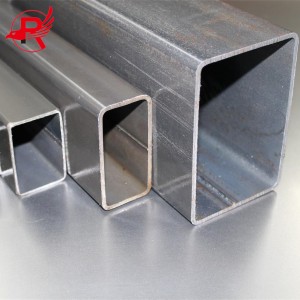

Ityhubhu yePipe yeCarbon eNzima eWelded & engenamthungo eshushu eqengqelekayo yeCarbon Steel Square Rectangular

Umbhobho weCarbon Steel Rectangularyintsimbi-khabhoni edibeneyo enomxholo wekhabhoni0.0218% ukuya kwi-2.11%. Ikwabizwa ngokuba yintsimbi yekhabhoni. Ngokuqhelekileyo ikwaqulathe inani elincinci le-silicon, i-manganese, i-sulfur, ne-phosphorus. Ngokubanzi, okukhona umxholo wekhabhoni uphezulu kwintsimbi yekhabhoni, kokukhona ubulukhuni bukhula kwaye amandla aphezulu, kodwa kokukhona i-plasticity iphantsi.

| Into | Inkcazo / Inkcazo |

| Imigangatho yezinto eziphathekayo | GB/T (eTshayina), EN 10210 / EN 10219 (eYurophu), ASTM A500 / ASTM A513 (e-USA) |

| Ubukhulu | Ubude: 6–12 m (inokulungiselelwa) |

| Ububanzi / Ubude: 20×20 mm – 500×500 mm | |

| Ubukhulu bodonga: 1.5–20 mm | |

| Indlela yoMveliso | Igoqwe ngobushushu, yenziwe ngobandayo, ayinamthungo, okanye idityanisiwe |

| Umphezulu wokugqiba | Mnyama, Igaleyivu, Ipeyintiwe, Ikhazimlisiwe |

| Iinkonzo zokucubungula | Ukusika, Ukubhola, Ukugoba, Ukuwelda, Ukuxovula, Ukwenza imisonto, Ukwenza ngokwezifiso |

| Uhlolo kunye noVavanyo | Uvavanyo lweMilinganiselo, Uvavanyo lwePropati yoMatshini, Uvavanyo loBume beeKhemikhali, Uvavanyo lweUltrasonic okanye lweHydrostatic |

| Ukupakisha | Zihlanganiswe ngemitya yentsimbi, iibhokisi zomthi, ukusonga ngeplastiki, okanye ukupakishwa ngokwezifiso ngokweemfuno zomthengi |

Iumbhobho ongxandeIsetyenziswa kakhulu kulwakhiwo, oomatshini, ukwakha iinqanawa, amandla ombane, ezolimo kunye nokufuya izilwanyana, ukugcina izinto, ukukhusela umlilo, izixhobo zasekhaya kunye neminye imboni, kwaye kunokuthiwa yintsimbi ebalulekileyo kuphuhliso lwanamhlanje lwemizi-mveliso.

Phawula:

1. Mahala iisampulu,100%uqinisekiso lomgangatho emva kokuthengisa, kunyeinkxaso yayo nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeimibhobho yentsimbi yekhabhoniingabonelelwa ngokweemfuno zakho (I-OEM kunye ne-ODM)! Uza kufumana ixabiso langaphambili lefektri kwiRoyal Group.

3. Ubuchwepheshalinkonzo yokuhlolwa kwemveliso,ulwaneliseko oluphezulu lwabathengi.

4. Umjikelo wemveliso umfutshane, kwaye80% ii-odolo ziya kuhanjiswa kwangaphambili.

5. Imizobo iyimfihlo kwaye yonke yenzelwe abathengi.

1. Iimfuno: amaxwebhu okanye imizobo

2. Ukuqinisekiswa komthengisi: ukuqinisekiswa kwesitayile semveliso

3. Qinisekisa ukwenziwa ngokwezifiso: qinisekisa ixesha lokuhlawula kunye nexesha lokuvelisa (idiphozithi yokuhlawula)

4. Imveliso xa ifunwa: ilinde ukuqinisekiswa kwerisithi

5. Qinisekisa ukuhanjiswa: hlawula ibhalansi uze uhambise

6. Qinisekisa irisithi

Inkqubo yokuvelisa imibhobho yentsimbi edibeneyo yesikwere idla ngokubandakanya la manyathelo aphambili alandelayo, kwaye inkqubo ethile inokulungiswa ngokuxhomekeke kwizixhobo zokuvelisa kunye neenkcukacha zemveliso:

1. Ukulungiswa kwezinto eziluhlaza

Ukukhetha imicu yentsimbi: Sebenzisa umcu wentsimbi oqengqelekayo oshushu okanye obandayo njengezinto eziluhlaza, kwaye ukhethe umcu wentsimbi ofanelekileyo (njengentsimbi yekhabhoni, intsimbi ye-alloy, njl.njl.) ngokweenkcazo zemveliso (ezifana nobukhulu bodonga, ubungakanani).

