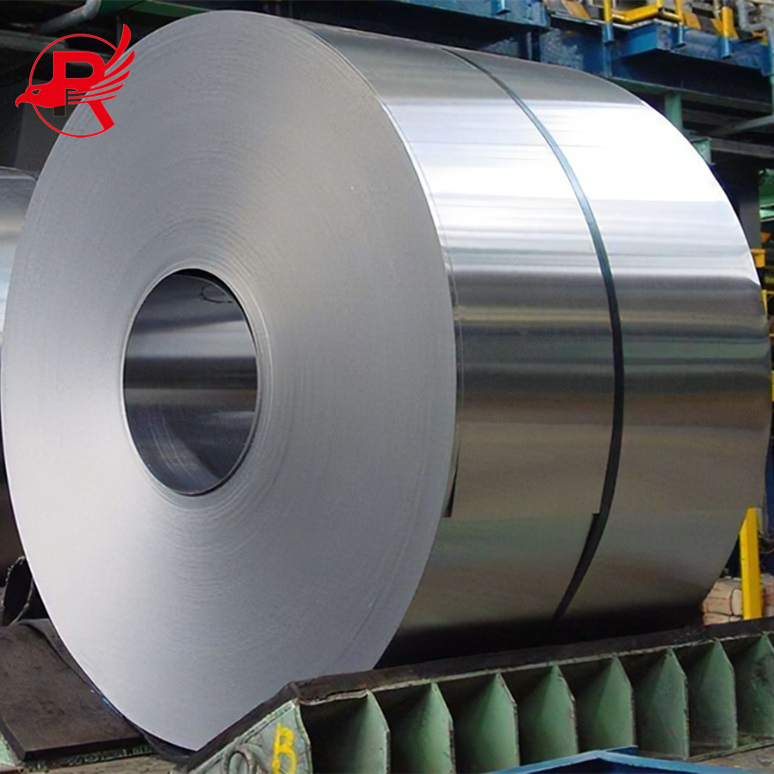

I-Hot Rolled Aisi 309 310 310S 321 Stainless Steel Coil

| Igama lemveliso | Ikhoyili yentsimbi engagqwaliyo engu-309 310 310S 321 |

| Amabanga | 201/EN 1.4372/SUS201 |

| Ukuqina | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Umngxuma/Isigayo |

| Ukunyamezela Ubungakanani | ± 10% |

| Ububanzi bangaphakathi beCore yePhepha | Isiseko sephepha se-Ø500mm, isiseko esikhethekileyo sobubanzi bangaphakathi kwaye ngaphandle kwesiseko sephepha xa umthengi ecela |

| Umphezulu wokugqiba | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njl.njl. |

| Ukupakisha | Ipallet yomthi/Ityala lomthi |

| Immimiselo yokuhlawula | Idiphozithi ye-30% TT kunye nebhalansi ye-70% ngaphambi kokuthunyelwa, i-100% LC ibonwa |

| Ixesha lokuzisa | Iintsuku zokusebenza ezisi-7-15 |

| I-MOQ | 200Kgs |

| Izibuko lokuThumela | Izibuko laseShanghai/Ningbo |

| Isampulu | Isampulu ye-309 310 310S 321 coil yentsimbi engagqwali iyafumaneka |

I-201 yintsimbi engenasici enomphunga ophantsi enika ukudityaniswa okuhle kakhulu, ukumelana nokugqwala okuhle kunye namandla aphezulu. Yinto efanelekileyo kwizicelo ezahlukeneyo kubandakanya izixhobo zokulungisa ukutya kunye nezixhobo zokulungisa iikhemikhali.

Olu luhlu lulandelayo lwezinye zezona zicelo zixhaphakileyo zeekhoyili zentsimbi engagqwaliyo:

1. Izixhobo Zokucubungula Ukutya kunye Nezixhobo Zokucubungula Iikhemikhali

2. Amashishini eoyile negesi

3. Izicelo zaseLwandle

Phawula:

1. Isampuli yasimahla, isiqinisekiso somgangatho emva kokuthengisa esiyi-100%, Xhasa nayiphi na indlela yokuhlawula;

2. Zonke ezinye iinkcukacha zeepayipi zentsimbi yekhabhoni ezijikelezayo ziyafumaneka ngokweemfuno zakho (OEM & ODM)! Ixabiso lefektri uza kulifumana kwi-ROYAL GROUP.

Iinxalenye zeekhemikhali zekhoyili yentsimbi engagqwaliyo

| Ulwakhiwo lweeKhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa iindlela ezahlukeneyo zokucubungula ukuqengqeleka okubandayo kunye nokuphinda kusetyenzwe umphezulu emva kokuqengqeleka, ukugqitywa komphezulu weekhoyili zentsimbi engagqwaliyo kunokuba neentlobo ezahlukeneyo.

