Intengiso Eshushu DX51D Z275 Zinc Coated Cold Rolled Hot Dipped Galvanized Steel Coil

Ikhoyili egalelwe ngesinyithi,

Intsimbi egayiweyo luhlobo lwentsimbi egqunywe nge-zinc ukuthintela ukugqwala. Iintsimbi ezigayiweyo zenziwe ngeentsimbi ezisemgangathweni ophezulu kwaye zicutshungulwa nge-hot-dip galvanizing eqhubekayo.

Inkqubo yokufaka i-galvanizing ibandakanya ukuntywilisela umcu wentsimbi kwisitya se-zinc enyibilikisiweyo. Umaleko we-zinc unamathela ngokuqinileyo kumphezulu wentsimbi ukuze umelane nokugqwala kakuhle kwaye uhlale ixesha elide. Ubukhulu bomaleko we-galvanizing bunokwahluka ngokuxhomekeke ekusetyenzisweni kwe-coil yentsimbi ye-galvanizing.

Nazi ezinye iinkcukacha ezibalulekileyo malungaIkhoyili yentsimbi egalelweyo:

-Ikhoyili yeGIezinobukhulu nobubanzi obahlukeneyo zingenziwa ngokweemfuno zabathengi.

- Iikhoyili zentsimbi ezigayiweyo zinokwenziwa kwiindidi ezahlukeneyo zentsimbi ezifana nentsimbi ye-high strength low alloy (HSLA), intsimbi yekhabhoni kunye nentsimbi engagqwaliyo.

- Iikhoyili zentsimbi ezigayiweyo zisetyenziswa kwiintlobo ngeentlobo zezicelo kuquka iimoto, ezokwakha, ezemizi-mveliso kunye nezezolimo.

- Ikhoyili yentsimbi egayiweyo inokwakheka kakuhle, iyakwazi ukudityaniswa kwaye iyakwazi ukupeyintwa, nto leyo eyenza ukuba ibe yinto esebenziseka lula kwiintlobo ngeentlobo zezicelo.

- Iikhoyili zentsimbi ezigayiweyo zingapeyintwa kwangaphambili okanye zigqunywe ngokongeza ukuze kuphuculwe ukusebenza kwazo kwizicelo ezithile.

- Iikhoyili zentsimbi ezigayiweyo ziyindlela engabizi kakhulu nezinzileyo kumashishini amaninzi njengoko zinobomi obude benkonzo kwaye zinokuphinda zisetyenziswe ekupheleni kobomi bazo obuluncedo.

1. Ukumelana Nokugqwala: I-Galvanizing yindlela yokuthintela ukugqwala engabizi kakhulu nesebenzayo esetyenziswa rhoqo. Malunga nesiqingatha semveliso ye-zinc yehlabathi isetyenziselwa le nkqubo. I-Zinc ayenzi nje kuphela umaleko okhuselekileyo kumphezulu wentsimbi, kodwa ikwanomphumo wokukhusela i-cathodic. Xa i-zinc coating yonakele, isenokuthintela ukugqwala kwezinto ezisekwe kwisinyithi ngokukhusela i-cathodic.

2. Ukusebenza kakuhle kokugoba nokubanda kunye nokuwelda: kusetyenziswa kakhulu intsimbi enekhabhoni ephantsi, nto leyo efuna ukugoba kakuhle nokubanda, ukusebenza kakuhle kokuwelda kunye nokusebenza okuthile kokunyathela

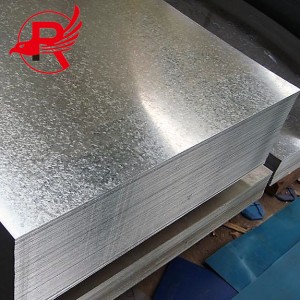

3. Ukukhanya okubonakalayo: ukukhanya okuphezulu, okwenza kube ngumqobo wobushushu

4. Ingubo Iqinile Kakhulu, kwaye ingubo ye-zinc yenza isakhiwo esikhethekileyo se-metallurgical, esinokumelana nomonakalo woomatshini ngexesha lokuthuthwa nokusetyenziswa.

