Iipayipi zeGi zePipe zeSteel zeDIP ezishushu

Njengesixhobo sepayipi yesinyithi esibalaseleyo, ipayipi ye-galvanized inamathuba amaninzi okusetyenziswa. Xa isetyenziswa ngokwenene, uhlobo olufanelekileyo kunye neenkcukacha zepayipi ye-galvanized kufuneka zikhethwe ngokwemeko ethile, kwaye zifakwe kwaye zigcinwe ngokuhambelana nemigangatho kunye neenkcukacha ezifanelekileyo ukuqinisekisa ukusebenza okukhuselekileyo nokuzinzileyo kwepayipi.

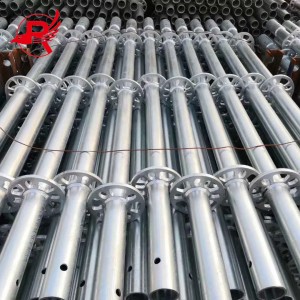

Iimbonakalo

Eyona nto ibalulekileyo ngepayipi egalelweyo kukusebenza kwayo okuhle kakhulu ekulweni nokugqwala. Ukubakho komaleko we-zinc kuyawususa umbhobho wentsimbi ekudibaneni nehlabathi langaphandle kwaye kuthintela ukubola kunye nokugqwala kombhobho wentsimbi. Le mpawu yenza umbhobho ogalelweyo uzinze kwiindawo ezahlukeneyo zokugqwala.

Isicelo

Umbhobho we-galvanized uqinile kakuhle ngenxa yokukhuselwa komaleko we-zinc. Nokuba phantsi kweemeko ezinzima zokusingqongileyo, ezinje ngokufuma, ubushushu obuphezulu, ubushushu obuphantsi, njl.njl., imibhobho ye-galvanized ingagcina ukusebenza kwayo kwasekuqaleni kunye nembonakalo yayo.

Iiparameters

| Igama lemveliso | Umbhobho wesinyithi |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njl. |

| Ubude | I-Standard 6m kunye ne-12m okanye ngokweemfuno zomthengi |

| Ububanzi | 600mm-1500mm, ngokweemfuno zomthengi |

| Ezobugcisa | Ishushu Ityiwe Ngesinyithiumbhobho |

| Ukwaleka kweZinc | 30-275g/m2 |

| Isicelo | Isetyenziswa kakhulu kwizakhiwo ezahlukeneyo, iibhulorho, izithuthi, iibracker, oomatshini njl.njl. |

Iinkcukacha

Iileya zeZinc zingaveliswa ukusuka kwi-30g ukuya kwi-550g kwaye zingabonelelwa nge-hotdip galvanizing, i-electric galvanizing kunye ne-pre-galvanizing. Zibonelela ngomaleko wenkxaso yemveliso ye-zinc emva kwengxelo yokuhlolwa. Ubukhulu benziwa ngokuhambelana nesivumelwano. Inkqubo yenkampani yethu ukunyamezelana kobukhulu kungaphakathi kwe-±0.01mm. Iileya zeZinc zingaveliswa ukusuka kwi-30g ukuya kwi-550g kwaye zingabonelelwa nge-hotdip galvanizing, i-electric galvanizing kunye ne-galvanizing. Zibonelela ngomaleko wenkxaso yemveliso ye-zinc emva kwengxelo yokuhlolwa. Ubukhulu benziwa ngokuhambelana nesivumelwano. Inkqubo yenkampani yethu ukunyamezelana kobukhulu kungaphakathi kwe-±0.01mm. I-laser cutting nozzle, i-nozzle igudile kwaye icocekile. Umbhobho othe tye othungelweyo, umphezulu we-galvanized. Ubude obunqumla ukusuka kwi-6-12meters, singabonelela ngobude obuqhelekileyo baseMelika obuyi-20ft 40ft. Okanye singavula i-mold ukuze senze ngokwezifiso ubude bemveliso, njenge-13 metres ect. 50.000m warehouse. Ivelisa ngaphezu Iitoni ezingama-5,000 zeempahla ngosuku. Ukuze sikwazi ukuzinika ixesha lokuthumela ngokukhawuleza kunye namaxabiso afanelekileyo.

