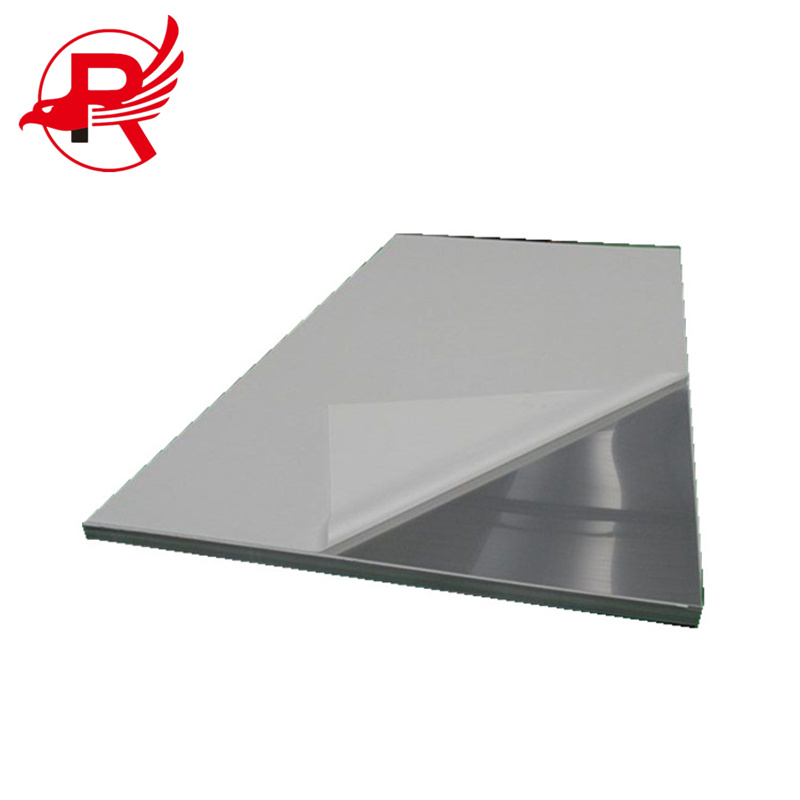

Iphepha lentsimbi yeCarbon eQokelelweyo ePhakamileyo ye-Z275 DX51D Gi Cold Rolled Galvanized Steel Sheet

Ishidi lesinyithiIbhekisa kwishiti yentsimbi egqunywe ngomaleko we-zinc phezu komphezulu. I-Galvanizing yindlela yokuthintela umhlwa engabizi kakhulu nesebenzayo esetyenziswa rhoqo, kwaye malunga nesiqingatha semveliso ye-zinc ehlabathini isetyenziswa kule nkqubo.

Ngokweendlela zokuvelisa kunye nokucubungula, ingahlulwahlulwa ibe ziindidi ezilandelayo:

Iphepha leNtsimbi elisegadini. Nciphisa ipleyiti yesinyithi ebhityileyo kwi-zinc tank etyhidiweyo ukuze wenze ipleyiti yesinyithi ebhityileyo enomaleko we-zinc enamathele kumphezulu wayo. Okwangoku, inkqubo eqhubekayo yokwenza i-galvanizing isetyenziselwa kakhulu ukuvelisa, oko kukuthi, ipleyiti yesinyithi ebhityileyo iqhubeka intywiliselwa kwi-galvanizing tank ene-zinc etyhidiweyo ukwenza ipleyiti yesinyithi etyhidiweyo;

Ipleyiti yentsimbi egalelweyo exutyiweyo. Olu hlobo lwephaneli yentsimbi lwenziwa ngendlela yokuntywila eshushu, kodwa ifudunyezwa ifikelele kuma-500℃ emva nje kokuba iphumile etankini, ukuze yenze ifilimu ye-alloy ye-zinc kunye ne-iron. Le phepha le-galvanized linamathele kakuhle kwipeyinti kwaye liyakwazi ukuwelda;

Ipleyiti yentsimbi egalelwe nge-electro-galvanized. Iphaneli yentsimbi egalelwe nge-electroplating inokulungiswa kakuhle. Nangona kunjalo, ulusu luncinci kwaye ukumelana nokugqwala kwalo akulunganga njengolu lweshiti zegalvini ezishushu

1. Ukumelana nokugqwala, ukupeyinta, ukwakheka kakuhle kunye nokudityaniswa kwamabala.

2. Inoluhlu olubanzi lokusetyenziswa, ikakhulu isetyenziselwa izixhobo zasekhaya ezincinci ezifuna inkangeleko entle, kodwa ibiza kakhulu kune-SECC, ngoko ke abavelisi abaninzi batshintshela kwi-SECC ukuze bonge iindleko.

3. Yahlulwe yizinc: ubungakanani be-span kunye nobukhulu bomaleko wezinc bunokubonisa umgangatho we-galvanizing, okukhona incinci kwaye ityebile kokukhona ingcono. Abavelisi banokongeza unyango oluchasene nokuprintwa kweminwe. Ukongeza, inokwahlulwa ngokugqunywa kwayo, njenge-Z12, oko kuthetha ukuba isixa sisonke sokugqunywa kumacala omabini yi-120g/mm.

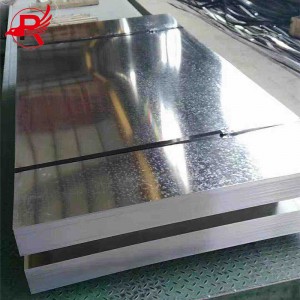

Ipleyiti yentsimbi eshushu egalelweyokwaye iimveliso zentsimbi ezisikiweyo zisetyenziswa kakhulu kumashishini okwakha, amashishini alula, iimoto, ezolimo, ukufuya izilwanyana, ukuloba kunye namashishini orhwebo. Phakathi kwazo, ishishini lokwakha lisetyenziswa kakhulu ukuvelisa iiphaneli zophahla lwezakhiwo zoshishino kunye nezoluntu ezilwa nokugqwala, iigridi zophahla, njl.njl.; ishishini loshishino lokukhanya lisebenzisa lona ukuvelisa amagobolondo ezixhobo zasekhaya, iitshimini zombane, izixhobo zasekhitshini, njl.njl., kwaye ishishini leemoto lisetyenziswa kakhulu ukuvelisa iindawo zeemoto ezingamelani nokugqwala, njl.njl.; Ezolimo, ukufuya izilwanyana kunye nokuloba zisetyenziselwa kakhulu ukugcina nokuthuthwa kweenkozo, inyama ekhenkcezisiweyo kunye neemveliso zasemanzini, njl.njl.; ishishini lisetyenziselwa kakhulu ukugcina nokuthuthwa kwezinto, izixhobo zokupakisha, njl.njl.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.