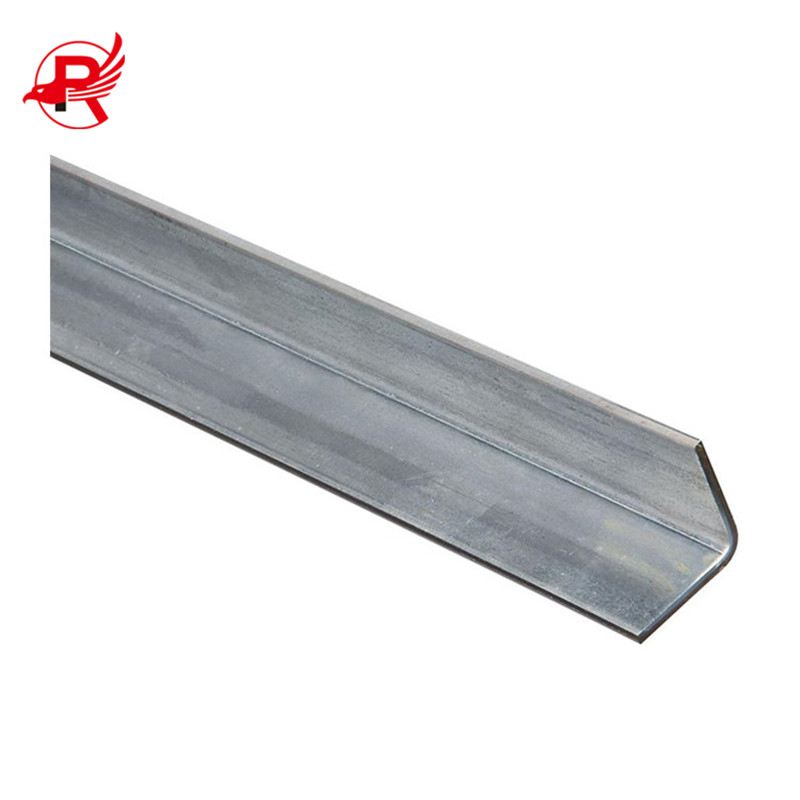

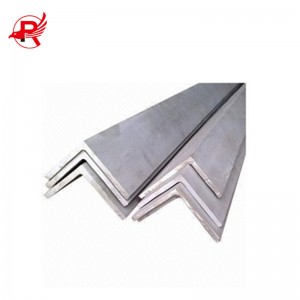

Ubungakanani obuqhelekileyo be-Hot Dip A36-300W Galvanized Steel Angle Bar

I-GalvanisedIbha yentsimbi ye-AngleYahlulwe yaba yintsimbi ye-angle ekhanyisiweyo eshushu kunye nentsimbi ye-angle ekhanyisiweyo ebandayo. Intsimbi ye-angle ekhanyisiweyo eshushu ikwabizwa ngokuba yintsimbi ye-angle ekhanyisiweyo eshushu okanye intsimbi ye-angle ekhanyisiweyo eshushu. I-cold-dip galvanized coating ikakhulu iqinisekisa unxibelelwano olupheleleyo phakathi komgubo we-zinc kunye nentsimbi ngomgaqo we-electrochemical, kwaye ivelisa umahluko onokubakho we-electrode wokulwa nokugqwala.

Intsimbi ye-angle egqunyiweyo eshushu ikwabizwa ngokuba yi-hot-dip galvanized angle steel okanye i-hot-dip galvanized angle steel. Yenzelwe ukuntywilisela intsimbi ye-angle emva kokunyibilikisa i-zinc enyibilikisiweyo malunga nama-500 ℃, ukuze umphezulu wentsimbi ye-angle unamathele ngomaleko we-zinc, ukuze kufezekiswe injongo yokulwa nokugqwala, kwaye ifanelekile kwiindawo ezahlukeneyo ezinamandla okugqwala ezifana ne-acid enamandla kunye ne-alkali mist.

Inkqubo: intsimbi ye-angle edityiweyo eshushu Inkqubo: ukugalela intsimbi ye-angle → ukuhlamba ngamanzi → ukuntywiliselwa kwi-plating solvent → ukomisa kunye nokufudumeza kwangaphambili → ukuplata i-rack → ukupholisa → ukucoca → ukugaya → ukugawula i-hot-dip kugqityiwe.

