Umgangatho oPhezulu weGi yentsimbi yentsimbi yombhobho yentsimbi yombhobho iyathengiswa

Umbhobho wediphu oshushuyenziwe ngentsimbi etyhidiweyo kunye nentsimbi matrix reaction ukuvelisa umaleko ingxubevange, ukuze matrix kunye ukutyabeka indibaniselwano ezimbini.Ukugalela idiphu eshushu kukuqala ukuchola ityhubhu yentsimbi.Ukuze ukususa i-iron oxide phezu komphezulu wetyhubhu yentsimbi, emva kokukhetha, icoca kwitanki ye-ammonium chloride okanye isisombululo se-zinc chloride okanye isisombululo esixutywe ngamanzi se-ammonium chloride kunye ne-zinc chloride, kwaye emva koko ithunyelwe kwidiphu eshushu. itanki.I-Hot dip galvanizing ineenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende.Iimpendulo ezintsonkothileyo zomzimba kunye neekhemikhali zenzeka phakathi kwesiseko setyhubhu yentsimbi kunye nebhafu etyhidiweyo ukwenza i-compact zinc-iron alloy layer with corrosion resistance.Uluhlu lwe-alloy luhlanganiswe ne-zinc ecocekileyo kunye ne-tube matrix yensimbi.Ngoko ke, ukuxhathisa kwayo kunamandla.