Iikhoyili zentsimbi ezigayiweyozisetyenziswa kakhulu kwizicelo ezahlukeneyo kumashishini ahlukeneyo. Nazi ezinye zezicelo eziqhelekileyo zee-GI coils:

1. Ulwakhiwo: Iikhoyili zentsimbi ezigayiweyo zisetyenziswa kakhulu kwishishini lokwakha ukwenza uphahla, iindonga, iingcango, iifestile kunye nezinye izinto zokwakha. Ingubo egayiweyo inokumelana nokugqwala okugqwesileyo, nto leyo eyenza ukuba ibe yinto efanelekileyo yokusetyenziswa ngaphandle.

2. Iimoto: Iikhoyili ze-GI zisetyenziswa kwishishini leemoto ukwenza izinto ezahlukeneyo ezifana neephaneli zomzimba, iifreyimu, kunye ne-chassis. Amandla ayo kunye nokumelana nokugqwala kwenza ukuba ilungele ezi zicelo.

3. Zombane: Iikhoyili ze-GI zikwasetyenziswa kwishishini lombane ekwenzeni i-switchgear, iiphaneli zolawulo kunye nee-conduits. I-galvanized coating inika ukumelana nokugqwala kunye ne-oxidation kwaye ikwaphucula ukuhanjiswa kombane.

4. Ezolimo: Iintsimbi zentsimbi ezifakwe i-galvanized zihlala zisetyenziswa kwishishini lezolimo ekwenzeni izixhobo zezolimo ezifana nee-taw, ii-feeder, kunye nee-barn. Olu gqubuthelo lukhusela intsimbi kumhlwa kunye nokugqwala, nto leyo eyenza ifaneleke ukusetyenziswa ngaphandle.

5.Izixhobo zasekhaya: Ii-GI coils zisetyenziswa ekwenzeni izixhobo zasekhaya, ezifana neefriji, ii-oven, oomatshini bokuhlamba impahla, njl. Iingubo ze-galvanized zibonelela ngokugqitywa okuhlala ixesha elide nokunomtsalane okunokumelana neemeko ezinzima.

6. Imizi-mveliso: Iikhoyili zentsimbi ezigayiweyo zisetyenziselwa ukwenza izinto ezahlukeneyo zoshishino ezifana neepayipi, iitanki zokugcina kunye neebhulorho. Olu gquma lubonelela ngokugqwala okugqwesileyo kunye nokukhusela imozulu, nto leyo eyenza ukuba ifaneleke ukusetyenziswa kwimizi-mveliso.

Lilonke, ii-GI coils zizinto eziguquguqukayo nezihlala ixesha elide ezifanelekileyo kwiintlobo ngeentlobo zezicelo kumashishini ahlukeneyo.

| Igama lemveliso | Ikhoyili yentsimbi egalelweyo |

| Ikhoyili yentsimbi egalelweyo | I-ASTM, EN, JIS, GB |

| Ibanga | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye iMfuneko yoMthengi |

| Ubukhulu | I-0.10-2mm ingenziwa ngokwezifiso ngokufanelekileyo imfuneko yakho |

| Ububanzi | 600mm-1500mm, ngokweemfuno zomthengi |

| Ezobugcisa | Ikhoyili eshushu efakwe ngesinyithi |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa i-passivation, Ukufaka i-oyile, ukutywina i-lacquer, i-phosphate, enganyangwanga |

| Umphezulu | i-spangle eqhelekileyo, i-mis spangle, eqaqambileyo |

| Ubunzima bekhoyili | I-2-15metric ton nganye nge-coil |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Isicelo | ukwakhiwa kwesakhiwo, i-gring yentsimbi, izixhobo |

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.