-

Ipayipi yentsimbi ejikelezileyo ye-SAE 1008 1010 1020 eshushu ediphiniweyo egalelweyo

Gumbhobho ohlaziyiweyoyenziwe nge-metal enyibilikisiweyo kunye ne-iron matrix reaction ukuvelisa umaleko we-alloy, ukuze i-matrix kunye ne-coating zibe zimbini.gUkucoca i-alvanizing kukuqala ngokucola ityhubhu yentsimbi. Ukuze kususwe i-iron oxide kumphezulu wetyhubhu yentsimbi, emva kokucola, icocwa etankini nge-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride, emva koko ithunyelwe kwitanki yokucola i-hot dip. I-hot dip galvanizing ineengenelo zokugquma ngokulinganayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo. Iimpendulo ezintsonkothileyo zomzimba nezekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-zinc-iron alloy oqinileyo onokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yetyhubhu yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

Njengoko sinamava angaphezu kweminyaka eli-10 okuthumela intsimbi kumazwe angaphezu kwe-100, sifumene udumo olukhulu kwaye sifumana abathengi abaninzi rhoqo.

Siza kukuxhasa kakuhle kuyo yonke le nkqubo ngolwazi lwethu lobungcali kunye neempahla ezisemgangathweni ophezulu.

Isampulu yesitokhwe isimahla kwaye iyafumaneka! Wamkelekile umbuzo wakho!

-

Umbhobho wentsimbi oshushu oshushu we-15mm otyhidiweyo we-GI Round Steel Pre Galvanized Steel okumgangatho ophezulu

Gumbhobho ohlaziyiweyoyenziwe nge-metal enyibilikisiweyo kunye ne-iron matrix reaction ukuvelisa umaleko we-alloy, ukuze i-matrix kunye ne-coating zibe zimbini.gUkucoca i-alvanizing kukuqala ngokucola ityhubhu yentsimbi. Ukuze kususwe i-iron oxide kumphezulu wetyhubhu yentsimbi, emva kokucola, icocwa etankini nge-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride, emva koko ithunyelwe kwitanki yokucola i-hot dip. I-hot dip galvanizing ineengenelo zokugquma ngokulinganayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo. Iimpendulo ezintsonkothileyo zomzimba nezekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-zinc-iron alloy oqinileyo onokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yetyhubhu yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

-

Umbhobho we-GI Pre Galvanized Steel Pipe Galvanized Tube for Construction

UkuweldaUmbhobho wesinyithiNgokwesiqhelo yenziwa ngentsimbi ekhabhoni ephantsi kwaye isetyenziswa kakhulu kwizicelo ezahlukeneyo ezifana nokwakha, iziseko zophuhliso, iiprojekthi zoshishino, kunye neendawo zokuhlala. Inkqubo yokufakelwa kwe-galvanization inika umbhobho wentsimbi ukuqina okongeziweyo kunye nexesha elide, okwenza ukuba ufaneleke kwiimeko zangaphandle nezibonakalayo.

Inzuzo ephambili yeumbhobho wentsimbi owenziwe nge-galvanized kwangaphambiliyimeko yayo yokungagqwali. Ingubo ye-zinc isebenza njengomqobo othintela umswakama kunye nezinye izinto ezigqwalisiweyo ukuba zingadibani nentsimbi engaphantsi. Oku kwenza umbhobho wentsimbi osele ufakwe i-galvanized ungachaphazeleki kakhulu kukugqwala nokugqwala, nto leyo eyandisa ubomi bayo kwaye inciphise iindleko zokulungisa.

Ngaphezu koko,I-Hot Dip egalelweyoyaziwa ngamandla ayo aphezulu kunye nokuqina kwayo. Iyakwazi ukumelana nemithwalo enzima kwaye inika ulungelelwaniso oluhle kakhulu lwesakhiwo, nto leyo eyenza ukuba ibe lukhetho oluthembekileyo kwiizicelo ezifuna umbhobho oqinileyo noqinileyo.