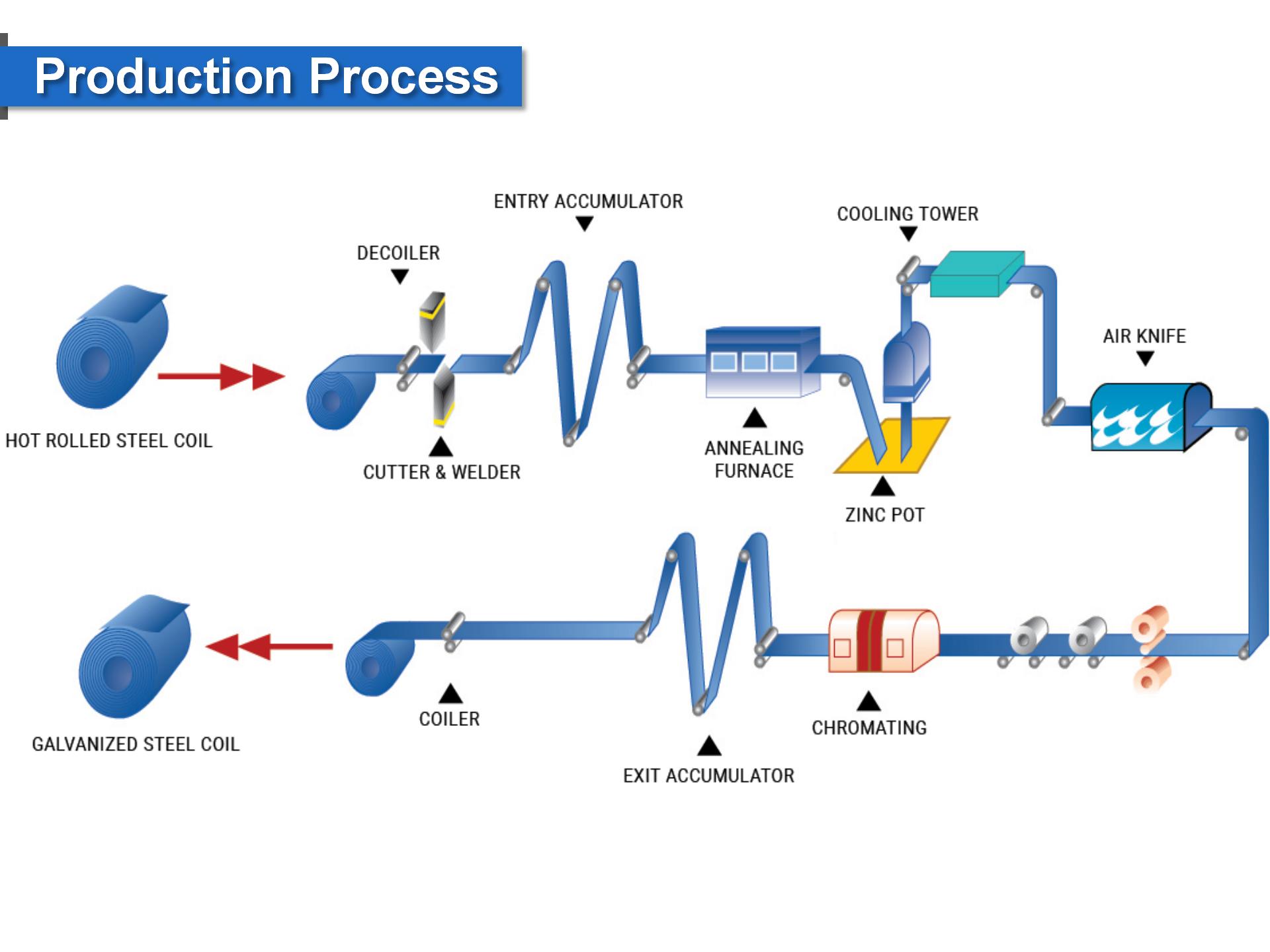

Iinkqubo yemvelisoumbhobho wentsimbi galvanized ibandakanya la manyathelo alandelayo:

1. Iikhoyili zentsimbi: Iibhobho zensimbi ezenziwe ngesinyithi zenziwe ngeentsimbi eziphezulu zensimbi ezishushu ezifakwe kubukhulu obufunwayo kunye nokuma.

2. Ukucoca: I-coil yensimbi ihlanjululwa ukuze isuse nayiphi na i-rust, ioli okanye ezinye izinto ezingcolileyo ezinokuchaphazela umgangatho wemveliso yokugqibela.

3. Flux: Ikhoyili idluliswa kwibhafu ye-flux enesisombululo se-zinc ammonium chloride.Esi sisombululo sinceda ukususa nakuphi na ukungcola okuseleyo kwaye silungiselele indawo yentsimbi kwisinyathelo esilandelayo.

4. Ukugalela: Dipha ikhoyili kwi-zinc etyhidiweyo ukuvala ngokupheleleyo umphezulu wentsimbi.Le nkqubo ngamanye amaxesha ibizwa ngokuba yi-hot dip galvanizing.

5. Ukupholisa: Pholisa ikhoyili emva kokugalela ukuqinisa i-zinc layer.

6. Ukusika kunye nokwenza: Ikhoyili ke isikwa ukuya kubude obufunwayo kwaye yenziwe ibe yityhubhu.

7. Uvavanyo: Iityhubhu zivavanywa ukuqinisekisa ukuba ziyahlangabezana nemigangatho efunekayo yamandla, ukuqina kunye nokumelana nokubola.

8. Ukugcinwa kunye nokuhanjiswa: Iityhubhu zigcinwa kwaye zisasazwe kubathengi.

Inkqubo yokuvelisa umbhobho wensimbi yensimbi ilula kwaye ivelisa umgangatho ophezulu, imveliso ehlala ixesha elide ifanelekile kwizicelo ezininzi.

Iimbonakalo

1. Ukumelana nokukhula: Ukugalela igalvanizing yindlela yoqoqosho nesebenzayo yokuthintela umhlwa edla ngokusetyenziswa.Malunga nesiqingatha semveliso ye-zinc yehlabathi isetyenziswa kule nkqubo.I-zinc ayigcini nje ukwenza i-dense layer yokukhusela kwi-steel surface, kodwa nayo inefuthe lokukhusela i-cathodic.Xa i-coating ye-zinc yonakalisiwe, isenokuthintela ukubola kwesiseko sentsimbi ngokukhuselwa kwe-cathodic.

2. Ukugoba okuhle okubandayo kunye nokusebenza kwe-welding: ubukhulu becala isetyenziselwe ibakala lentsimbi ephantsi yekhabhoni, iimfuno zinokugoba okubandayo okubandayo kunye nokusebenza kwewelding, kunye nokusebenza kwesitampu esithile.

3. UkuReflectivity: Inokubonakala okuphezulu, okuyenza ibe ngumqobo ngokuchasene nobushushu

I-4, i-coating toughness inamandla, i-galvanized layer yenza isakhiwo esikhethekileyo se-metallurgical, esi sakhiwo sinokumelana nomonakalo womatshini ekuthuthweni nasekusebenziseni.

