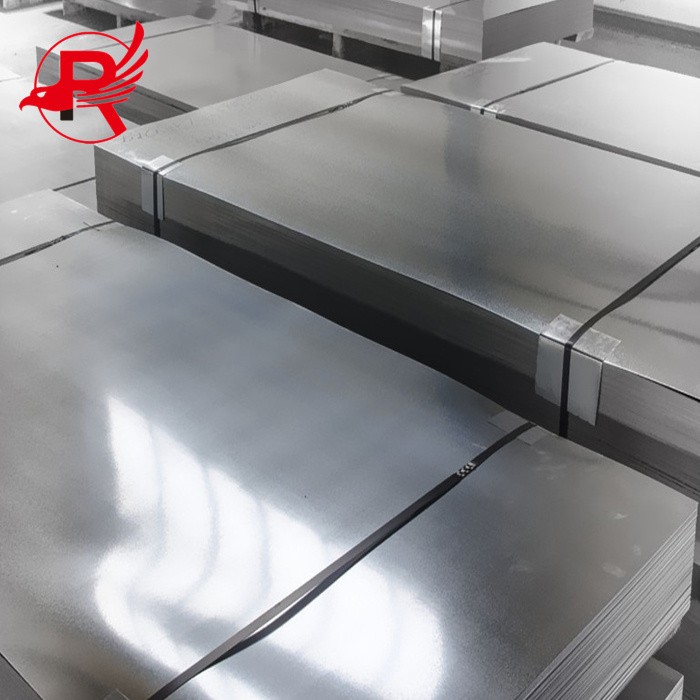

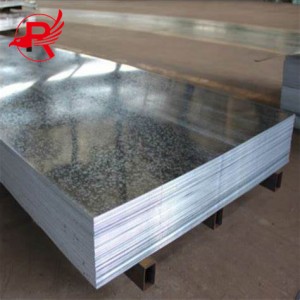

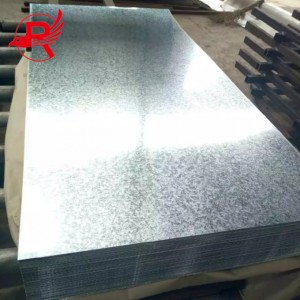

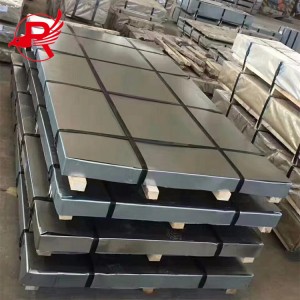

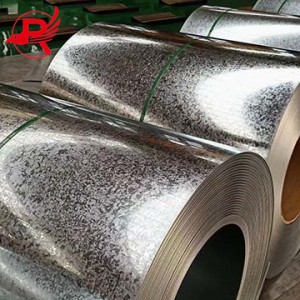

Izixhobo zokwakha ezikumgangatho ophezulu ze-0.12-4.0mm SPCC Cold Rolled Galvanized Steel Sheet

Kukho iinkcukacha ezithile ekufuneka ziqwalaselwe xa kusetyenziswa amaphepha e-galvanized. Okokuqala, ngexesha lokuthuthwa nokugcinwa, kufuneka kuthintelwe ukungqubana nokungqubana ukuze kuthintelwe ukonakala komaleko we-galvanized. Okwesibini, ngexesha lokufakwa nokucutshungulwa, kufuneka kukhethwe izixhobo kunye neendlela ezifanelekileyo ukuze kuthintelwe ukukrwela nokonakalisa umaleko we-galvanized. Ukongeza, ngexesha lokusetyenziswa, amaphepha e-galvanized kufuneka acocwe kwaye agcinwe rhoqo, kwaye ukungcola kunye nokungcola okukumphezulu kufuneka kususwe ngexesha ukuze kugcinwe imbonakalo kunye nokusebenza kakuhle. Ukongeza, kufuneka kuthathelwe ingqalelo ukuphepha ukudibana neekhemikhali ezifana nee-asidi kunye nee-alkali ukuze kuthintelwe ukuxhathisa kokugqwala kwamaphepha e-galvanized. Okokugqibela, kufuneka kuthathelwe ingqalelo ukuphepha ukusetyenziswa kwiindawo ezinobushushu obuphezulu ukuze kuthintelwe ukuchaphazela ukusebenza komaleko we-galvanized. Ngokubanzi, ukusetyenziswa ngokuchanekileyo kunye nokugcinwa ngundoqo ekuqinisekiseni ukusebenza okuzinzileyo kwexesha elide kwamaphepha e-galvanized. Ukusetyenziswa ngokufanelekileyo kunye nokugcinwa kunokwandisa ubomi benkonzo yamaphepha e-galvanized kwaye kuqinisekiswe iziphumo zokusetyenziswa kwawo kwiindawo ezahlukeneyo.

