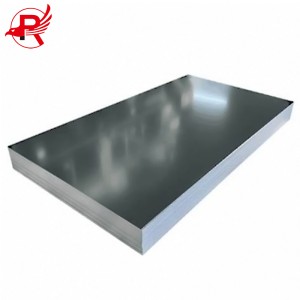

Ishidi lentsimbi eshushu edityiweyo ye-DX52D+AZ150

Ishidi lesinyithiIbhekisa kwishiti yentsimbi egqunywe ngomaleko we-zinc phezu komphezulu. I-Galvanizing yindlela yokuthintela umhlwa engabizi kakhulu nesebenzayo esetyenziswa rhoqo, kwaye malunga nesiqingatha semveliso ye-zinc ehlabathini isetyenziswa kule nkqubo.

Ngokweendlela zokuvelisa kunye nokucubungula, ingahlulwahlulwa ibe ziindidi ezilandelayo:

Ipleyiti yentsimbi eshushu egalelweyo. Nciphisa ipleyiti yesinyithi ebhityileyo kwi-zinc tank etyhidiweyo ukuze wenze ipleyiti yesinyithi ebhityileyo enomaleko we-zinc enamathele kumphezulu wayo. Okwangoku, inkqubo eqhubekayo yokwenza i-galvanizing isetyenziselwa kakhulu ukuvelisa, oko kukuthi, ipleyiti yesinyithi ebhityileyo iqhubeka intywiliselwa kwi-galvanizing tank ene-zinc etyhidiweyo ukwenza ipleyiti yesinyithi etyhidiweyo;

Ipleyiti yentsimbi egalelweyo exutyiweyo. Olu hlobo lwephaneli yentsimbi lwenziwa ngendlela yokuntywila eshushu, kodwa ifudunyezwa ifikelele kuma-500℃ emva nje kokuba iphumile etankini, ukuze yenze ifilimu ye-alloy ye-zinc kunye ne-iron. Le phepha le-galvanized linamathele kakuhle kwipeyinti kwaye liyakwazi ukuwelda;

Ipleyiti yentsimbi egalelwe nge-electro-galvanized. Iphaneli yentsimbi egalelwe nge-electroplating inokulungiswa kakuhle. Nangona kunjalo, ulusu luncinci kwaye ukumelana nokugqwala kwalo akulunganga njengolu lweshiti zegalvini ezishushu

1. Ukumelana nokugqwala, ukupeyinta, ukwakheka kakuhle kunye nokudityaniswa kwamabala.

2. Inoluhlu olubanzi lokusetyenziswa, ikakhulu isetyenziselwa izixhobo zasekhaya ezincinci ezifuna inkangeleko entle, kodwa ibiza kakhulu kune-SECC, ngoko ke abavelisi abaninzi batshintshela kwi-SECC ukuze bonge iindleko.

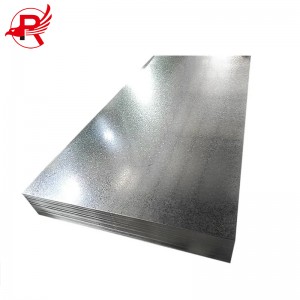

3. Yahlulwe yizinc: ubungakanani be-span kunye nobukhulu bomaleko wezinc bunokubonisa umgangatho we-galvanizing, okukhona incinci kwaye ityebile kokukhona ingcono. Abavelisi banokongeza unyango oluchasene nokuprintwa kweminwe. Ukongeza, inokwahlulwa ngokugqunywa kwayo, njenge-Z12, oko kuthetha ukuba isixa sisonke sokugqunywa kumacala omabini yi-120g/mm.

Iphepha leNtsimbi elisegadinikwaye iimveliso zentsimbi ezisikiweyo zisetyenziswa kakhulu kumashishini okwakha, amashishini alula, iimoto, ezolimo, ukufuya izilwanyana, ukuloba kunye namashishini orhwebo. Phakathi kwazo, ishishini lokwakha lisetyenziswa kakhulu ukuvelisa iiphaneli zophahla lwezakhiwo zoshishino kunye nezoluntu ezilwa nokugqwala, iigridi zophahla, njl.njl.; ishishini loshishino lokukhanya lisebenzisa lona ukuvelisa amagobolondo ezixhobo zasekhaya, iitshimini zombane, izixhobo zasekhitshini, njl.njl., kwaye ishishini leemoto lisetyenziswa kakhulu ukuvelisa iindawo zeemoto ezingamelani nokugqwala, njl.njl.; Ezolimo, ukufuya izilwanyana kunye nokuloba zisetyenziselwa kakhulu ukugcina nokuthuthwa kweenkozo, inyama ekhenkcezisiweyo kunye neemveliso zasemanzini, njl.njl.; ishishini lisetyenziselwa kakhulu ukugcina nokuthuthwa kwezinto, izixhobo zokupakisha, njl.njl.

| Inkcazo | ||||

| Imveliso | Ipleyiti yentsimbi egalelweyo | |||

| Izinto eziphathekayo | I-SGCC,SGCH,G350,G450,G550,DX51D,DX52D,DX53D | |||

| Ubukhulu | 0.12-6.0mm | |||

| Ububanzi | 20-1500mm | |||

| Ugqubuthelo lwezinki | I-Z40-600g/m2 | |||

| Ukuqina | Iqinile ethambileyo (60), eqinileyo ephakathi (HRB60-85), eqinileyo epheleleyo (HRB85-95) | |||

| Ulwakhiwo lomphezulu | I-spangle eqhelekileyo, Ubuncinci bespangle, i-Zero spangle, ispangle esikhulu | |||

| Unyango lomphezulu | I-Chromated/Ayinayo iChromated, Inamafutha/Ayinayo ioyile, Isikhumba sidlula | |||

| Iphakheji | Igqunywe ngomaleko weplastiki kunye nekhadibhodi, ipakishwe iipallets zomthi/ukupakisha intsimbi, ezibotshwe ngebhanti yentsimbi, ezifakwe kwizikhongozeli. | |||

| Imigaqo yeXabiso | I-FOB, i-EXW, i-CIF, i-CFR | |||

| Immimiselo yokuhlawula | I-30% TT yediphozithi, i-70% TT | |||

| Ixesha lokuthunyelwa | Iintsuku zokusebenza eziyi-7-15 emva kokufumana idiphozithi ye-30% | |||

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.