Isicelo

Iimveliso zekhoyili ezenziwe ngegalvanized zisetyenziswa ikakhulu kulwakhiwo, kushishino olulula, iimoto, ezolimo, ukufuya izilwanyana, ukuloba noshishino.Ushishino lolwakhiwo lusetyenziselwa ukwenza iipaneli zophahla lwemizi-mveliso kunye nophahla lwezakhiwo ezichasene nomhlwa, iigridi zophahla, njl.njl. Ishishini lokukhanya lilisebenzisa ukwenza iqokobhe lesixhobo sendlu, itshimini yesizwe, izixhobo zasekhitshini, njl. njl., kunye neshishini lemoto ubukhulu becala isetyenziselwa ukwenza iinxalenye zeemoto ezingadleki.Ezolimo, ukufuywa kwezilwanyana kunye nokuloba zisetyenziswa ikakhulu njengokugcinwa kokutya kunye nokuthutha, inyama kunye neemveliso zasemanzini izixhobo zokulungisa umkhenkce, njl.

Iiparamitha

| Igama lemveliso | Umbhobho oGqwethiweyo |

| IBanga | Q235B, SS400, ST37, SS41, A36 njl |

| Ubude | Umgangatho we-6m kunye ne-12m okanye njengemfuno yomthengi |

| Ububanzi | 600mm-1500mm, ngokwemfuno yomthengi |

| Ezobugcisa | Kushushu Dipped Galvanizedumbhobho |

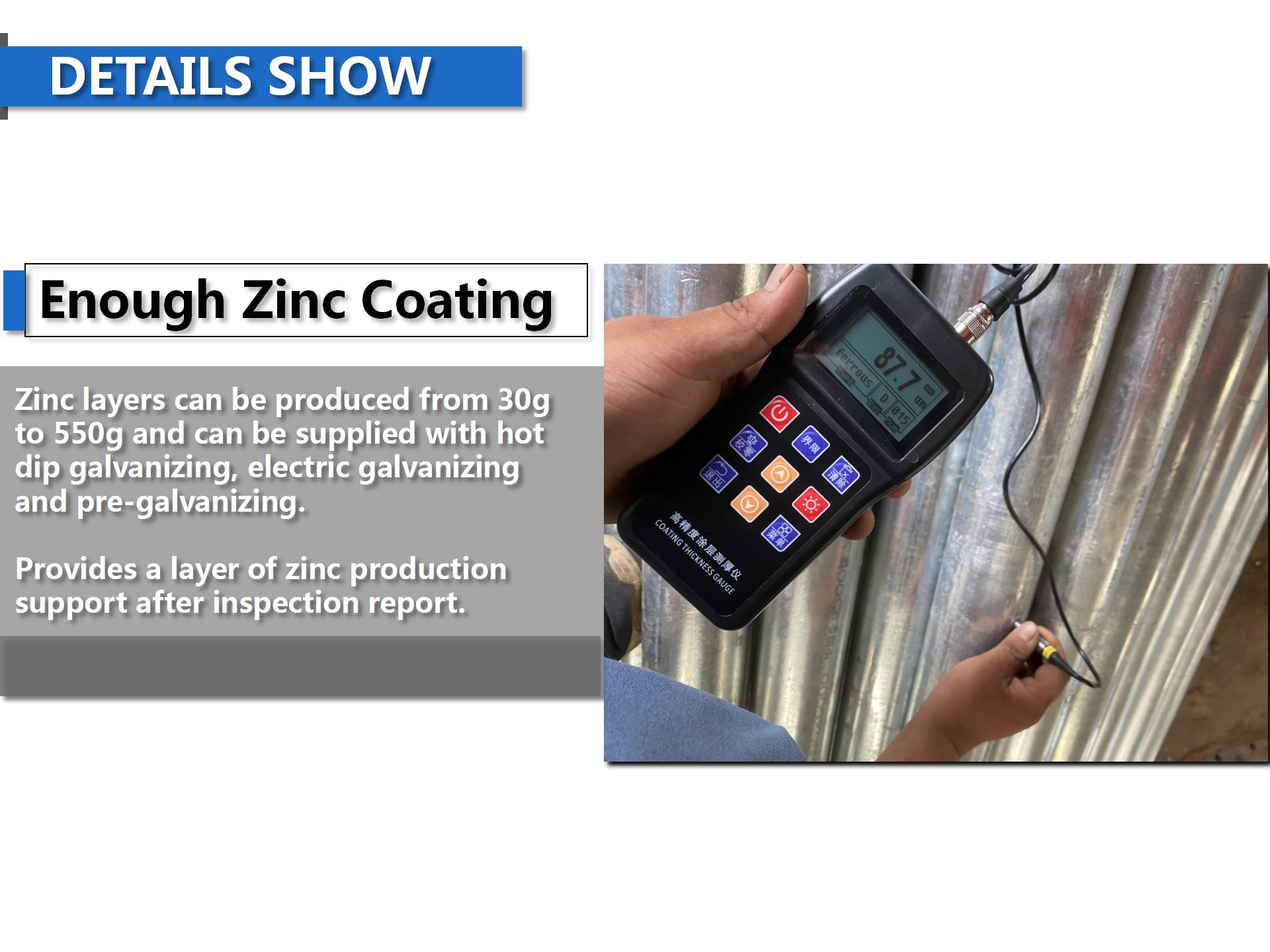

| I-Zinc Coating | 30-275g/m2 |

| Isicelo | Isetyenziswa ngokubanzi kwizakhiwo ezahlukeneyo, iibhulorho, izithuthi, isiqhoboshi, oomatshini njl. |