Inkqubo yokugaya isinyithi ebandayo isetyenziselwa ukukhusela iintsimbi ekuboleni. Ngenxa yesi sizathu, kusetyenziswa ugqubuthelo lwe-zinc filler. Lusetyenziswa kumphezulu ukuze lukhuselwe nangayiphi na indlela yokugaya. Emva kokomiswa, kwenziwa ugqubuthelo lwe-zinc filler. Kwigqubuthelo elomileyo. Inomxholo ophezulu we-zinc (ukuya kuthi ga kwi-95%). Ifanelekile kumsebenzi wokulungisa (oko kukuthi, ngexesha lomsebenzi wokulungisa, kuphela apho umphezulu wentsimbi okhuselweyo wonakele, unokuphinda usetyenziswe kwangoko emva kokuba umphezulu ulungisiwe). Inkqubo yokugaya isinyithi ebandayo isetyenziselwa ukuthintela ukubola kweemveliso ezahlukeneyo zentsimbi kunye nezakhiwo.

1. Iindleko zokucubungula eziphantsi: iindleko zokufaka i-hot-dip galvanizing kunye ne-anti-rust ziphantsi kunezo zezinye iingubo zokupenda;

2. Ihlala ixesha elide kwaye ihlala ixesha elide: ishushu-idiphu cIbha ye-Angle yentsimbi ye-arbonineempawu zokukhazimla komphezulu, umaleko we-zinc ofanayo, akukho plating ilahlekileyo, akukho manzi avuzayo, ukunamathela okuqinileyo kunye nokumelana okunamandla kokugqwala. Kwimeko-bume yasezidolophini, ubukhulu obuqhelekileyo be-hot-dip galvanized anti-rust bunokugcinwa Ngaphezulu kweminyaka engama-50 ngaphandle kokulungiswa; kwiindawo zasezidolophini okanye kwiindawo ezikude nolwandle, umaleko oqhelekileyo we-hot-dip galvanized anti-rust unokugcinwa iminyaka engama-20 ngaphandle kokulungiswa;

3. Ukuthembeka okulungileyo: ikhonkco lesinyithi phakathi komaleko we-galvanized kunye nezinto zentsimbi liba yinxalenye yomphezulu wentsimbi, ngoko ke ukuqina kwengubo kuthembeke ngakumbi;

4. Ukuqina kwengubo kuqinile: umaleko we-galvanized wenza isakhiwo esikhethekileyo se-metallurgical, esinokumelana nomonakalo woomatshini ngexesha lokuthuthwa nokusetyenziswa;

5. Ukhuseleko olupheleleyo: yonke indawo yeendawo ezifakwe iplastiki inokugqunywa nge-zinc, nokuba kusezingxondorheni, iikona ezibukhali kunye neendawo ezifihlakeleyo zinokukhuseleka ngokupheleleyo;

6. Gcina ixesha kunye nomgudu: inkqubo yokufaka i-galvanizing ikhawuleza kunezinye iindlela zokwakha i-coating, kwaye ingathintela ixesha elifunekayo lokupeyinta kwindawo yokwakha emva kokufakwa.

ibha ye-engile yentsimbi egalelweyoIsetyenziswa kakhulu kwiinqaba zamandla, iinqaba zonxibelelwano, izixhobo zodonga lwekhethini, ukwakhiwa kweeshelufu, oololiwe, ukhuseleko lwendlela, iipali zezibane zesitalato, izinto zaselwandle, izinto zesakhiwo sentsimbi, izibonelelo ezincedisayo zesitishi esingaphantsi, ishishini lokukhanya, njl.

| Igama lemveliso | AiBhari ye-ngle |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njl. |

| Uhlobo | Umgangatho we-GB, Umgangatho waseYurophu |

| Ubude | I-Standard 6m kunye ne-12m okanye ngokweemfuno zomthengi |

| Ubuchule | Ishushu Eqengqelekayo |

| Isicelo | Isetyenziswa kakhulu kwizinto zodonga lwekhethini, ulwakhiwo lweeshelufu, oololiwe njl.njl. |

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.