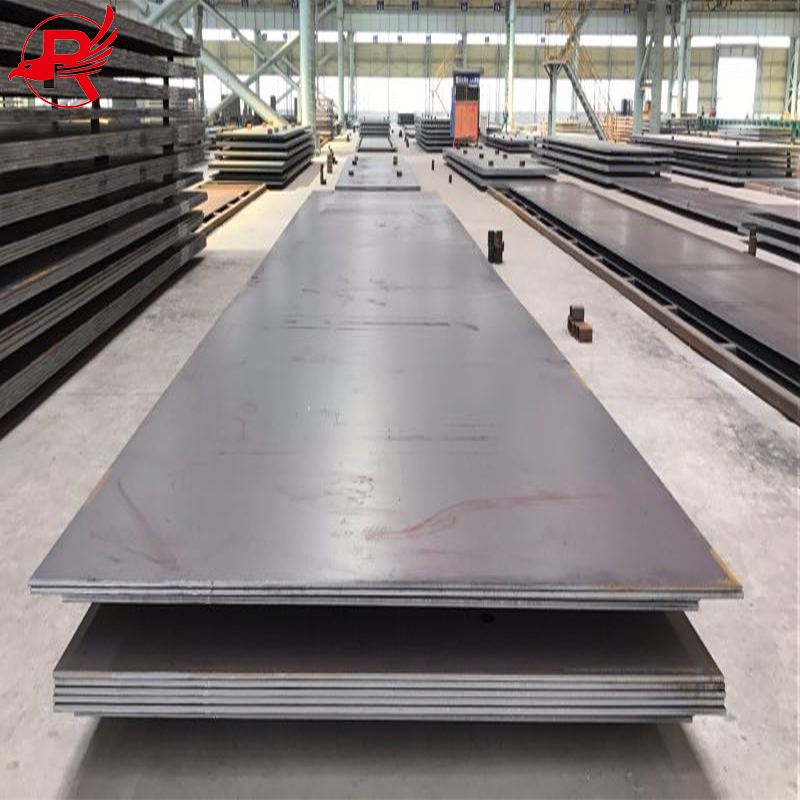

Ipleyiti yentsimbi ye-S235jr eshushu eqengqelekayo emnyama esezantsi ene-Wear Resistant

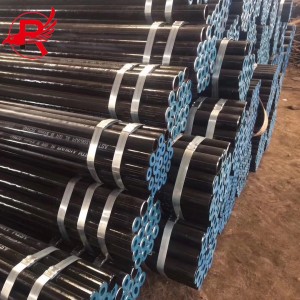

| Igama lemveliso | Ukuthengisa Okushushu Okusemgangathweni OphezuluIshiti yentsimbi eshushu eqengqelekayo |

| Izinto eziphathekayo | 10#, 20#, 45#, 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42, St37-2, St35.4, St52.4, ST35 |

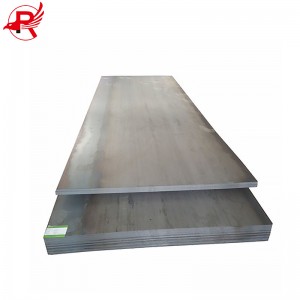

| Ubukhulu | 1.5mm ~ 24mm |

| Ubungakanani | 3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm eyenziwe ngokwezifiso |

| Umgangatho | I-ASTM A53-2007, i-ASTM A671-2006, i-ASTM A252-1998, i-ASTM A450-1996, i-ASME B36.10M-2004, i-ASTM A523-1996, i-BS 1387, i-BS EN10296, i-BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

| Ibanga | A53-A369, Q195-Q345, ST35-ST52 |

| Ibanga A, Ibanga B, Ibanga C | |

| Ubuchule | Ishushu iqengqelekile |

| Ukupakisha | Iphakheji, okanye eneentlobo ngeentlobo zemibala yePVC okanye ngokweemfuno zakho |

| Iziphelo zePipe | Isiphelo esicacileyo/Esibekiweyo, esikhuselwe ziiplastiki eziphezu zombini, isikwere esisikiweyo, esigobileyo, esifakwe imisonto kunye nesiqhagamshelo, njl. |

| I-MOQ | Iitoni ezi-1, ixabiso elingaphezulu lobuninzi liya kuba phantsi |

| Unyango Lomphezulu | 1. Igqityiwe i-mill / I-galvanized / intsimbi engatyiwayo |

| 2. Ipeyinti yePVC, emnyama nombala | |

| 3. Ioyile ecacileyo, ioyile yokulwa nomhlwa | |

| 4. Ngokweemfuno zabathengi | |

| Isicelo seMveliso |

|

| Imvelaphi | Tianjin China |

| Izatifikethi | ISO9001-2008, SGS.BV, TUV |

| Ixesha lokuzisa | Ngokwesiqhelo zingakapheli iintsuku ezisi-7-10 emva kokufumana intlawulo kwangaphambili |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Ukusetyenziswa kwePlate yeNsimbi eShushu eRoliwe

1. Intsimi yokwakha: Iipleyiti zentsimbi eziqengqelekayo zisetyenziswa rhoqo ekuxhaseni, phantsi, kwiiphaneli zodonga nakwiiphahla zezakhiwo zokwakha, kuquka izakhiwo ezinkulu ezifana neebhulorho kunye nezakhiwo eziphakamileyo.