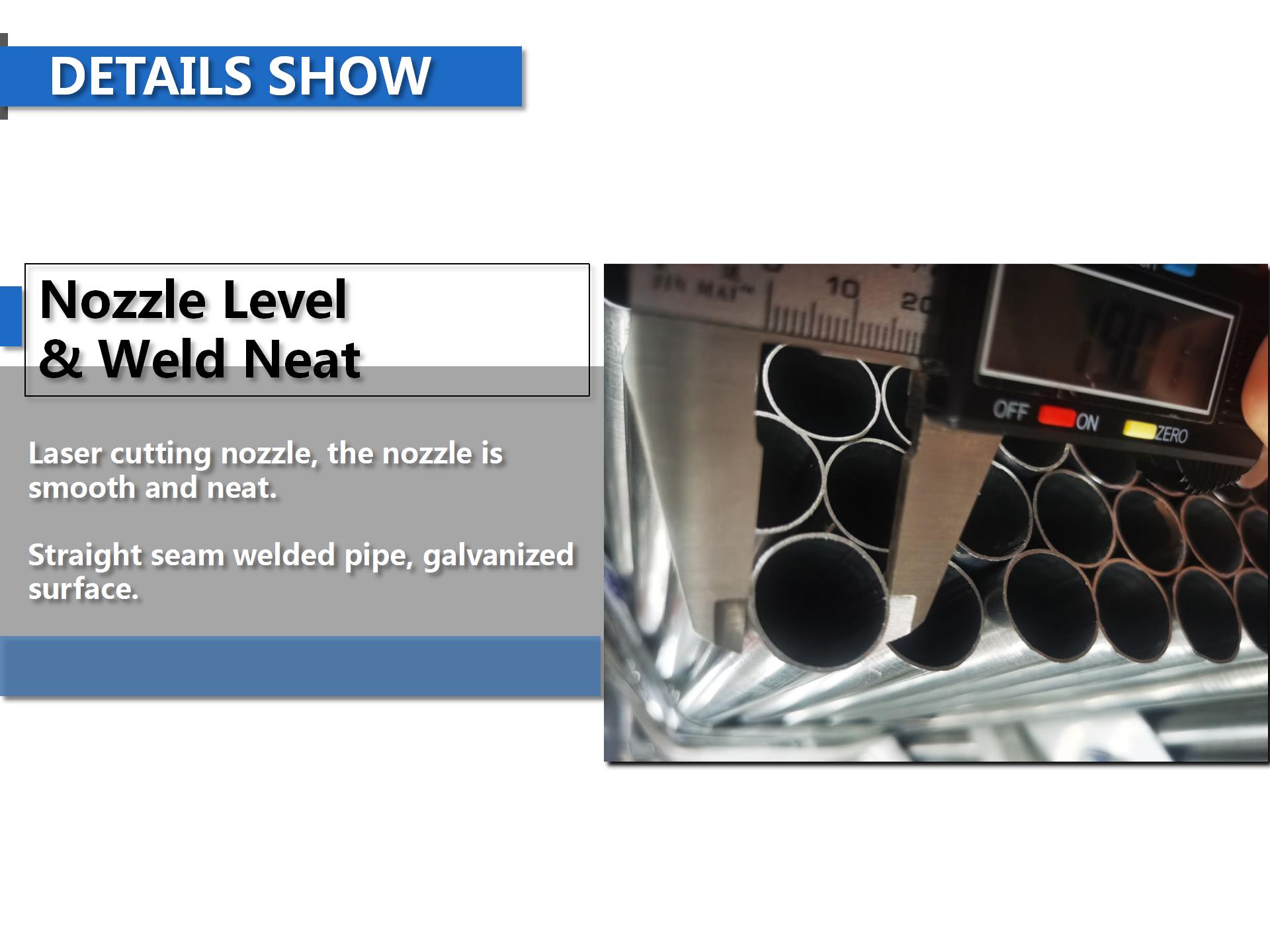

Iinkcukacha

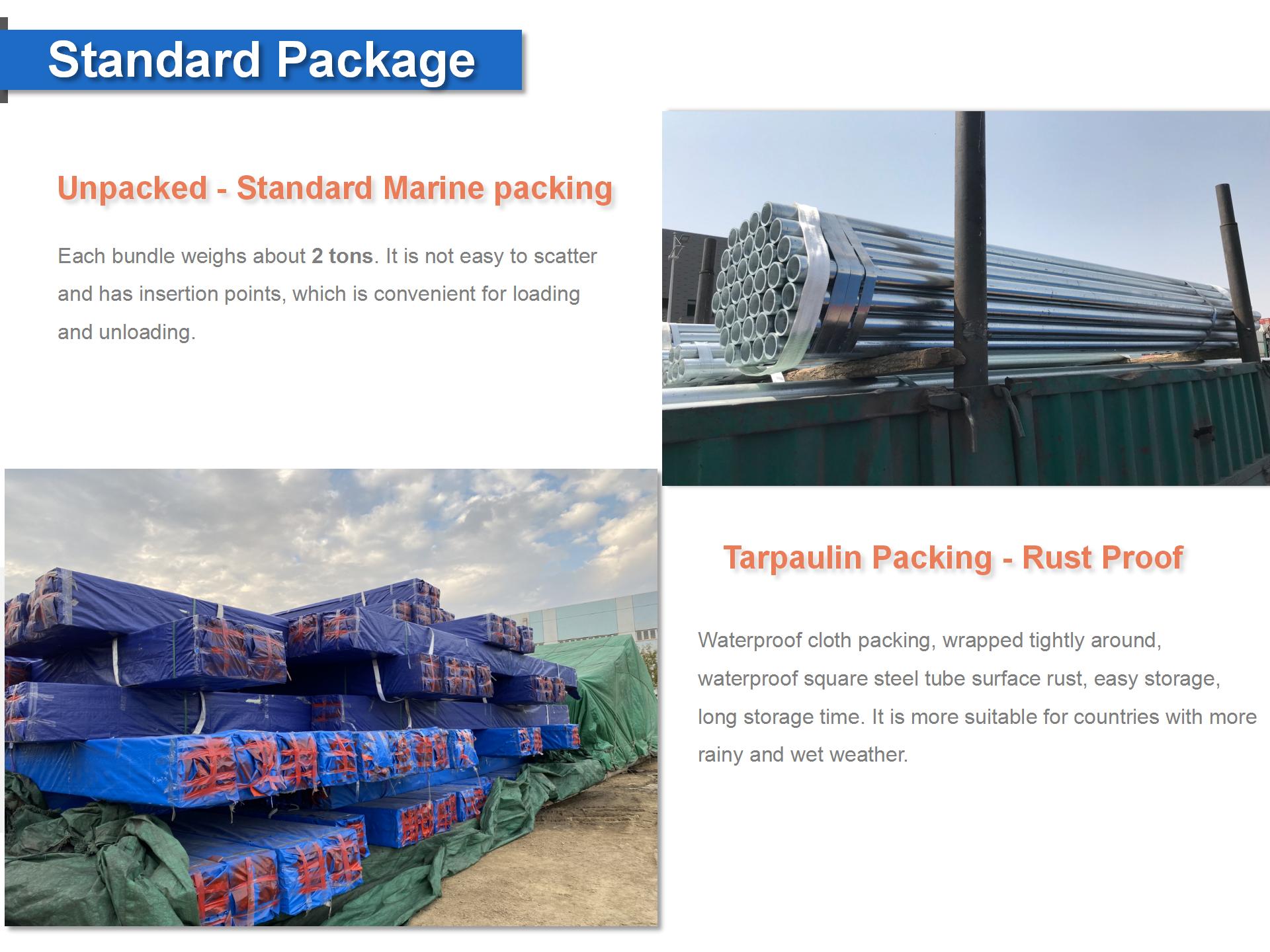

ityhubhu engqukuva yentsimbiukupakishwa ngokuqhelekileyo kubandakanya la manyathelo alandelayo:

1. Imibhobho ejikelezileyo yentsimbi ejikeleziweyo ihlolwe naziphi na iziphene okanye umonakalo ngaphambi kokupakisha.

2. Emva koko sebenzisa isinyithi okanye imitya yeplastiki ukubopha iityhubhu ndawonye ukuze uzibambe zikhuselekile.

3. Emva koko beka iityhubhu ezidityanisiweyo kwiphalethi okanye kwikhreyithi, uze wongeze ikhadibhodi okanye izikhewu zomthi phakathi komaleko ngamnye wetyhubhu ukunqanda ukukhuhlana ngexesha lokuhamba.

4. Iphalethi okanye ikhreyithi ke isongelwe ngefilimu yeplastiki ekhuselayo ukuze ikhuseleke ngakumbi ityhubhu kwaye ithintele nakuphi na ukufuma okanye inkunkuma ukuba ingangeni ngaphakathi.

