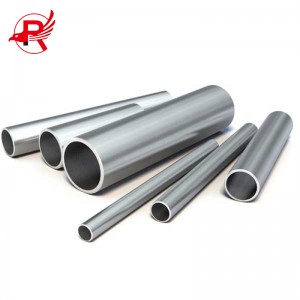

Ityhubhu ye-SS ejikelezileyo ehonjisiweyo e-SUS 304L 316 316L 304 Umbhobho/ityhubhu yentsimbi engagqwaliyo

| Igama lemveliso | Ipayipi engqukuva yentsimbi engenasici |

| Umgangatho | I-ASTM AISI DIN, EN, GB, JIS |

| Ibanga lentsimbi

| Uthotho lwama-200: 201,202 |

| Uthotho lwe-300: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| Uthotho lwe-400: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Intsimbi yeDuplex: 904L, 2205, 2507, 2101, 2520, 2304 | |

| Ububanzi obungaphandle | 6-2500mm (njengoko kufuneka) |

| Ubukhulu | 0.3mm-150mm (njengoko kufuneka) |

| Ubude | 2000mm/2500mm/3000mm/6000mm/12000mm (njengoko kufuneka) |

| Ubuchule | Akukho mthungo |

| Umphezulu | Inombolo 1 2B BA 6K 8K Isipili Inombolo 4 HL |

| Ukunyamezelana | ±1% |

| Imigaqo yeXabiso | I-FOB, i-CFR, i-CIF |

Umbhobho wentsimbi engagqwaliyo luhlobo lwentsimbi ende engqukuva engenanto, esetyenziswa kakhulu kwiipayipi zothutho lwemizi-mveliso ezifana nepetroleum, imboni yeekhemikhali, unyango lwezonyango, ukutya, imboni yokukhanya, izixhobo zoomatshini, njl.njl., kunye nezixhobo zesakhiwo soomatshini. Ukongeza, xa amandla okugoba kunye nokujika kwemithambo efana, ubunzima bulula, ngoko ke ikwasetyenziswa kakhulu ekwenziweni kweendawo zoomatshini kunye nezakhiwo zobunjineli. Ikwasetyenziswa njengefenitshala kunye nezixhobo zasekhitshini, njl.njl.

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Iinxalenye zeekhemikhali zePipe yentsimbi engagqwaliyo

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa iindlela ezahlukeneyo zokucubungula ukuqengqeleka okubandayo kunye nokuphinda kusetyenzwe umphezulu emva kokuqengqeleka, ukugqitywa komphezulu wentsimbi engagqwaliyoibhaii-s zinokuba neentlobo ezahlukeneyo.

Umgangatho womphezulu wentsimbi engagqwaliyo ubaluleke kakhulu kuba uchaphazela ngokuthe ngqo ukumelana nokugqwala kwawo. Ukugqwala yinto yendalo eyenzeka xa iintsimbi zisabela kwimeko-bume yeekhemikhali ezizingqongileyo, njengomoya okanye ukufuma.

Ngentsimbi engagqwaliyo, i-chromium ekwi-alloy yenza umaleko okhuselayo kumphezulu othintela isinyithi ukuba singasabelani nendawo esingqongileyo. Olu maleko lubizwa ngokuba yi-passivation film. Nangona kunjalo, ifilimu engagqwaliyo kwintsimbi engagqwaliyo ayinakutshatyalaliswa. Ukuba umphezulu wonakele okanye ungcolisiwe, ifilimu inokuqhekeka, ishiye isinyithi sisengozini yokugqwala. Yiyo loo nto ukugcina ucoceko kunye nokuthembeka kwemiphezulu yentsimbi engagqwaliyo kubalulekile.

Kukho iindlela ezahlukeneyo zokuphucula umgangatho wemiphezulu yentsimbi engagqwaliyo. Enye indlela kukusebenzisa inkqubo ebizwa ngokuba yi-passivation. Oku kubandakanya ukunyanga umphezulu ngesisombululo esikhethekileyo esisusa naluphi na ukungcola kwaye siphucule iipropati zokukhusela zefilimu engagqwaliyo. I-passivation inokufezwa ngeendlela ezahlukeneyo ezifana neebhafu zamakhemikhali okanye i-electropolishing.

Enye indlela yokugcina umgangatho weendawo zentsimbi engagqwaliyo kukucoca nokulungisa rhoqo. Iindawo zentsimbi engagqwaliyo mazicocwe ngesepha ethambileyo kunye nelaphu elithambileyo, kwaye naziphi na iziphene eziqinileyo okanye ukujika kombala kunokususwa ngeemveliso zokucoca ezikhethekileyo.

