Umenzi weNsimbi Q355B C Iprofayili yeNtsimbi eGqityiweyo yeGalvanised Steel U Channel

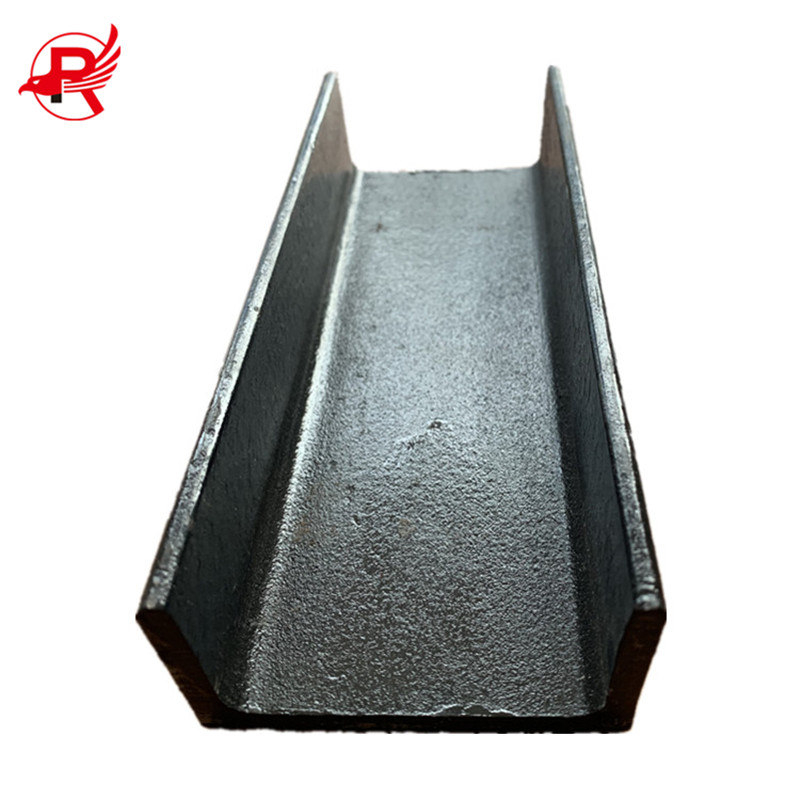

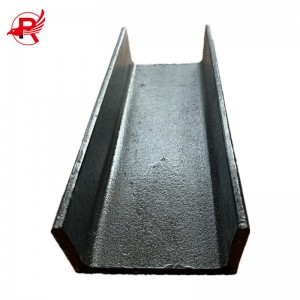

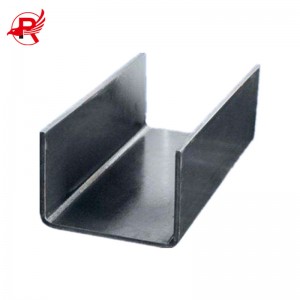

Ifakwe ipleyitiItshaneli ye-C, uhlobo lwentsimbi eqinisiweyo, ibonakaliswa yimo yayo, njengonobumba omkhulu wesiNgesi u-U, ngoko ke ibizwa ngokuba yi-"steel efana no-U".

Intsimbi yeC ChannelIcutshungulwa nge-hot coil kunye ne-cold bending. Inodonga olubhityileyo, ubunzima obulula, ukusebenza kakuhle kwecandelo kunye namandla aphezulu. Xa kuthelekiswa nentsimbi yesitayile sendabuko, inokonga i-30% yezinto ezinamandla afanayo.

Intsimbi enobume buka-U icutshungulwa ngokuzenzekelayo kwaye yenziwe ngumatshini wokwenza intsimbi enobume buka-C. Umatshini wokwenza intsimbi enobume buka-C unokugqiba ngokuzenzekelayo inkqubo yokwenza intsimbi enobume buka-C ngokobungakanani bentsimbi obunikiweyo obunobume buka-C.