5. Ekugqibeleni, ityhubhu ifakwe ngolwazi olufana nobukhulu, ubuninzi kunye naluphi na olunye ulwazi olufanelekileyo ekuncediseni ukugcinwa kunye nokuchongwa kwindawo ekuyiyo.

Ukupakishwa ngokufanelekileyo kwemibhobho engqukuva yentsimbi egutyungelweyo kubaluleke kakhulu ukuqinisekisa ukuba ifika kwindawo yayo ikwimeko entle inomonakalo omncinci okanye umhlwa.

1. Athini amaxabiso akho?

Amaxabiso ethu axhomekeke ekutshintsheni ngokuxhomekeke kubonelelo kunye neminye imiba yemarike.Siza kukuthumelela uluhlu lwamaxabiso oluhlaziyiweyo emva koqhagamshelwano lwenkampani yakho

nathi ngolwazi oluthe kratya.

2. Ingaba unomlinganiselo ophantsi weodolo?

Ewe, sifuna zonke ii-odolo zamazwe ngamazwe ukuba zibe ne-odolo encinci eqhubekayo.Ukuba ujonge ukuthengisa kwakhona kodwa ngexabiso elincinci kakhulu, sicebisa ukuba ujonge iwebhusayithi yethu

3. Unganikezela ngamaxwebhu afanelekileyo?