Intsimbi engagqwaliyo yinto eguquguqukayo nehlala ixesha elide esetyenziswa kwiintlobo ngeentlobo zezicelo, ukusuka kwizitya zasekhitshini ukuya kwizinto zokwakha. Iintsimbi ezingagqwaliyo ziyinxalenye ebalulekileyo yeemveliso ezininzi njengoko zibonelela ngendlela yokwenza le nto ibe yimilo kunye nobukhulu obuthile. Makhe sijonge ngokusondeleyo inkqubo yokuvelisa iintsimbi ezingagqwaliyo.

1. Ukunyibilikisa nokucokisa: Inyathelo lokuqala kwinkqubo yemveliso kukunyibilikisa izinto ezisetyenziswa ekwenzeni intsimbi engagqwaliyo—ngokuqhelekileyo i-iron ore, i-nickel, i-chromium, kunye nezinye iintsimbi. Oku kwenziwa kwi-oven okanye kwi-oven, ngokuqhelekileyo kusetyenziswa i-electric arc okanye i-induction furnace. Isinyithi esinyibilikisiweyo esiphumayo siyacocwa ukuze kususwe ukungcola nokuqinisekisa ukwakheka okufanelekileyo kwe-alloy.

2. Ukuphosa: Emva kokuba isinyithi sicociwe, sigalelwa kwiimolds ukuze senze ii-billets eziphosiweyo. Islab inokuba nobukhulu obuziisentimitha ezimbalwa kwaye ibe nobunzima obuziitoni ezingama-20 nangaphezulu. Le nkqubo yokuphosa idla ngokwenziwa kumatshini wokuphosa oqhubekayo, oqinisekisa ukuhamba rhoqo kwezinto kunye nokusebenza kakuhle okukhulu.

3. Ukuqengqeleka okushushu: Emva koko i-slab iyafudunyezwa ize idlule kuthotho lwee-hot rolling mills. Ii-rolling mills zixhotyiswe ngee-rolls ezicinezela kwaye zenze intsimbi ibe ngamaphepha amancinci okanye imicu. Inkqubo yokuqengqeleka okushushu inokuvelisa amaqondo obushushu angaphezu kwe-1,000 degrees Celsius, nto leyo evumela ukuba izinto zenziwe ngendlela engaqhelekanga ngaphandle kokuqhekeka.

4. Ukuqengqeleka okubandayo: Emva kokuba inkqubo yokuqengqeleka okushushu igqityiwe, intsimbi engagqwaliyo iyaqengqeleka ebandayo ukuze kufikelelwe kubukhulu obufunekayo kunye nokugqitywa komphezulu. Oku kubandakanya ukudlulisa izinto kuthotho lweemill zokuqengqeleka ezibandayo, ezicinezela kwaye zenze intsimbi ibe yiyo ngakumbi. Ukuqengqeleka okubandayo kwandisa amandla kunye nokuqina kwentsimbi engagqwaliyo, okwenza ukuba iqine ngakumbi kwaye ihlale ixesha elide.

5. Ukuqhoboshela: Nje ukuba intsimbi engagqwaliyo iqengqelwe ukuya kubukhulu obufunekayo, emva koko iyaqhoboshelwa ngexesha lonyango lobushushu. Oku kubandakanya ukufudumeza loo nto ukuya kubushushu obuphezulu uze uyipholise kancinci ngokuhamba kwexesha. Ukuqhoboshela kunceda ukuthambisa intsimbi engagqwaliyo kwaye kwandisa ukuguguleka kwayo, okwenza kube lula ukwenza iikhoyili okanye ezinye iimilo.

6. Ukusikwa nokujijelwa: Okokugqibela, intsimbi engagqwaliyo yahlulwe yaba yimicu—isikwe yaba yimicu emincinci—ize ijijelwe ukuze ithunyelwe kwaye igcinwe. Le nkqubo idla ngokwenziwa kusetyenziswa izixhobo ezikhethekileyo ezifana nezilayidi kunye neekhoyili. Ikhoyili ingathunyelwa kumenzi okanye umenzi oza kusebenzisa loo nto ukwenza imveliso egqityiweyo.

upakisho oluqhelekileyo lolwandle lwekhoyili yentsimbi engagqwaliyo

Ukupakisha okuqhelekileyo kolwandle oluthunyelwa ngaphandle:

Iphepha elingangeni manzi eliyi-Winding + i-PVC Film + i-Strap Banding + i-Wooden Pallet okanye i-Wooden Case;

Ukupakisha okwenziwe ngokwezifiso ngokwesicelo sakho (Ilogo okanye ezinye izinto eziqulathweyo ziyavunywa ukuba ziprintwe kwiphakheji);

Ezinye izinto ezikhethekileyo zokupakisha ziya kuyilwa ngokwesicelo somthengi;

Uthutho:Ukuhanjiswa ngokukhawuleza (Ukuhanjiswa kwesampuli), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (i-FCL okanye i-LCL okanye iBulk)

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.