Ukuhamba kwenkqubo: ukuthulula—ukulinganisa—ukwakha—ukubumba—ukulungisa—ukulinganisa ubude—ukubhoboza imingxunya engqukuva yeebhari zokubopha—ukubhoboza imingxunya yokudibanisa e-elliptical—ukwakha nokusika.

IIxabiso leChannel yentsimbi egayiweyo ye-Cyahlulwe ngokweemfuno ezintlanu ze-80, 100, 120, 140, kunye ne-160 ngokweemfuno zokuphakama. Ubude bunokuqinisekiswa ngokwendlela yoyilo lobunjineli, kodwa xa kujongwa iimeko zothutho kunye nofakelo, ubude bubonke ngokubanzi abudluli kwiimitha ezili-12.

Intsimbi efakwe u-U, uhlobo lwentsimbi egalelweyo, ibonakaliswa yimo yayo, njengonobumba omkhulu wesiNgesi u-U, ngoko ke ibizwa ngokuba "Itshaneli yentsimbi ye-U".

Intsimbi enomfanekiso we-U icutshungulwa nge-hot coil kunye ne-cold bending. Inodonga olubhityileyo, ubunzima obulula, ukusebenza kakuhle kwecandelo kunye namandla aphezulu. Xa ithelekiswa nentsimbi yesitayile sendabuko, inokonga i-30% yezinto ezinamandla afanayo.

Intsimbi enobume buka-U icutshungulwa ngokuzenzekelayo kwaye yenziwe ngumatshini wokwenza intsimbi enobume buka-C. Umatshini wokwenza intsimbi enobume buka-C unokugqiba ngokuzenzekelayo inkqubo yokwenza intsimbi enobume buka-C ngokobungakanani bentsimbi obunikiweyo obunobume buka-C.

Ukuhamba kwenkqubo: ukuthulula—ukulinganisa—ukwakha—ukubumba—ukulungisa—ukulinganisa ubude—ukubhoboza imingxunya engqukuva yeebhari zokubopha—ukubhoboza imingxunya yokudibanisa e-elliptical—ukwakha nokusika.

Ibha yentsimbi enomfanekiso we-U yahlulwe ngokweemfuno ezintlanu ze-80, 100, 120, 140, kunye ne-160 ngokweemfuno zokuphakama. Ubude bunokuqinisekiswa ngokwendlela yoyilo lobunjineli, kodwa xa kujongwa iimeko zothutho kunye nofakelo, ubude bubonke ngokubanzi abudluli kwiimitha ezili-12.

Iimbonakalo

1. Isitishi se-Uphantsi kwefuthe.

2. Ibeixesha elide lenkxaso

3. Kulula ukuyifaka kwaye akulula ukuyiguqula.

4. Ixabiso eliphantsi kunye nomgangatho olungileyo.

Isicelo

Isetyenziswa kakhulu kwindlela yemigodi, inkxaso yesibini yendlela yemigodi, kunye nenkxaso yemijelo yeentaba kunye nezinye iinjongo.

Njengentsimbi ephambili yokwenza isinyithi esinciphayo endleleni, intsimbi ye-U-section isetyenziswa kakhulu ekhaya nakwamanye amazwe.

Iiparameters

| Igama lemveliso | Itshaneli ye-U |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njl. |

| Uhlobo | Umgangatho we-GB, Umgangatho waseYurophu |

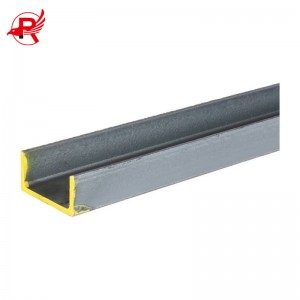

| Ubude | I-Standard 6m kunye ne-12m okanye ngokweemfuno zomthengi |

| Ubuchule | Ishushu Eqengqelekayo |

| Isicelo | Isetyenziswa kakhulu kwizakhiwo ezahlukeneyo, iibhulorho, izithuthi, iibracker, oomatshini njl.njl. |

| Ixesha lokuhlawula | I-L/C, i-T/T okanye i-Western Union |

Iinkcukacha

Dei-livery

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.