2. Intsimi yokwenziwa kweemoto: amaphepha entsimbi atshisiweyo athatha indawo ebalulekileyo kwinkqubo yokwenziwa kweemoto, kwaye ukusetyenziswa kwawo okuphambili kukwenza izakhiwo zomzimba, iingcango, iikhava kunye nezinye izinto.

3. Intsimi yamandla: iipleyiti zentsimbi eziqengqelekayo ezishushu zisetyenziselwa ukuvelisa izixhobo zamandla ezifana nezityalo zamandla, iinqaba zothumelo kunye nemibhobho yeoyile.

4. Kwicandelo lokwenziwa koomatshini: iipleyiti zentsimbi ezigoqwe ngobushushu zingasetyenziselwa ukuvelisa izixhobo zoomatshini, iirobhothi kunye nezinye izixhobo zoshishino.

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Ukuqengqeleka okushushu yinkqubo yokugaya equka ukuqengqeleka kwentsimbi kubushushu obuphezulu

ephezu kwentsimbiubushushu bokuphinda kusetyenziswe icrystallization.

Ukupakisha ngokubanzi akunanto, kubopha ucingo lwentsimbi, kuqinile kakhulu.

Ukuba uneemfuno ezikhethekileyo, ungasebenzisa ukupakisha okungenamhlwa, kwaye ube mhle ngakumbi.

Umda wobunzima bepleyiti yentsimbi

Ngenxa yobuninzi nobunzima beepleyiti zentsimbi, iimodeli zezithuthi ezifanelekileyo kunye neendlela zokulayisha kufuneka zikhethwe ngokweemeko ezithile ngexesha lokuthuthwa. Kwiimeko eziqhelekileyo, iipleyiti zentsimbi ziya kuthuthwa ngeelori ezinzima. Izithuthi zothutho kunye nezixhobo kufuneka zihambelane nemigangatho yokhuseleko lwesizwe, kwaye kufunyanwe izatifikethi ezifanelekileyo zokufaneleka kwezothutho.

2. Iimfuneko zokupakisha

Kwiipleyiti zentsimbi, ukupakishwa kubaluleke kakhulu. Ngexesha lenkqubo yokupakishwa, umphezulu wepleyiti yentsimbi kufuneka uhlolwe ngononophelo ukuze kujongwe umonakalo omncinci. Ukuba kukho nawuphi na umonakalo, kufuneka ulungiswe kwaye uqiniswe. Ukongeza, ukuqinisekisa umgangatho kunye nembonakalo yemveliso iyonke, kuyacetyiswa ukusebenzisa izigqubuthelo zepleyiti yentsimbi yobungcali ekupakishweni ukuze kuthintelwe ukuguguleka kunye nokufuma okubangelwa kukuhamba.

3. Ukukhetha indlela

Ukukhetha indlela yingxaki ebaluleke kakhulu. Xa uthutha iipleyiti zentsimbi, kufuneka ukhethe indlela ekhuselekileyo, ezolileyo negudileyo kangangoko unako. Kufuneka uzame konke okusemandleni akho ukuphepha iindawo eziyingozi zendlela ezifana neendlela ezisecaleni kunye neendlela zeentaba ukuze uphephe ukulahlekelwa lulawulo lwelori nokuguqa nokubangela umonakalo omkhulu kwimpahla.

4. Cwangcisa ixesha ngokufanelekileyo

Xa kuthuthwa iipleyiti zentsimbi, kufuneka kulungiselelwe ixesha elifanelekileyo kwaye kugcinwe ixesha elaneleyo lokujongana neemeko ezahlukeneyo ezinokuvela. Nanini na xa kunokwenzeka, kufuneka kuthuthwe ngexesha elingengomsebenzi uwonke ukuqinisekisa ukusebenza kakuhle kwezothutho kunye nokunciphisa uxinzelelo lwendlela.

5. Nika ingqalelo kukhuseleko

Xa kuthuthwa iipleyiti zentsimbi, kufuneka kuqwalaselwe imiba yokhuseleko, njengokusebenzisa amabhanti okhuseleko, ukujonga imeko yezithuthi ngexesha elifanelekileyo, ukugcina imeko yendlela icacile, kunye nokubonelela ngezilumkiso ngexesha elifanelekileyo kwiindawo ezinobungozi zendlela.

Ngamafutshane, zininzi izinto ekufuneka ziqwalaselwe xa kuthuthwa iipleyiti zentsimbi. Kufuneka kuqwalaselwe ngokubanzi imiqathango yobunzima beepleyiti zentsimbi, iimfuno zokupakisha, ukukhethwa kwendlela, amalungiselelo exesha, iziqinisekiso zokhuseleko kunye nezinye izinto ukuqinisekisa ukuba ukhuseleko lwemithwalo kunye nokusebenza kakuhle kokuthutha kuphuculwa ngexesha lenkqubo yokuthutha. Imeko engcono kakhulu.

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.