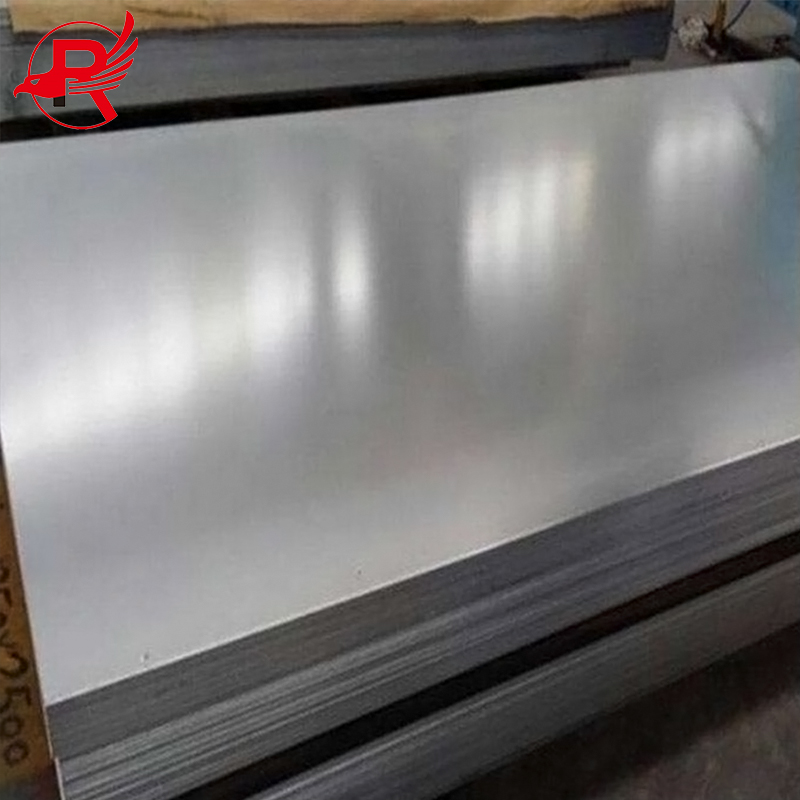

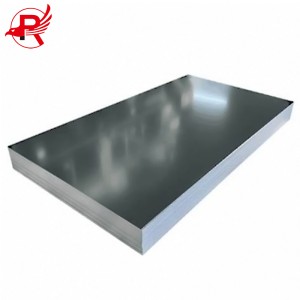

Iphepha lesinyithi eligalelweyo le-SGCE 1mm 3mm 5mm 6mm Ipleyiti yesinyithi esemgangathweni olungileyo

Iishiti zentsimbi ze-GI ziishiti ezenziwe ngentsimbi egayiweyo (GI). I-Galvanization yinkqubo yokugquma isinyithi okanye intsimbi ngomaleko we-zinc ukuthintela ukugqwala. Iishiti ze-GI zihlala zisetyenziselwa uphahla, uthango, kunye nokusetyenziswa ngaphandle ngenxa yokuqina kwazo kunye nokumelana nokugqwala kunye nokugqwala.

Ubukhulu bamaphepha e-GI bulinganiswa nge-gauge, apho i-gauge esezantsi ibonisa iphepha elinobukhulu. Ezona gauge ziqhelekileyo zamaphepha e-GI ziqala kwi-18 ukuya kwi-24. Ububanzi bamaphepha e-GI buhlala buqala kwi-600mm ukuya kwi-1500mm.

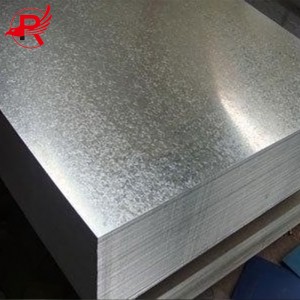

Ipleyiti yentsimbi egalelweyoZifumaneka ngeentlobo ezimbini zokugquma: i-regular spangle kunye ne-zero spangle. Amaphepha e-GI e-spangle aqhelekileyo anepateni ebonakalayo efana ne-spangle kumphezulu, edalwa ngexesha lenkqubo yokugaya i-galvanizing. Amaphepha e-GI e-zero spangle anendawo egudileyo kwaye akanayo ipateni ebonakalayo ye-spangle.

Iphepha leNtsimbi elisegadiniZingahlulwa-hlulwa ngokusekelwe kwindlela ezisetyenziswa ngayo. Ezinye zeentlobo eziqhelekileyo zamaphepha e-GI ziquka:

1. Ii-GI Sheets zeCorrugated - ezisetyenziselwa ukufulela, iiphaneli zodonga, kunye nocingo.

2. Iiphepha zeGI ezingenanto - ezisetyenziselwa ukusetyenziswa ngaphakathi njengeepayipi zokuhambisa amanzi, iiphaneli zombane, kunye nefenitshala.

3. IiGalvalume GI Sheets - indibaniselwano yee-aluminium kunye nee-zinc-coated GI sheets ezibonelela ngokumelana nokugqwala okuphezulu.

4. Iiphepha zeGI ezipeyintwe kwangaphambili - Iiphepha zeGI ezigqunywe ngomaleko wepeyinti, ezisetyenziswa kakhulu ekufakeni uphahla kunye nokufakwa kwengubo.

Amaphepha e-GI afumaneka kwiindidi ezahlukeneyo ngokusekelwe kumandla awo kunye nokuqina kwawo. Amanqaku asetyenziswa kakhulu kwiindidi ze-GI yi-SGCC, i-SGHC, kunye ne-DX51D.

1. Ukumelana nokugqwala, ukupeyinta, ukwakheka kakuhle kunye nokudityaniswa kwamabala.

2. Inoluhlu olubanzi lokusetyenziswa, ikakhulu isetyenziselwa izixhobo zasekhaya ezincinci ezifuna inkangeleko entle, kodwa ibiza kakhulu kune-SECC, ngoko ke abavelisi abaninzi batshintshela kwi-SECC ukuze bonge iindleko.

3. Yahlulwe yizinc: ubungakanani be-span kunye nobukhulu bomaleko wezinc bunokubonisa umgangatho we-galvanizing, okukhona incinci kwaye ityebile kokukhona ingcono. Abavelisi banokongeza unyango oluchasene nokuprintwa kweminwe. Ukongeza, inokwahlulwa ngokugqunywa kwayo, njenge-Z12, oko kuthetha ukuba isixa sisonke sokugqunywa kumacala omabini yi-120g/mm.

Iiphepha zeGI zineendlela ezahlukeneyo zokusetyenziswa kumashishini namacandelo ahlukeneyo. Ezinye zeendlela eziqhelekileyo zokusetyenziswa kweephepha zeGI zezi:

1. Uphahla kunye noGutyulo:Ipleyiti yentsimbi eshushu egalelweyoziyindlela ethandwayo yokusetyenziswa kophahla kunye nokufakwa kwe-cladding ngenxa yokuqina kwazo, ukumelana nokugqwala, kunye namandla. Zisetyenziswa kakhulu kwizakhiwo zokuhlala, zorhwebo, kunye nezakhiwo zemizi-mveliso.

2. Ukubiyela: Ii-GI sheets zisetyenziselwa ukwenza ucingo kunye nokwahlulahlula ngenxa yokuba zinamandla kwaye azikwazi ukumelana nomhlwa. Zikwasetyenziswa njengeendonga zomda ngeenjongo zokhuseleko.

3. Iimoto: Iishiti zeGI zisetyenziselwa ukwenza iindawo zemoto ezifana neephaneli zomzimba, uphahla, kunye netshasi ngenxa yokuqina nokuqina kwazo.

4. I-HVAC: Amaphepha e-GI asetyenziswa kwishishini lokufudumeza, ukuphefumla, kunye nokuphola komoya (i-HVAC) kwiipayipi zomoya, iiyunithi zokuphola, kunye neenkqubo zokuphola.

5. Ukwenziwa: Amaphepha e-GI asetyenziswa kwishishini lokwenziwa kwempahla ukuvelisa iimveliso ezahlukeneyo ezifana neekhabhathi, iishelufu, ifenitshala, kunye nezinye iimveliso zesinyithi.

6. Ezombane: Iishiti ze-GI zisetyenziselwa ukwenza iiphaneli zombane ezivalekileyo ngenxa yokuqina kwazo, amandla azo, kunye nokumelana nokugqwala.

7. Ezolimo: Amaphepha eGI asetyenziswa kwezolimo ekwakheni iishedi zeenkukhu, iigreenhouse, kunye neendawo zokugcina.

Ngokubanzi, amaphepha e-GI anika isisombululo esithembekileyo nesingabizi kakhulu kwizicelo ezininzi kwaye asetyenziswa kakhulu kumashishini amaninzi nakumacandelo.

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lentsimbi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

| Itheyibhile yokuthelekisa ubungqingqwa beGauge | ||||

| Igeyiji | Ubuthambileyo | I-aluminiyam | I-Galvanised | Ingenasici |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Angakanani amaxabiso akho?

Amaxabiso ethu anokutshintsha ngokuxhomekeke kubonelelo kunye nezinye izinto ezikwimarike. Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva kokunxibelelana nenkampani yakho.

nathi ukuze ufumane ulwazi oluthe kratya.

2. Ngaba unayo iodolo encinci?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe zibe nomlinganiselo omncinci we-odolo oqhubekayo. Ukuba ujonge ukuthengisa kwakhona kodwa ngobuninzi obuncinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu.

3. Ngaba ungasinika amaxwebhu afanelekileyo?

Ewe, singabonelela ngobuninzi bamaxwebhu kuquka neeSatifikethi zoHlalutyo/zoKuhambelana neMithetho; i-Inshorensi; iMvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kufuneka khona.

4. Lithini ixesha eliqhelekileyo lokunika ingqwalasela?

Kwiisampuli, ixesha lokunika i-lead limalunga neentsuku ezisi-7. Kwimveliso enkulu, ixesha lokunika i-lead limalunga neentsuku ezi-5-20 emva kokufumana intlawulo yedipozithi. Amaxesha okunika i-lead aqala ukusebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho. Ukuba amaxesha ethu okufumana imveliso awasebenzi nomhla wokugqibela, nceda ujonge iimfuno zakho ngokuthengisa kwakho. Kuzo zonke iimeko siya kuzama ukuhlangabezana neemfuno zakho. Kwiimeko ezininzi siyakwazi ukwenza njalo.

5. Zeziphi iindlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T/T, i-70% iya kuba ngaphambi kokuthunyelwa kwesiseko kwi-FOB; i-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL basic kwi-CIF.