilula kwaye kulula ukuyithutha. Ukongeza ekukhuseleni umphezulu wombhobho, inokuba lula ukuyigcina nokulawula.

5. Ukupakisha izikhongozeli

Kwimibhobho emikhulu yentsimbi engagqwaliyo ethunyelwa kwamanye amazwe, ukupakisha izikhongozeli yindlela eqhelekileyo. Ukupakisha izikhongozeli kunokuqinisekisa ukuba imibhobho ithuthwa ngokukhuselekileyo kwaye ngaphandle kweengozi elwandle, kwaye kuthintelwe ukuphambuka, ukungqubana, njl.njl. ngexesha lokuthuthwa.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Umthengi wethu

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi beetyhubhu zentsimbi ezijikelezayo ezikwilali yaseDaqiuzhuang, kwisixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ngaba unexabiso eliphezulu lokuhlawula?

A: I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka eli-13 kwaye samkela isiqinisekiso sorhwebo.