Umbhobho we-galvanized sisixhobo sokwakha esiqhelekileyo kwaye sisetyenziswa ngeendlela ezahlukeneyo. Kwinkqubo yokuthunyelwa, ngenxa yempembelelo yeemeko zokusingqongileyo, kulula ukubangela iingxaki ezifana nokugqwala, ukuguquka okanye umonakalo kumbhobho wentsimbi, ngoko ke kubaluleke kakhulu ekupakishweni nasekuthuthweni kwemibhobho ye-galvanized. Eli phepha liza kwazisa indlela yokupakisha umbhobho we-galvanized kwinkqubo yokuthunyelwa.

2. Iimfuneko zokupakisha

1. Umphezulu wombhobho wentsimbi kufuneka ucoceke kwaye wome, kwaye akufuneki kubekho amafutha, uthuli kunye nezinye izinto ezimdaka.

2. Umbhobho wentsimbi kufuneka upakishwe ngephepha leplastiki elinomgangatho ophindwe kabini, umaleko ongaphandle ugqunywe ngephepha leplastiki elinobukhulu obungaphantsi kwe-0.5mm, kwaye umaleko ongaphakathi ugqunywe ngefilimu yeplastiki yepolyethylene ecacileyo enobukhulu obungaphantsi kwe-0.02mm.

3. Umbhobho wentsimbi kufuneka uphawulwe emva kokupakishwa, kwaye uphawu kufuneka lubandakanye uhlobo, iinkcukacha, inombolo yebhetshi kunye nomhla wokuveliswa kombhobho wentsimbi.

4. Umbhobho wentsimbi kufuneka uhlelwe kwaye upakishwe ngokweendidi ezahlukeneyo ezifana neenkcukacha, ubungakanani kunye nobude ukuze kube lula ukulayisha nokukhupha impahla kunye nokugcina impahla.

Okwesithathu, indlela yokupakisha

1. Ngaphambi kokuba upakishe umbhobho we-galvanized, umphezulu wombhobho kufuneka ucocwe kwaye uphathwe ukuqinisekisa ukuba umphezulu ucocekile kwaye womile, ukuze kuthintelwe iingxaki ezinje ngokugqwala kombhobho wentsimbi ngexesha lokuthunyelwa.

2. Xa kupakishwa imibhobho ye-galvanized, kufuneka kuqwalaselwe ukukhuselwa kwemibhobho yentsimbi, kunye nokusetyenziswa kwe-red cork splints ukuqinisa zombini iziphelo zemibhobho yentsimbi ukuthintela ukuguquka nokonakala ngexesha lokupakisha nokuthuthwa.

3. Izinto zokupakisha zepayipi egalelweyo mazibe nefuthe lokungafumi, ukungangeni manzi kunye nokungagqwali ukuqinisekisa ukuba ipayipi yentsimbi ayichaphazeleki kukufuma okanye ukugqwala ngexesha lenkqubo yokuthumela.

4. Emva kokuba umbhobho we-galvanized upakishiwe, qaphela izinto ezingangenisi manzi kunye ne-sunscreen ukuze uphephe ukuvezwa lilanga ixesha elide okanye kwindawo efumileyo.

4. Amanyathelo okuzikhusela

1. Ukupakisha imibhobho egalelwe nge-galvanized kufuneka kuthathelwe ingqalelo ekumiselweni kobukhulu nobude ukuze kuthintelwe inkunkuma kunye nokulahleka okubangelwa kukungalingani kobukhulu.

2. Emva kokupakishwa kombhobho we-galvanized, kuyimfuneko ukuwuphawula nokuwuhlela ngexesha elifanelekileyo ukuze kube lula ukulawula kunye nokugcinwa kwempahla.

3, ukupakishwa kwemibhobho egalelwe nge-galvanized, kufuneka kuqwalaselwe ukuphakama nokuzinza kweempahla ezibekwe ngokweemfuno, ukuze kuthintelwe ukuthambekela kweempahla okanye ukubekeka ngokweemfuno phezulu kakhulu ukuze kungonakalisa iimpahla.

Le ingentla yindlela yokupakisha ipayipi egqunyiweyo kwinkqubo yokuthumela, kuquka iimfuno zokupakisha, iindlela zokupakisha kunye namanyathelo okhuseleko. Xa upakisha kwaye uthutha, kuyimfuneko ukusebenza ngokungqongqo ngokwemigaqo, kwaye ukhusele ngokufanelekileyo ipayipi yentsimbi ukuqinisekisa ukufika ngokukhuselekileyo kwempahla kwindawo oya kuyo.

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.