Lilonke, ukubaluleka kokugqitywa kwentsimbi engagqwaliyo akunakugxininiswa kakhulu. Umgangatho womphezulu ubalulekile ukuqinisekisa ukuqina kunye nobude bexesha lezinto. Ngokulandela iinkqubo ezifanelekileyo zokucoca kunye nokulungisa, intsimbi engagqwaliyo inokuqhubeka nokubonelela ngokusebenza okuphezulu kunye nokuhombisa ubuhle iminyaka emininzi ezayo.

Intsimbi engagqwaliyo yaziwa ngokuqina kwayo, ukumelana nokugqwala kunye nokuguquguquka kwayo. Isetyenziswa kakhulu kwizicelo ezahlukeneyo kuquka ukuveliswa kwemibhobho.

Umbhobho wentsimbi engagqwaliyo usetyenziswa kakhulu kwiindawo zoshishino nasekwakheni izakhiwo nezakhiwo. Inkqubo yokuvelisa umbhobho wentsimbi engagqwaliyo yinkqubo enzima equka amanyathelo amaninzi.

Impahla engekasilwa

Inyathelo lokuqala ekwenzeni umbhobho wentsimbi engagqwaliyo kukufumana izinto ezikrwada. Eyona nto iphambili kwintsimbi engagqwaliyo yintsimbi, kodwa idityaniswe nezinye izinto ukuze inike iimpawu zayo ezikhethekileyo. Ezi zinto ziquka i-nickel, i-chromium kunye ne-molybdenum. Izinto ezikrwada zikhethwa ngononophelo kwaye zidityaniswe ngokulinganayo ukuvelisa umgangatho ofunekayo wentsimbi engagqwaliyo. Ezi zinto emva koko zinyibilikiswa kunye kwisithando sobushushu obuphezulu, apho zidityaniswe khona ukuze zenze i-alloy. Xa i-alloy yenziwe, igalelwa kwi-mold ukuqala inkqubo yokubumba izinto. Ii-mold, ezihlala zenziwe ngesanti okanye nge-ceramic, zenzelwe ukwenza iityhubhu ezingenanto ekupheleni kwenkqubo. Emva kokuba i-alloy igalelwe kwi-mold, ivunyelwe ukuba iphole kwaye iqine. Imo yokugqibela yityhubhu enemiphetho erhabaxa kunye nomphezulu ongalinganiyo.

skrola

Inyathelo elilandelayo kule nkqubo kukuqengqeleka. Ityhubhu inikwa uthotho lweerola ezicinezela kwaye zibumbe izinto, nto leyo ephumela kumphezulu olinganayo nobubanzi obuhambelanayo. Emva koko ityhubhu idlula kwi-mandrel ukuqinisekisa ukuba ijikelezile ngokugqibeleleyo kwaye ubukhulu bodonga buyafana. Le nkqubo, eyaziwa ngokuba yi-sizeing, ibalulekile ekuqinisekiseni ukuba imveliso egqityiweyo iyahlangabezana neemfuno ezifunekayo.

Ukusika kunye nokugqiba

Nje ukuba ityhubhu ilinganiswe ngobukhulu, lixesha lokuyisika nokugqiba. Oku kuquka ukuyisika ityhubhu ibe nobude obufunekayo kunye nokugudisa imiphetho okanye iibherrs ezirhabaxa. Emva koko ityhubhu iyapholishwa ukuze igqibele kakuhle, ikhazimle. Le nkqubo inceda ekwandiseni ukumelana nokugqwala kombhobho kwaye iwenze ube nenkangeleko entle.

Uvavanyo kunye nokuhlolwa

Iimveliso ezigqityiweyo kufuneka zivavanye kwaye zihlolwe ngokucokisekileyo ngaphambi kokuba zithengiswe. Jonga ityhubhu ukuba ayinazo naziphi na iziphene ezifana nokuqhekeka okanye amabala okugqwala. Ikwaphumelele uvavanyo lokuqina, ukuqina kunye nokumelana nokugqwala. Nje ukuba ityhubhu iphumelele zonke iimvavanyo kunye nokuhlolwa okufunekayo, ilungele ukusetyenziswa. Ityhubhu yentsimbi engatyiwayo eyenziwa kusetyenziswa le nkqubo isetyenziswa kumashishini ahlukeneyo, kubandakanya ulwakhiwo, ioyile negesi, kunye nokuvelisa.

Ngamafutshane, ukuveliswa kwemibhobho yentsimbi engagqwaliyo yinkqubo enzima enamanyathelo amaninzi equka amanqanaba amaninzi ukusuka kwizinto eziluhlaza ukuya kwiimveliso ezigqityiweyo. Ifuna ingqalelo enzulu kwiinkcukacha, ukuchaneka kunye nolawulo lomgangatho ukuqinisekisa ukuba imveliso egqityiweyo iyahlangabezana neemfuno ezifunekayo kwaye ifanelekile kwiintlobo ngeentlobo zezicelo.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Umthengi wethu

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi beetyhubhu zentsimbi ezijikelezayo kwisixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.