Ukuvula nokulinganisa: Vula umcu wentsimbi ojijekileyo ngomatshini ovulayo, kwaye usebenzise umatshini wokulinganisa ukuze ususe imo yamaza okanye ukugoba komcu wentsimbi ukuqinisekisa ukuba umphezulu uthambile.

2. Ukwenziwa

Ukugoba kwangaphambili kunye nokwakheka okurhabaxa: Umcu wentsimbi ugoba kancinci kancinci ngeeseti ezininzi zeerola ukuze zenze iprofayili yokuqala yoxande. Ngokwesiqhelo iteknoloji "yokwenza ukugoba okubandayo" isetyenziselwa ukuthintela ukuqina kwezinto.

Ukwakheka kakuhle: Sebenzisa iimolds ezichanekileyo ukuze ulungise ngakumbi imo ukuqinisekisa ukuchaneka kobukhulu bombhobho wentsimbi yesikwere (njengobude becala, ukuma nkqo).

3. Ukuwelda

Ukuwelda okuxhathisayo rhoqo (ERW):

Lungelelanisa imiphetho yomcu wentsimbi owenziweyo kwaye ufudumale imiphetho yomcu wentsimbi ibe kwimeko enyibilikisiweyo ngokusebenzisa umsinga ojikelezayo ophezulu.

Faka uxinzelelo ukuze udibanise imiphetho ukuze wenze i-weld eqhubekayo.

Ukuwelda kwe-Arc efakwe emanzini (i-SAW):

Isetyenziswa kwimibhobho yentsimbi enobubanzi obukhulu okanye enodonga oluqinileyo, i-flux igqunywe kwi-weld, kwaye ucingo lwe-welding kunye nezinto ezisisiseko ziyanyibilikiswa yi-arc ukuze zenze i-weld.

4. Ukucubungula iWeld

Ukususa iimbumbulu: Sebenzisa isixhobo sokusika okanye ivili lokugaya ukususa iimbumbulu kumphezulu wangaphakathi nowangaphandle we-weld ukuqinisekisa ukuba umphezulu uthambile.

Ukufunyanwa kweziphene zeWeld: Sebenzisa i-ultrasound okanye i-X-ray ukuze ufumane iziphene zangaphakathi kwiweld (ezifana neembobo kunye nokungabikho kwe-fusion).

5. Ubungakanani kunye nokuLungelelanisa

Umatshini wokulinganisa: Lungisa ukuchaneka kobukhulu bombhobho wentsimbi ngokuwuqengqa ukuqinisekisa ukuba ubude becala kunye nokujikeleza kuyahlangabezana nemigangatho.

Umatshini wokulungisa: Susa ukugoba kombhobho wentsimbi ngexesha lenkqubo yokwenza okanye yokuhlanganisa.

6. Ukuphola nokuSika

Ukupholisa: Sebenzisa ukupholisa ngamanzi okanye ukupholisa umoya ukunciphisa ubushushu bombhobho wentsimbi ukuze uphephe ukuguquka kobushushu.

Ukusika: Sebenzisa isarha ebhabhayo okanye isarha ejikelezayo ukusika umbhobho wentsimbi oqhubekayo ube nobude obufunekayo (njengeemitha ezi-6, iimitha ezili-12).

7. Unyango Lomphezulu

Ukucola/ukuphosphata: susa isikali se-oxide yomphezulu kunye nokungcola ukulungiselela unyango olulandelayo.

Ukupeyinta nge-galvanizing okanye ngopende: kuphucula ukumelana nokugqwala kwemibhobho yentsimbi ngokuyitshiza nge-hot-dip okanye ngokuyitshiza ngepeyinti yokulwa nokugqwala.

8. Uhlolo loMgangatho

Ukulinganiswa kobukhulu: jonga iiparameter ezifana nobude becala, ubukhulu bodonga, ubude, njl.

Uvavanyo lweempawu zoomatshini: uvavanyo lokuxinana, uvavanyo lokuchaphazeleka, njl.njl. ukuqinisekisa amandla kunye nokuqina kwezinto.

Ukuhlolwa kwenkangeleko: ngokubona okanye ngezixhobo ezizenzekelayo ukuze kufunyanwe iziphene zomphezulu (ezifana nemikrwelo, ukuqhekeka).

9. Ukupakishwa kunye nokugcinwa

Ukupakisha: iphakheji, ilebheli, okanye sebenzisa izinto ezingangenisi manzi xa upakisha ngokweemfuno zabathengi.