Ishidi lesinyithizinezibonelelo ezininzi ezenza ukuba zisetyenziswe kakhulu kwiindawo ezahlukeneyo. Okokuqala, amaphepha e-galvanized anokumelana nokugqwala okuhle kakhulu. Umaleko we-galvanized unokuthintela ngempumelelo umphezulu wentsimbi ekubeni ungcoliswe ngumoya, amanzi kunye nezinto zeekhemikhali, ngaloo ndlela wandise ubomi benkonzo yentsimbi. Okwesibini, amaphepha e-galvanized anokumelana nokugqwala okuhle kwaye afanelekile kwiindawo ezifuna ukumelana nokungqubana nokugqwala, njengezakhiwo zokwakha, izixhobo zoomatshini kunye nezinye iindawo. Ukongeza,Ipleyiti yentsimbi eshushu egalelweyozikwanazo neempawu ezilungileyo zokucubungula kwaye zinokucutshungulwa ngokugoba, ukunyathela, ukuwelda, njl.njl., kwaye zifanelekile ukuvelisa iimilo ezahlukeneyo ezintsonkothileyo. Ukongeza, umphezuluIphepha leNtsimbi elisegadiniigudile kwaye intle, kwaye ingasetyenziswa ngokuthe ngqo njengezinto zokuhombisa. Ukongeza, amaphepha e-galvanized akwanayo ne-conductivity entle yombane kwaye afanelekile kumandla ombane, unxibelelwano kunye nezinye iindawo. Ngokubanzi, amaphepha e-galvanized abe yenye yezinto eziyimfuneko ekwakheni, koomatshini, kumbane, kunxibelelwano nakwezinye iindawo ngenxa yokumelana nokugqwala, ukumelana nokuguguleka kunye nokusebenza kakuhle kokucubungula.

Ipleyiti yentsimbi egalelweyozisetyenziswa kakhulu kwiindawo ezahlukeneyo. Okokuqala, kwicandelo lokwakha, amaphepha e-galvanized adla ngokusetyenziswa kwiinkqubo zokuxhasa kunye nokukhuculula amanzi kwizakhiwo zokwakha. Ingasetyenziswa kwizakhelo zokwakha, ii-handrails zezitebhisi, ii-railings kunye nezinye izinto, kwaye ingasetyenziswa njengezinto eziphambili zemibhobho yokukhupha amanzi kuba ukumelana kwayo nokukhuculula kunokwandisa ubomi bayo benkonzo. Okwesibini, kwicandelo lemizi-mveliso, amaphepha e-galvanized adla ngokusetyenziswa ukwenza izixhobo ezahlukeneyo kunye nezinto, ezifana neetanki zokugcina, iipayipi, iifeni, izixhobo zokuhambisa, njl. Ukumelana nokukhuculula kwamaphepha e-galvanized kwenza ukuba kusetyenziswe ixesha elide kwiindawo zoshishino ezinzima, ukuqinisekisa ukusebenza ngokukhuselekileyo kwezixhobo. Ukongeza, kwicandelo lezolimo, amaphepha e-galvanized nawo anezicelo ezibalulekileyo. Ingasetyenziswa kwiinkqubo zokunkcenkceshela zasefama, izakhiwo zokuxhasa oomatshini bezolimo, njl. kuba ukumelana kwayo nokukhuculula kunokumelana nokukhuculula kwezixhobo ziikhemikhali emhlabeni. Ukongeza, kwicandelo lothutho, amaphepha e-galvanized adla ngokusetyenziswa ukuvelisa iindawo zeemoto, izinto zeenqanawa, njl., kuba ukumelana kwazo nokukhuculula kunokwandisa ubomi benkonzo yezithuthi zothutho. Ngokubanzi, amaphepha e-galvanized anezicelo ezibalulekileyo kulwakhiwo, kushishino, kwezolimo, kwezothutho nakwezinye iindawo, kwaye ukumelana kwawo nokugqwala kuwenza abe yenye yezona zinto zifanelekileyo kwizixhobo ezahlukeneyo kunye nezakhiwo.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.