Ewe, sinokubonelela ngamaxwebhu amaninzi aquka iziQinisekiso zoHlahlelo / zokuThobela;I-inshurensi;Imvelaphi, kunye namanye amaxwebhu okuthumela ngaphandle apho kuyimfuneko.

4. Ithini i-avareji yexesha lokukhokela?

Kwiisampuli, ixesha lokukhokela limalunga neentsuku ezi-7.Ukuveliswa kobuninzi, ixesha lokukhokela liyi-5-20 iintsuku emva kokufumana intlawulo yediphozithi.Amaxesha okukhokela ayasebenza xa

(1) siyifumene idiphozithi yakho, kwaye (2) sinemvume yakho yokugqibela yeemveliso zakho.Ukuba amaxesha ethu okukhokela akasebenzi kunye nomhla wakho obekiweyo, nceda ujonge iimfuno zakho ngentengiso yakho.Kuzo zonke iimeko siya kuzama ukulungiselela iimfuno zakho.Kwiimeko ezininzi siyakwazi ukwenjenjalo.

5. Zeziphi iintlobo zeendlela zokuhlawula ozamkelayo?

I-30% kwangaphambili nge-T / T, i-70% iya kuba phambi kokuthunyelwa kwesiseko kwi-FOB;I-30% kwangaphambili nge-T/T, i-70% ngokuchasene nekopi ye-BL esisiseko kwi-CIF.