Indawo yokugcina: gcina ngokweendidi ukuze uphephe ukuguguleka okanye ukugqwala okubangelwa luxinzelelo olukhulu okanye indawo enomswakama.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Amanyathelo okhuseleko xa kupakishwa kwaye kuthuthwa imibhobho yentsimbi yekhabhoni

1. Imibhobho yentsimbi yekhabhoni mayikhuselwe kumonakalo obangelwa kukungqubana, ukukhupha kunye nokusikeka ngexesha lokuthuthwa, ukugcinwa kunye nokusetyenziswa.

2. Xa usebenzisaUmbhobho wentsimbi we-A36, kufuneka ulandele iinkqubo zokusebenza zokhuseleko ezifanelekileyo kwaye uqaphele ukuthintela ukuqhuma, imililo, ityhefu kunye nezinye iingozi.

3. Ngexesha lokusetyenziswa, imibhobho yentsimbi yekhabhoni mayiphephe ukudibana namaqondo obushushu aphezulu, izinto ezibangela ukubola, njl. Ukuba isetyenziswa kwezi ndawo, imibhobho yentsimbi yekhabhoni eyenziwe ngezinto ezikhethekileyo ezifana nokuxhathisa amaqondo obushushu aphezulu kunye nokuxhathisa ukubola kufuneka ikhethwe.

4. Xa ukhethaUmbhobho wentsimbi i-A53, imibhobho yentsimbi yekhabhoni enezinto ezifanelekileyo kunye neenkcukacha kufuneka ikhethwe ngokusekelwe kwizinto ezibanzi ezifana nendawo yokusetyenziswa, iipropati eziphakathi, uxinzelelo, ubushushu kunye nezinye izinto.

5. Ngaphambi kokuba kusetyenziswe imibhobho yentsimbi yekhabhoni, kufuneka kwenziwe uhlolo novavanyo olufunekayo ukuqinisekisa ukuba umgangatho wayo uyahlangabezana neemfuno.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Iinkonzo

Siziingcali kwiNkqubo yokuCwangcisa izinto ngokwezifiso.

Iqela lethu elinamava liza kusika, libumbe kwaye lidibanise izinto ngokweemfuno zakho. Siyindawo enye ethengisa izinto: Oda iimveliso ozifunayo, uzilungiselele ngokweemfuno zakho, kwaye ufumane ukuhanjiswa ngokukhawuleza nasimahla. Injongo yethu kukunciphisa umsebenzi kuwe—ukonga ixesha nemali.

Ukusarha, Ukucheba kunye nokusika ilangatye

Sinee-bandsaws ezintathu kwindawo leyo ezikwaziyo ukusika ii-miter. Sisika ipleyiti enobukhulu obuyi-⅜" ukuya kwi-4½", kwaye i-Cincinnati Shear yethu iyakwazi ukusika iphepha elincinci njenge-22 gauge kwaye linzima njenge-¼” square kwaye lichanekile. Ukuba ufuna izixhobo ezisikiweyo ngokukhawuleza nangokuchanekileyo, sinikezela ngenkonzo yosuku olufanayo.

Ukuwelda

Umatshini wethu wokuwelda weLincoln 255 MIG uvumela abawelda bethu abanamava ukuba bawelda naluphi na uhlobo lweekholamu zendlu okanye iintlobo ngeentlobo zeentsimbi ozifunayo.

Ukubhoboza Imingxunya

Siziingcali kwiipleyiti zentsimbi ezitshintshayo. Iqela lethu lingenza imingxunya emincinci njenge ⅛" ububanzi kunye ne 4¼" ububanzi. SineeHougen kunye neMilwaukee magnetic drill presses, ii-manual punches kunye nee-ironworkers, kunye nee-automatic CNC punches kunye nee-drill presses.

Ukunika iikontraka ezingaphantsi

Ukuba kuyimfuneko, siza kusebenzisana nomnye wamaqabane ethu amaninzi avela kulo lonke ilizwe ukukunika imveliso ekumgangatho ophezulu nengabizi kakhulu. Ubudlelwane bethu buqinisekisa ukuba iodolo yakho iphathwa ngokufanelekileyo ziingcali ezinamava kakhulu kushishino.

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi. Sinefektri yethu ekwiDaqiuzhuang Village, eTianjin City, eTshayina. Ngaphandle koko, sisebenzisana namashishini amaninzi karhulumente, afana neBAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, njl.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ngaba unexabiso eliphezulu lokuhlawula?

A: Kwi-odolo enkulu, i-L/C yeentsuku ezingama-30-90 ingamkeleka.

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wembasa yegolide iminyaka eli-13 kwaye sinikezela ngesiqinisekiso sorhwebo.