-

Iityhubhu kunye neePipe zeSinki eziGqitywe ngeZinc, iSicaffolding Tube, iSipipe seSinyithi esishushu esifakwe kwiGalvanized

IntsimbiisikafolidiIsibiyeli sisakhiwo sexeshana esibonelela ngeqonga elizinzileyo labasebenzi lokwenza umsebenzi wokwakha, wokulungisa okanye wokulungisa kwiindawo eziphakamileyo. Siqulathe imibhobho yentsimbi kunye nezixhobo ezidityanisiweyo ukwenza isakhelo esizinzileyo. Izibonelelo ze-scaffolding zentsimbi zinokwahluka ngobukhulu kunye nolwakhiwo, kuxhomekeke kuhlobo lomsebenzi ekufuneka wenziwe kunye nokuphakama okufunekayo.

-

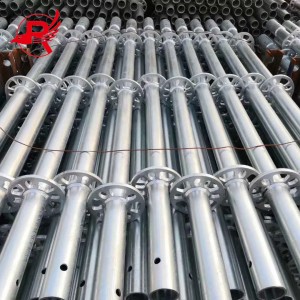

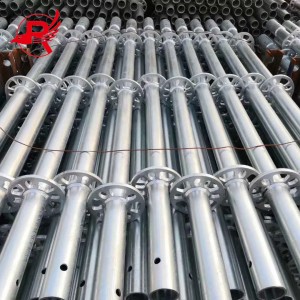

I-Scaffold epheleleyo ye-Metal Heavy Duty I-Hot Dip egayiweyo yonke i-Round Layher Ringlock System Scaffolding iyathengiswa

IntsimbiisikafolidiIsibiyeli sisakhiwo sexeshana esibonelela ngeqonga elizinzileyo labasebenzi lokwenza umsebenzi wokwakha, wokulungisa okanye wokulungisa kwiindawo eziphakamileyo. Siqulathe imibhobho yentsimbi kunye nezixhobo ezidityanisiweyo ukwenza isakhelo esizinzileyo. Izibonelelo ze-scaffolding zentsimbi zinokwahluka ngobukhulu kunye nolwakhiwo, kuxhomekeke kuhlobo lomsebenzi ekufuneka wenziwe kunye nokuphakama okufunekayo.

-

I-Scaffold yeNsimbi yoLwakhiwo oluSetyenzisiweyo olusemgangathweni ophezulu iyathengiswa

IntsimbiisikafolidiIsibiyeli sisakhiwo sexeshana esibonelela ngeqonga elizinzileyo labasebenzi lokwenza umsebenzi wokwakha, wokulungisa okanye wokulungisa kwiindawo eziphakamileyo. Siqulathe imibhobho yentsimbi kunye nezixhobo ezidityanisiweyo ukwenza isakhelo esizinzileyo. Izibonelelo ze-scaffolding zentsimbi zinokwahluka ngobukhulu kunye nolwakhiwo, kuxhomekeke kuhlobo lomsebenzi ekufuneka wenziwe kunye nokuphakama okufunekayo.

-

Ityhubhu ye-scaffolding eshushu etyibiliziweyo ngentsimbi eqinisiweyo

Gumbhobho ohlaziyiweyoyenziwe nge-metal enyibilikisiweyo kunye ne-iron matrix reaction ukuvelisa umaleko we-alloy, ukuze i-matrix kunye ne-coating zibe zimbini.gUkucoca i-alvanizing kukuqala ngokucola ityhubhu yentsimbi. Ukuze kususwe i-iron oxide kumphezulu wetyhubhu yentsimbi, emva kokucola, icocwa etankini nge-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride, emva koko ithunyelwe kwitanki yokucola i-hot dip. I-hot dip galvanizing ineengenelo zokugquma ngokulinganayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo. Iimpendulo ezintsonkothileyo zomzimba nezekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-zinc-iron alloy oqinileyo onokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yetyhubhu yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

Njengoko sinamava angaphezu kweminyaka eli-10 okuthumela intsimbi kumazwe angaphezu kwe-100, sifumene udumo olukhulu kwaye sifumana abathengi abaninzi rhoqo.

