Ishiti yentsimbi egayiweyo ye-ASTM A653M-06a

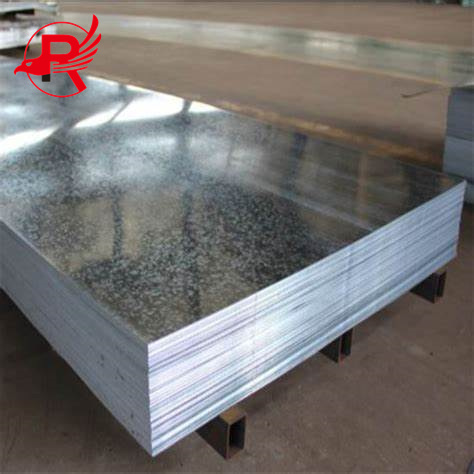

Ishushu-iqengqelekileIshidi lesinyithiyimveliso apho umaleko we-zinc ugqunywe phezu kweshiti yentsimbi eqengqelekayo eshushu. Amaphepha e-galvanized agqunywe ngobushushu adla ngokusebenzisa inkqubo ye-hot-dip galvanizing, ekukuntywilisela i-hot-rolledIpleyiti yentsimbi egalelweyokulwelo lwezinc olunyibilikisiweyo ukwenza umaleko wezinc ofanayo noxineneyo. Olu nyango lunikaIpleyiti yentsimbi eshushu egalelweyoukumelana nokugqwala okugqwesileyo, ukumelana nokuguguleka kunye nokumelana nemozulu. Inkqubo yokuvelisa amaphepha e-galvanized atshisiweyo ashushu ibandakanya amanyathelo amaninzi afana nokulungiswa kwezinto eziluhlaza, ukunyibilikisa i-zinc melt, i-hot-dip galvanizing, kunye nonyango lomphezulu. Iimpawu zamaphepha e-galvanized atshisiweyo ashushu ziquka ukumelana nokugqwala okugqwesileyo, ukumelana nokuguguleka, ukusebenza kakuhle kokucubungula, umphezulu ogudileyo nomhle, kunye nokuqhuba kakuhle kombane. Amaphepha e-galvanized atshisiweyo ashushu asetyenziswa kakhulu ekwakheni, koomatshini, kumbane, kunxibelelwano nakwamanye amasimi. Ahlala esetyenziswa kwizakhiwo zokwakha, kwiinkqubo zokuhambisa amanzi, kwizixhobo zoshishino, koomatshini bezolimo, kwezothutho nakwamanye amasimi. Ukumelana kwayo nokugqwala kwenza ibe yenye yezinto ezifunekayo kumashishini ahlukeneyo.

Amashiti e-galvanized ashushu aneempawu ezahlukeneyo ezenza ukuba asetyenziswe kakhulu kwiindawo ezahlukeneyo. Okokuqala, amashiti e-galvanized ashushu anokumelana nokugqwala okuhle kakhulu. Umaleko we-galvanized unokuthintela ngempumelelo umphezulu wentsimbi ukuba ungagqwali ngumoya, amanzi kunye nezinto zeekhemikhali, ngaloo ndlela wandise ubomi benkonzo yentsimbi. Okwesibini, amashiti e-galvanized ashushu anokumelana nokugqwala okuhle kwaye afanelekile kwiindawo ezifuna ukumelana nokungqubana nokugqwala, njengezakhiwo zokwakha, izixhobo zoomatshini kunye nezinye iindawo. Ukongeza, amashiti e-galvanized ashushu nawo aneempawu ezilungileyo zokucubungula kwaye anokucutshungulwa ngokugoba, ukunyathela, ukuwelda, njl.njl., kwaye afanelekile ukuvelisa iimilo ezahlukeneyo ezintsonkothileyo. Ukongeza, umphezulu wamashiti e-galvanized ashushu uthambile kwaye muhle, kwaye ungasetyenziswa ngokuthe ngqo njengezinto zokuhombisa. Ukongeza, amashiti e-galvanized ashushu nawo anokuqhuba kakuhle kombane kwaye afanelekile kumandla ombane, unxibelelwano kunye nezinye iindawo. Ngokubanzi, ishiti e-galvanized eshushu ibe yenye yezinto ezibalulekileyo kwiindawo zokwakha, oomatshini, umbane, unxibelelwano kunye nezinye iindawo ngenxa yokumelana nokugqwala, ukumelana nokugqwala kunye nokusebenza kakuhle kokucubungula.

Ishiti ye-galvanized egoqwe ngobushushu yimveliso enomaleko we-zinc ogqunywe phezu kweshiti yentsimbi egoqwe ngobushushu. Inokumelana nokugqwala okugqwesileyo kunye neempawu ezahlukeneyo. Ke ngoko, inoluhlu olubanzi lwezicelo kwiindawo ezahlukeneyo.

Okokuqala, kwicandelo lokwakha, amaphepha e-galvanized ajikelezisiweyo ahlala esetyenziswa kwiinkqubo zokuxhasa kunye nokukhupha amanzi kwizakhiwo zokwakha. Ingasetyenziswa kwizakhelo zokwakha, ii-handrails zezitebhisi, ii-railings kunye nezinye izinto, kwaye ingasetyenziswa njengezinto eziphambili zemibhobho yokukhupha amanzi kuba ukumelana kwayo nokugqwala kunokwandisa ubomi bayo benkonzo.

Okwesibini, kwicandelo lemizi-mveliso, amaphepha e-galvanized aqengqelekayo ashushu adla ngokusetyenziswa ukwenza izixhobo ezahlukeneyo kunye nezinto ezinje ngeetanki zokugcina, iipayipi, iifeni, izixhobo zokuhambisa, njl. Ukumelana nokugqwala kwamaphepha e-galvanized kwenza ukuba asetyenziswe ixesha elide kwiindawo zoshishino ezinzima, okuqinisekisa ukusebenza ngokukhuselekileyo kwezixhobo.

Ukongeza, kwicandelo lezolimo, amaphepha e-galvanized agutyungelwe ngobushushu nawo anezicelo ezibalulekileyo. Angasetyenziswa kwiinkqubo zokunkcenkceshela iifama, ukuxhasa izakhiwo zemishini yezolimo, njl. kuba ukumelana nokugqwala kwayo kunokumelana nokukhukuliseka kwezixhobo ziikhemikhali emhlabeni.

Ukongeza, kwicandelo lezothutho, amaphepha e-galvanized ajijekileyo asetyenziswa rhoqo ekwenzeni iinxalenye zeemoto, izinto zeenqanawa, njl.njl., kuba ukumelana kwazo nokugqwala kunokwandisa ubomi benkonzo yezithuthi zothutho.

Ngokubanzi, amaphepha e-galvanized agutyungelwe ngobushushu anezicelo ezibalulekileyo kulwakhiwo, kushishino, kwezolimo, kwezothutho nakwezinye iindawo, kwaye ukumelana kwawo nokugqwala kuwenza abe yenye yezona zinto zifanelekileyo kwizixhobo ezahlukeneyo kunye nezakhiwo.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.