Umbhobho woMgca oNgenamthungo we-API 5L Gr. B Carbon

| Amabanga | I-API 5L Ibanga B, X42, X52, X56, X60, X65, X70, X80 |

| Inqanaba leNkcazelo | I-PSL1, i-PSL2 |

| Uluhlu lobubanzi bangaphandle | 1/2” ukuya kwi-2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches ukuya kuthi ga kwi-40 inches. |

| Ishedyuli yoButyebi | I-SCH 10. I-SCH 20, I-SCH 40, I-SCH STD, I-SCH 80, I-SCH XS, ukuya kwi-SCH 160 |

| Iintlobo zoMveliso | Ayinamthungo (Iqengqeleke ngobushushu kwaye Iqengqeleke ngobandayo), I-Welded ERW (Inyibilikisiwe ngombane), I-SAW (Igqunywe nge-Arc engaphantsi komhlaba) kwi-LSAW, DSAW, SSAW, HSAW |

| Uhlobo Lokuphela | Iziphelo ezigobileyo, Iziphelo ezicacileyo |

| Uluhlu lobude | I-SRL (Ubude obungacwangciswanga obunye), i-DRL (Ubude obuphindwe kabini obungacwangciswanga), i-20 FT (iimitha ezi-6), i-40 FT (iimitha ezili-12) okanye, eyenziwe ngokwezifiso |

| Iikhephu zoKhuselo | iplastiki okanye isinyithi |

| Unyango Lomphezulu | Ipeyinti yendalo, evarnished, emnyama, i-FBE, i-3PE (3LPE), i-3PP, i-CWC (Inobunzima bekhonkrithi obugqunywe) i-CRA Clad okanye i-Lined |

Umbhobho we-API 5L ubhekisa kumbhobho wentsimbi yekhabhoni osetyenziswa kwiinkqubo zokuhambisa ioyile negesi. Ukwasetyenziselwa ukuthutha ezinye izinto ezinje ngomphunga, amanzi, nodaka.

Inkcazo ye-API 5L igubungela zombini iintlobo zokwenza izinto ezidityanisiweyo nezingenamthungo.

Iintlobo ezidityanisiweyo: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Iindidi eziqhelekileyo zepayipi ye-API 5L ewelded zezi zilandelayo:

I-ERW: Ukuwelda kokumelana nombane, okuqhele ukusetyenziswa kwiipayiphu ezingaphantsi kwee-intshi ezingama-24.

I-DSAW/SAW: Ukuwelda kwe-arc engaphantsi kwamanzi emacaleni amabini/ukuwelda kwe-arc engaphantsi komhlaba, indlela eyahlukileyo yokuwelda endaweni ye-ERW esetyenziselwa imibhobho emikhulu.

I-LSAW: Ukuwelda kwe-arc engaphantsi komhlaba okude, okusetyenziselwa ububanzi bepayipi ukuya kuthi ga kwi-intshi ezingama-48. Kwaziwa nangokuba yinkqubo yokwenziwa kwe-JCOE.

I-SSAW/HSAW: Ukuwelda kwe-arc engaphantsi komhlaba/ukuwelda kwe-arc engaphantsi komhlaba, okusetyenziselwa ububanzi bepayipi ukuya kuthi ga kwi-100 intshi.

Iintlobo zePipe engenamthungo: Ipipe engenamthungo eshushu egoqwe kakuhle I-Cold rolled

Umbhobho wentsimbi engenamthungo usetyenziswa kakhulu kwiipayipi ezincinci ezinobubanzi obuncinci (ngesiqhelo zingaphantsi kwee-intshi ezingama-24).

(Ipayipi yentsimbi engenamthungo ikhethwa ngaphezu kwepayipi edibeneyo enobubanzi obungaphantsi kwe-150 mm (ii-in ezi-6)).

Senza nombhobho omkhulu ongenamthungo. Ngokusebenzisa inkqubo eqengqelekayo eshushu, umbhobho ongenamthungo onobubanzi obuphezulu obuyi-20 intshi (508 mm) unokwenziwa. Ukuba ufuna umbhobho ongenamthungo onobubanzi obungaphezulu kwe-20", singawuvelisa umbhobho ongenamthungo ngenkqubo ekhuliswe ngobushushu enobubanzi obufikelela kwi-40" (1016 mm).

I-API 5L ibandakanya amanqanaba afana neBakala B, X42, X46, X52, X56, X60, X65, X70 kunye ne-X80.

I-API 5L Steel Pipe ifumaneka kwiindidi ezahlukeneyo zentsimbi kuquka iBanga B, i-X42, i-X46, i-X52, i-X56, i-X60, i-X65, i-X70 kunye ne-X80. Okukhona inqanaba lentsimbi liphezulu, kokukhona ulawulo olulinganayo lwekhabhoni luqina kwaye kokukhona iimpawu zamandla oomatshini ziphezulu.

Ngaphezu koko, ukwakheka kweekhemikhali kwemibhobho ye-API 5L edibeneyo nengenamthungo enomgangatho ofanayo wentsimbi kunomahluko, apho imibhobho edibeneyo ineemfuno eziphezulu kunye nomxholo omncinci wekhabhoni nesalfure.

Ulwakhiwo lweeKhemikhali kwi-PSL 1 pipe ene-t ≤ 0.984” | |||||||

| Ibanga lentsimbi | Iqhezu lobunzima, i-% isekelwe kubushushu kunye nohlalutyo lwemveliso a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| ubuninzi b | ubuninzi b | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | |

| Umbhobho ongenamthungo | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Umbhobho odibeneyo | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; kunye ne-Mo ≤ 0.15%, | |||||||

| b. Kwixabiso ngalinye lokunciphisa i-0.01% ngaphantsi koxinzelelo oluphezulu oluchaziweyo lwekhabhoni, ukunyuka kwe-0.05% ngaphezu koxinzelelo oluphezulu oluchaziweyo lwe-Mn kuvumelekile, ukuya kuthi ga kwi-1.65% kwiigreyidi ≥ L245 okanye B, kodwa ≤ L360 okanye X52; ukuya kuthi ga kwi-1.75% kwiigreyidi > L360 okanye X52, kodwa < L485 okanye X70; kwaye ukuya kuthi ga kwi-2.00% kwiigreyidi L485 okanye X70. | |||||||

| c. Ngaphandle kokuba kuvunyelwene ngenye indlela QAPHELA + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Ngaphandle kokuba kuvunyelwene ngenye indlela., | |||||||

| f. Ngaphandle kokuba kuvunyelwene ngenye indlela, QAPHELA + V = Ti ≤ 0.15%, | |||||||

| g. Akukho kongezwa ngabom kwe-B okuvumelekileyo kwaye intsalela ye-B ≤ 0.001% | |||||||

| Ulwakhiwo lweeKhemikhali kwipayipi yePSL 2 ene-t ≤ 0.984” | |||||||||||||||||||||

| Ibanga lentsimbi | Inxalenye yobunzima, ipesenti isekelwe kubushushu kunye nohlalutyo lwemveliso | I-Carbon Equiv a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Okunye | I-CE IIW | I-CE Pcm | |||||||||||

| ubuninzi b | ubuninzi | ubuninzi b | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ||||||||||||

| Umbhobho ongenamthungo kunye nowelding | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Njengoko kuvunyelwene | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | mna,j | Njengoko kuvunyelwene | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Njengoko kuvunyelwene | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Njengoko kuvunyelwene | |||||||||||

| Umbhobho odibeneyo | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| I-X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | mna,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | mna,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | mna,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, imida ye-CE iya kuba njengoko kuvunyelwene ngako. Imida ye-CEIIW esetyenziswayo fi C > 0.12% kunye nemida ye-CEPcm iyasebenza ukuba C ≤ 0.12%, | |||||||||||||||||||||

| b. Kwisaphulelo ngasinye se-0.01% ngaphantsi komlinganiselo ochaziweyo we-C, ukunyuka kwe-0.05% ngaphezu komlinganiselo ochaziweyo we-Mn kuvumelekile, ukuya kuthi ga kwi-1.65% kwiibakala ≥ L245 okanye B, kodwa ≤ L360 okanye X52; ukuya kuthi ga kwi-1.75% kwiibakala > L360 okanye X52, kodwa < L485 okanye X70; ukuya kuthi ga kwi-2.00% kwiibakala ≥ L485 okanye X70, kodwa ≤ L555 okanye X80; kwaye ukuya kuthi ga kwi-2.20% kwiibakala > L555 okanye X80. | |||||||||||||||||||||

| c. Ngaphandle kokuba kuvunyelwene ngenye indlela Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% kunye ne-Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Ngaphandle kokuba kuvunyelwene ngenye indlela, | |||||||||||||||||||||

| g. Ngaphandle kokuba kuvunyelwene ngenye indlela, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% kunye ne-MO ≤ 0.50%, | |||||||||||||||||||||

| i. Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% kunye ne-MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% kunye ne-MO ≤ 0.80%, | |||||||||||||||||||||

| l. Kuzo zonke ii-PSL 2 pipe grades ngaphandle kwezo grades zine-footnotes j eziphawuliweyo, oku kulandelayo kuyasebenza. Ngaphandle kokuba kuvunyelwene ngenye indlela akukho kongezwa ngabom kwe-B okuvunyelweyo kwaye intsalela ye-B ≤ 0.001%. | |||||||||||||||||||||

| I-PSL | Imeko yokuhanjiswa | Inqanaba lombhobho |

| I-PSL1 | Njengoko iqengqelekile, iqhelekile, iqhelekile yenziwe | A |

| Njengoko iqengqiwe, iqengqiwe ngendlela eqhelekileyo, iqengqiwe ngendlela ye-thermomechanical, yenziwe ngendlela ye-thermomechanical, ihlengahlengisiwe ngendlela eqhelekileyo, ihlengahlengisiwe kwaye iqiniswe okanye ukuba kuvunyelwene nge-Q&T SMLS kuphela | B | |

| Njengoko iqengqiwe, iqengqiwe ngokwesiqhelo, iqengqiwe ngokwe-thermomechanical, yenziwe ngokwe-thermomechanical, iqhelekile, yenziwe ngokwesiqhelo kwaye ithambile | X42, X46, X52, X56, X60, X65, X70 | |

| I-PSL 2 | Njengoko iqengqelwe | I-BR, X42R |

| Ukulungisa okuqengqelekayo, okwenziwayo, okwenziwayo okanye okwenziwayo kunye nokulungiswa | I-BN, X42N, X46N, X52N, X56N, X60N | |

| Icinyiwe kwaye ithambile | I-BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| I-Thermomechanical rolled okanye i-thermomechanical yenziwe | I-BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| I-Thermomechanical rolled | X90M, X100M, X120M | |

| Okwaneleyo (R, N, Q okanye M) kwiigreyidi zePSL2, zezodidi lwentsimbi |

I-PSL sisifinyezo seNqanaba leNkcazelo yeMveliso kwaye siquka i-PSL1 kunye ne-PSL2. Ifana nenqanaba lomgangatho.

I-PSL1 kunye ne-PSL2 zahlukile kungekuphela nje kuvavanyo, kodwa nakwindlela ekwakhiwe ngayo iikhemikhali kunye neempawu zoomatshini.

I-PSL2 ingqongqo ngakumbi kune-PSL1 malunga nokwakheka kweekhemikhali, iimpawu zokuxinana, uvavanyo lokuchaphazeleka, uvavanyo olungatshabalalisiyo, njl.njl.

Uvavanyo lweMpembelelo

Uvavanyo lwempembelelo - Akufuneki kwiPSL1, kodwa luyimfuneko kwiPSL2 (ngaphandle kweX80).

Uvavanyo olungonakalisiyo

I-PSL1 ayifuni uvavanyo olungatshabalalisiyo kodwa i-PSL2 iyafuna.

(Uvavanyo olungonakalisiyo: Uvavanyo olungonakalisiyo novavanyo olusemgangathweni we-API 5L lusebenzisa iindlela ze-radiographic, i-ultrasound, okanye ezinye iindlela (ngaphandle kokutshabalalisa izinto) ukufumanisa iziphene kunye nokungafezeki kwimibhobho.)

Ukupakisha kukhongokubanzi uhamba ze, ukubopha ucingo lwentsimbi, kakhuluomelele.

Ukuba uneemfuno ezizodwa, ungasebenzisaukupakishwa okungenamhlwa, kwaye intle ngakumbi.

Amanyathelo okhuseleko xa kupakishwa kwaye kuthuthwa imibhobho yentsimbi yekhabhoni

1.Umbhobho wentsimbi we-API 5Lkufuneka ikhuselwe kumonakalo obangelwa kukungqubana, ukukhupha kunye nokusikeka ngexesha lokuthuthwa, ukugcinwa kunye nokusetyenziswa.

2. Xa usebenzisa imibhobho yentsimbi yekhabhoni, kufuneka ulandele iinkqubo zokusebenza zokhuseleko ezifanelekileyo kwaye uqaphele ukuthintela ukuqhuma, imililo, ityhefu kunye nezinye iingozi.

3. Ngexesha lokusetyenziswa,Ipayipi ye-API 5L yentsimbi yekhabhonikufuneka kuthintelwe ukudibana namaqondo obushushu aphezulu, izinto ezibangela ukubola, njl. Ukuba zisetyenziswa kwezi ndawo, kufuneka kukhethwe imibhobho yentsimbi yekhabhoni eyenziwe ngezinto ezikhethekileyo ezifana nokumelana namaqondo obushushu aphezulu kunye nokumelana nokubola.

4. Xa kukhethwa imibhobho yentsimbi yekhabhoni, imibhobho yentsimbi yekhabhoni enezixhobo ezifanelekileyo kunye neenkcukacha kufuneka ikhethwe ngokusekelwe kwizinto ezibanzi ezifana nendawo yokusetyenziswa, iimpawu eziphakathi, uxinzelelo, ubushushu kunye nezinye izinto.

5. Ngaphambi kokuba kusetyenziswe imibhobho yentsimbi yekhabhoni, kufuneka kwenziwe uhlolo novavanyo olufunekayo ukuqinisekisa ukuba umgangatho wayo uyahlangabezana neemfuno.

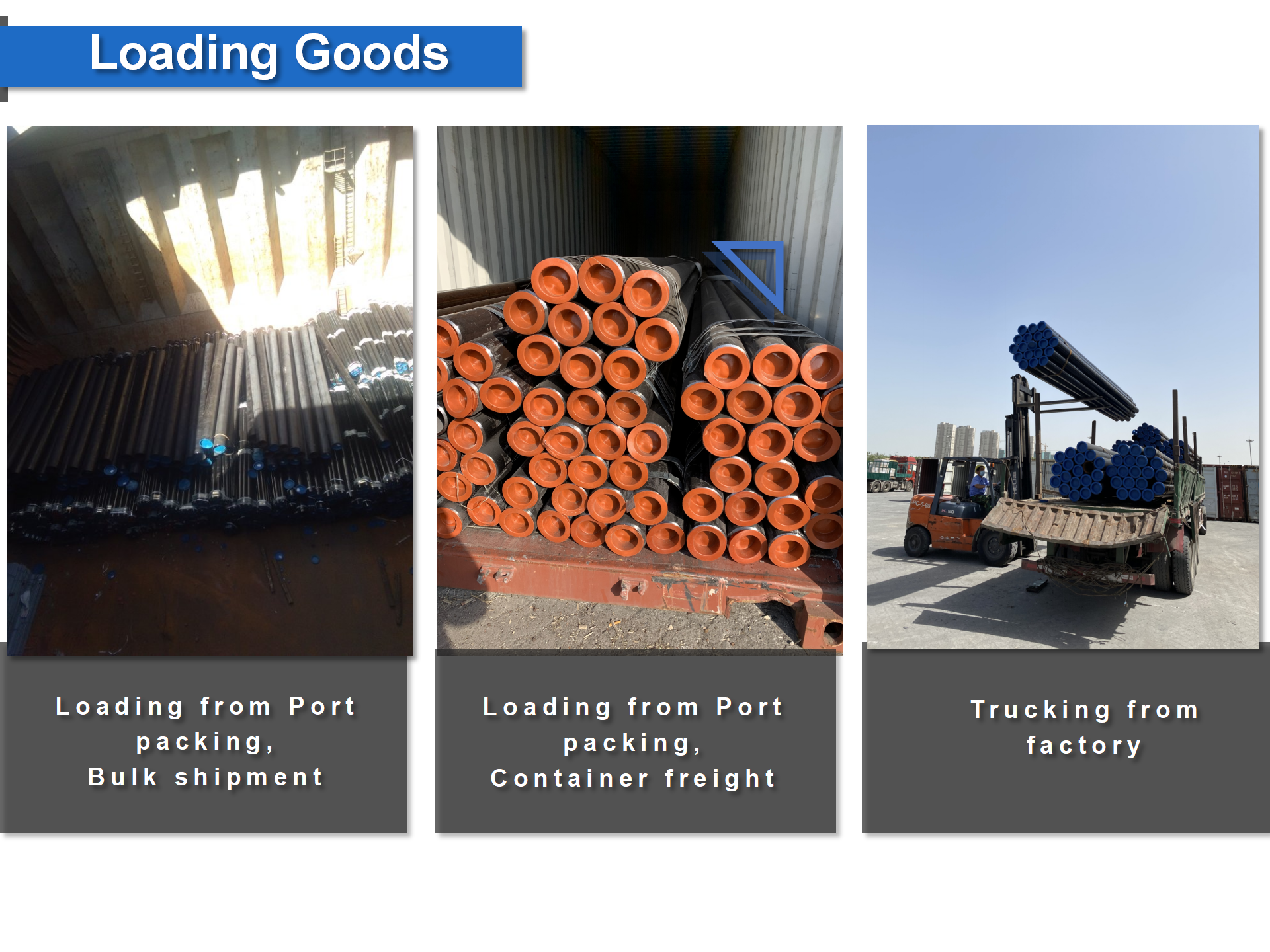

Uthutho:Ukuhanjiswa ngokukhawuleza (Umzekelo wokuhanjiswa), Umoya, uLoliwe, uMhlaba, ukuthunyelwa ngolwandle (I-FCL okanye i-LCL okanye iBulk)

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabavelisi beetyhubhu zentsimbi ezijikelezayo ezikwilali yaseDaqiuzhuang, kwisixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka eli-13 kwaye samkela isiqinisekiso sorhwebo.