Siza kukuxhasa kakuhle kuyo yonke le nkqubo ngolwazi lwethu lobungcali kunye neempahla ezisemgangathweni ophezulu.

Isampulu yesitokhwe isimahla kwaye iyafumaneka! Wamkelekile umbuzo wakho!

-

I-HDG Tube China Factory Ixabiso Elithe Ngqo Iipayipi Zentsimbi Ezijikelezileyo Ezigayiweyo Ezigayiweyo

Umbhobho wentsimbi ejikelezileyo egalelwe ngesinyithiluhlobo lombhobho wentsimbi ongqukuva onomphezulu ophathwa nge-hot-dip galvanizing okanye i-cold-dip galvanizing, onika ukumelana nokugqwala okuhle kakhulu kunye nokuqina. Isetyenziswa kakhulu ekwakheni, kwimveliso yoomatshini, kwizibonelelo zezolimo, ekuthuthweni kwemibhobho, kwiindlela zokukhusela, nakwizakhiwo zoshishino.

-

I-EN10255 8 intshi S235 Intsimbi Eshushu Eqengqelekayo Ethambileyo Yekhabhoni Enezinki Egqunywe Yintsimbi Egayiweyo Neetyhubhu

Gumbhobho ohlaziyiweyoyenziwe nge-metal enyibilikisiweyo kunye ne-iron matrix reaction ukuvelisa umaleko we-alloy, ukuze i-matrix kunye ne-coating zibe zimbini.gUkucoca i-alvanizing kukuqala ngokucola ityhubhu yentsimbi. Ukuze kususwe i-iron oxide kumphezulu wetyhubhu yentsimbi, emva kokucola, icocwa etankini nge-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride, emva koko ithunyelwe kwitanki yokucola i-hot dip. I-hot dip galvanizing ineengenelo zokugquma ngokulinganayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo. Iimpendulo ezintsonkothileyo zomzimba nezekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-zinc-iron alloy oqinileyo onokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yetyhubhu yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

-

I-Astm Hot Dip Ms GI Galvanized Welded Carbon Steel Round Pipe

I-hot-dip galvanization luhlobo lwe-galvanization. Yinkqubo yokugquma intsimbi kunye nentsimbi nge-zinc, edibanisa nomphezulu wesinyithi esisisiseko xa untywilisela isinyithi kwibhafu ye-zinc enyibilikisiweyo kubushushu obumalunga ne-450 °C (842 °F).

-

Umbhobho ojikelezileyo wentsimbi egqunywe yi-zinc eshushu edityaniswe ne-1/2 intshi

Gumbhobho ohlaziyiweyoyenziwe nge-metal enyibilikisiweyo kunye ne-iron matrix reaction ukuvelisa umaleko we-alloy, ukuze i-matrix kunye ne-coating zibe zimbini.gUkucoca i-alvanizing kukuqala ngokucola ityhubhu yentsimbi. Ukuze kususwe i-iron oxide kumphezulu wetyhubhu yentsimbi, emva kokucola, icocwa etankini nge-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo samanzi esixutyiweyo se-ammonium chloride kunye ne-zinc chloride, emva koko ithunyelwe kwitanki yokucola i-hot dip. I-hot dip galvanizing ineengenelo zokugquma ngokulinganayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo. Iimpendulo ezintsonkothileyo zomzimba nezekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu enyibilikisiweyo ukuze zenze umaleko we-zinc-iron alloy oqinileyo onokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye ne-matrix yetyhubhu yentsimbi. Ke ngoko, ukumelana kwayo nokugqwala kunamandla.

-

Umbhobho wentsimbi ejikelezileyo eshushu ene-DIP 60.3 * 2.5mm Welded Galvanized for Construction

I-hot-dip galvanizing yindlela yokugaya kwaye yeyona ndlela ixhaphakileyo yokufaka i-zinc coating. Kule nkqubo, isinyithi sintywiliselwa kwibhafu ye-zinc enyibilikisiweyo malunga ne-450 °C (842 °F). I-zinc isabela kumphezulu wesinyithi kwaye yenze umaleko we-alloy omelana nokugqwala okhusela isinyithi.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur